Protein production accelerator

一种闪烁体、闪烁体层的技术,应用在摄影工艺、X射线/红外工艺、仪器等方向,能够解决发光不均、X射线荧光体体积变小、空间变窄等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

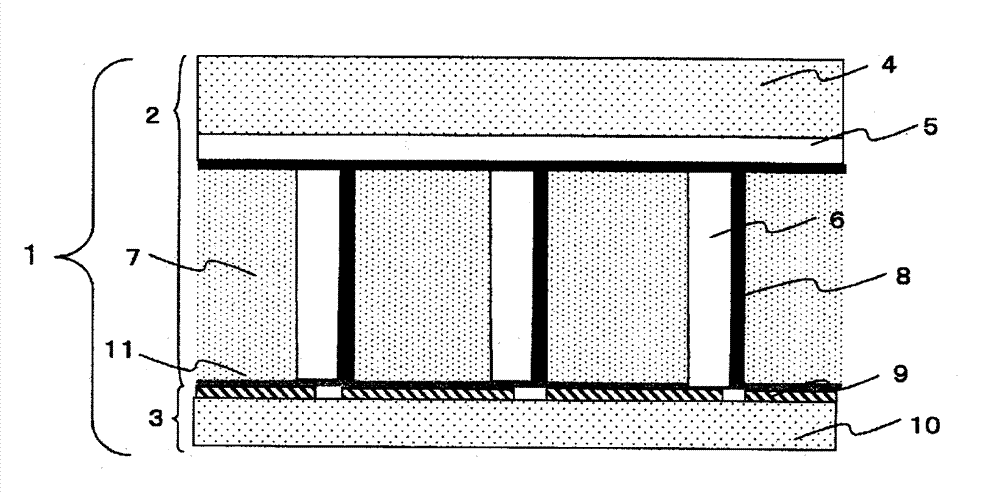

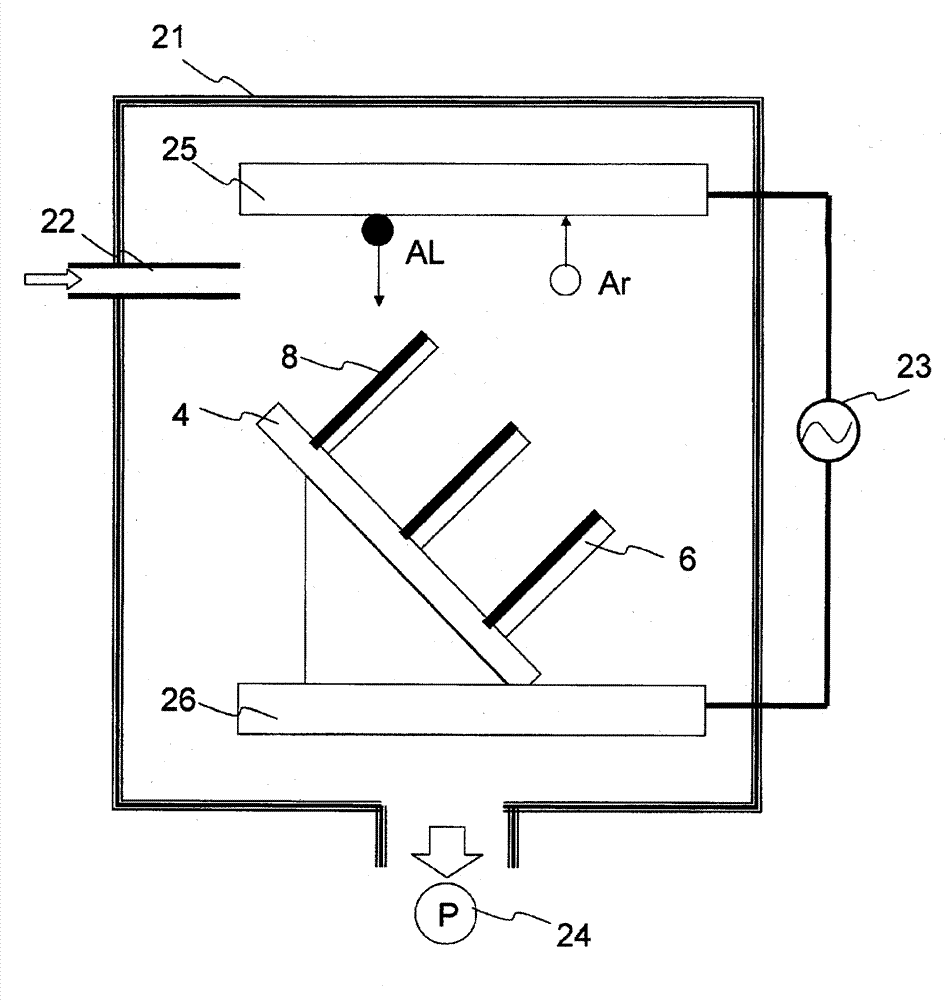

[0140] On a glass substrate (AGC Asahi Glass Co., Ltd.; AN-100) of 500mm×500mm×thickness 0.5mm, the above-mentioned base paste was coated with a 15μm bar coater, dried at 150°C for 30 minutes, and heat-cured. A base paste film with a thickness of 12 μm was formed. Next, the photosensitive paste for partition walls was coated with a die coater so as to have a dried thickness of 500 μm, and dried at 120° C. for 30 minutes to form a photosensitive paste coating film for partition walls.

[0141] Next, through a photomask (a chrome mask having grid-like openings with a line width of 10 μm and a vertical and horizontal pitch of 125 μm) formed with openings corresponding to the desired partition rib pattern, the photomask was heated at 700 mJ / cm using an ultra-high pressure mercury lamp. 2 The exposure amount of the photosensitive paste coating film for partition walls was exposed. The exposed photosensitive paste coating film for barrier ribs was developed in 0.5% aqueous ethanola...

Embodiment 2)

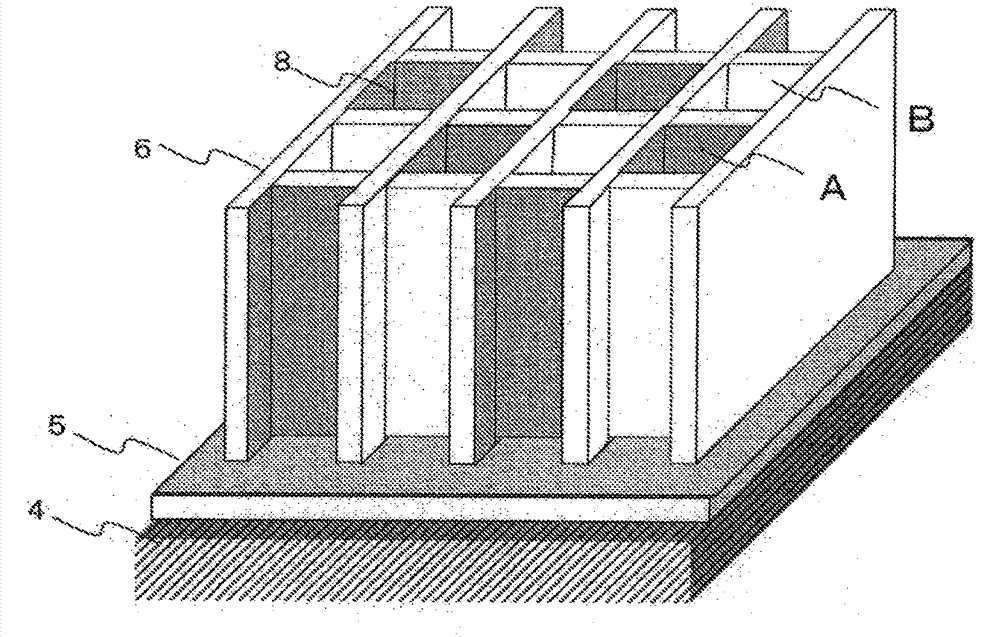

[0150] A substrate on which lattice-shaped partition walls were formed was produced by the same method as in Example 1. After apply|coating the said paste 2 for photosensitive reflection layers to the whole surface of a partition by the screen printing method, it dried at 120 degreeC for 30 minutes. Next, a mask having openings corresponding to the desired reflective layer formation pattern (both vertical and horizontal pitches are 125 μm; 125 μm square openings and light-shielding sections are alternately arranged) is arranged so that the openings coincide with the cells, Use an ultra-high pressure mercury lamp at 500mJ / cm 2 Exposure at the exposure level. The exposed photosensitive reflective layer paste coating film was developed in a 0.5% ethanolamine aqueous solution to remove unexposed portions to form a grid-like photosensitive reflective layer paste coating film pattern. Furthermore, it baked in air at 500 degreeC for 15 minutes. The result is as figure 2 As shown...

Embodiment 3)

[0153] By the same method as in Example 1, the base paste film and the photosensitive paste coating film for partition walls were formed on the glass substrate.

[0154] Next, exposure and exposure were performed under the same conditions as in Example 1 through a photomask (a photomask having stripe-shaped openings with a pitch of 125 μm and a line width of 10 μm) in which openings corresponding to the desired partition rib pattern were formed. Developed to form a striped photosensitive paste coating film pattern. Furthermore, the photosensitive paste coating film pattern was calcined in air at 595° C. for 15 minutes to produce a film having a partition wall spacing L2 of 125 μm, a top width L4 of 15 μm, a bottom width L3 of 30 μm, and a partition wall height L1 formed on the surface. A substrate with stripe-shaped partition walls of 330 μm and a size of 480 mm×480 mm. The transmittance of light having a wavelength of 550 nm at a thickness of 30 μm of the partition wall was ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com