Novel pet wet grain and preparation method thereof

A technology for pets and wet food, applied in animal feed, animal feed, application, etc., can solve the problems of processing methods to limit the form and content of diced meat, and achieve the effect of method improvement and formula optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

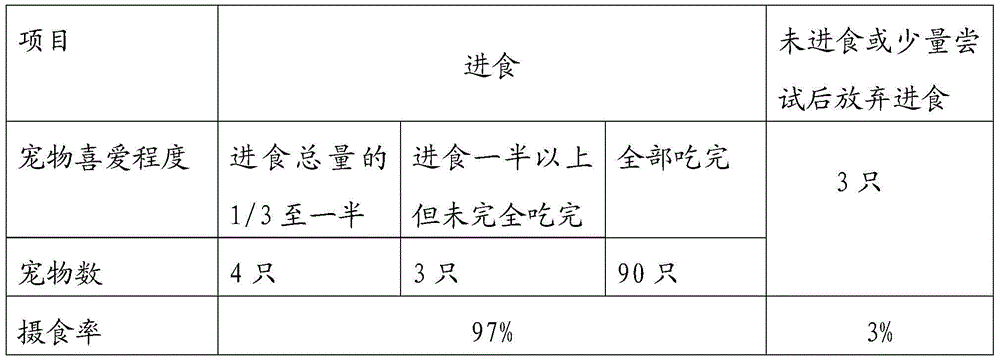

Examples

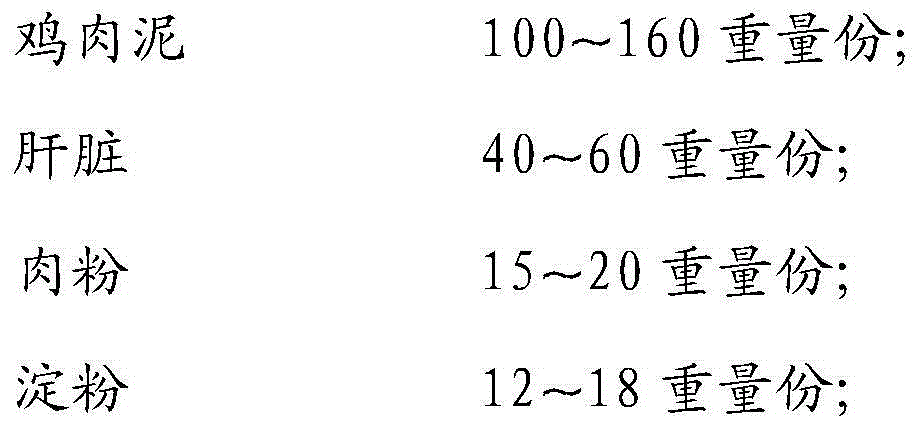

Embodiment 1

[0034] 1. Raw material preparation:

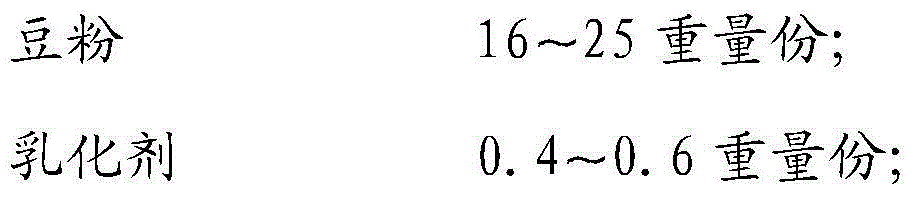

[0035] Sausage material: 160 parts of chicken puree, 60 parts of liver, 20 parts of meat powder, 18 parts of starch, 25 parts of soybean powder, 0.4 parts of propylene glycol.

[0036] Soup material: xanthan gum 1.0 parts, water 150 parts

[0037] 2. Production steps:

[0038] 1) Chop and mix the chicken puree, liver, meat powder, starch, soybean powder, emulsifier, etc. evenly;

[0039] 2) Pour the uniformly mixed material into the collagen casing through the sausage filling machine to make a small sausage with a length of 2 cm and a diameter of 1.7 cm;

[0040] 3) steaming the finished small sausages at 70°C for 20 minutes;

[0041] 4) Xanthan gum and water are evenly and fully mixed to form a uniform soup solution;

[0042] 5) After the steamed sausages are separated into individual states, put them into the outer packaging of tinplate cans after cooling, and add the mixed soup solution into the tin cans according to the weight rati...

Embodiment 2

[0046] 1. Raw material preparation:

[0047] Sausage ingredients: 160 parts of chicken paste, 50 parts of liver, 20 parts of meat powder, 12 parts of starch, 25 parts of soybean powder, 0.3 parts of glycerin, 0.3 parts of sodium lactate; accessories: 0.02 parts of potassium sorbate, 1 part of table salt, 0.2 parts of oligosaccharides , 2 parts of compound phosphate, 0.1 part of sodium iso-VC, 1 part of multivitamin, 1 part of compound mineral, 0.2 part of carotene.

[0048] Soup ingredients: 1.4 parts of xanthan gum, 95 parts of water.

[0049] 2. Production steps:

[0050] 1) Chop and mix the minced chicken, liver, meat powder, starch, soybean powder, emulsifier, auxiliary materials, etc.;

[0051] 2) Pour the uniformly mixed material into the collagen casing through the sausage filling machine to make a small sausage with a length of 1.8 cm and a diameter of 1.8 cm;

[0052] 3) steaming the finished small sausages at 75°C for 15 minutes;

[0053] 4) Mixing xanthan gum, w...

Embodiment 3

[0058] 1. Raw material preparation:

[0059] Sausage ingredients: 100 parts of chicken paste, 40 parts of liver, 15 parts of meat powder, 15 parts of starch, 16 parts of soybean powder, 0.5 parts of sorbitol; accessories: 0.005 parts of cochineal red, 0.001 parts of sodium diacetate, 0.1 parts of table salt, oligomeric 0.1 parts of sugar.

[0060] Soup ingredients: 95 parts of water, 0.5 part of guar gum, and 0.8 part of carrageenan.

[0061] 2. Production steps:

[0062] 1) Chop and mix the chicken puree, liver, meat powder, starch, soybean powder, emulsifier, etc. evenly;

[0063] 2) Pour the uniformly mixed material into the collagen casing through a sausage filling machine to make a sausage string consisting of small sausages with a length of 2.2 cm and a diameter of 1.6 cm;

[0064] 3) steaming the formed sausage skewers at 75°C for 20 minutes;

[0065] 4) Mix guar gum, carrageenan, and water evenly into a homogeneous solution state;

[0066] 5) After separating the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com