Defect detecting method for junction surface of metal alloy

A metal alloy, defect detection technology, applied in the direction of using sound wave/ultrasonic wave/infrasonic wave to analyze solids, etc., can solve technical difficulties and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the embodiments and accompanying drawings.

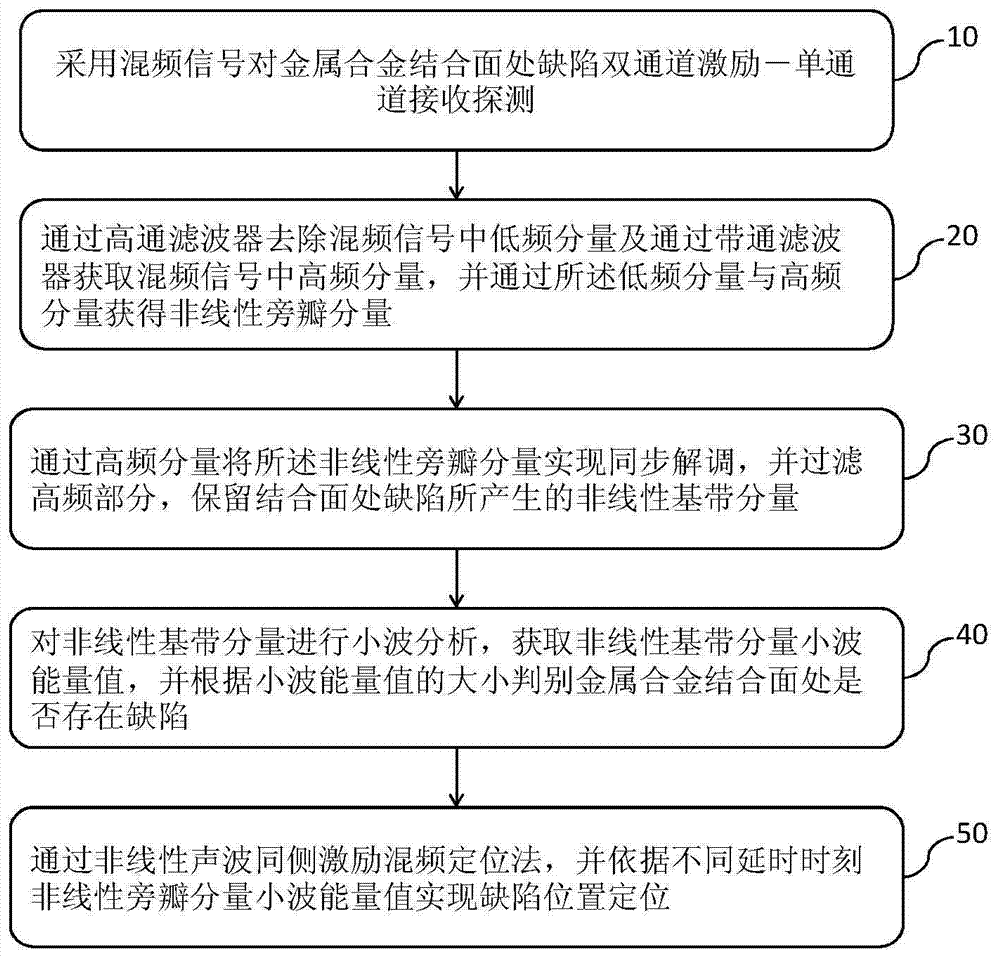

[0027] see figure 1 , the present embodiment provides a metal alloy bonding surface detection method, the method comprising the following steps:

[0028] Step 10: Use the mixed frequency signal to excite the defects at the joint surface of the metal alloy through dual-channel excitation-single-channel receiving detection;

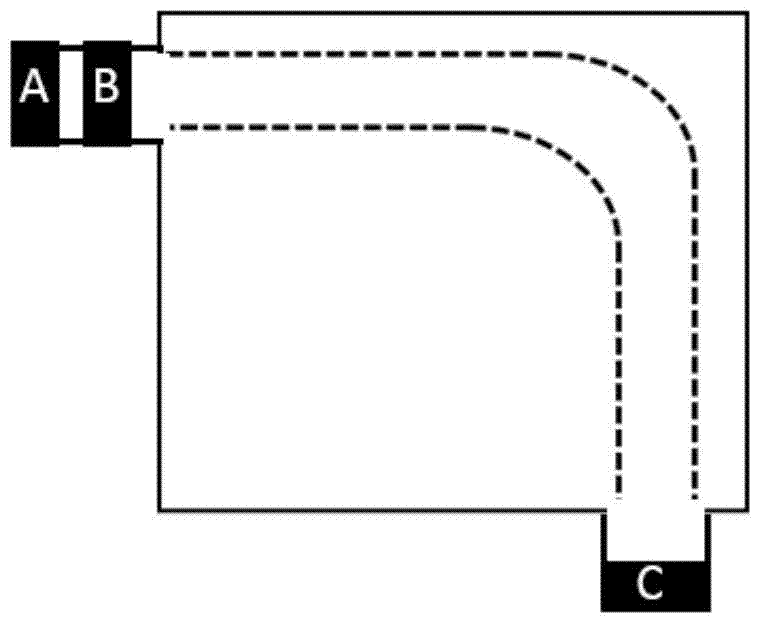

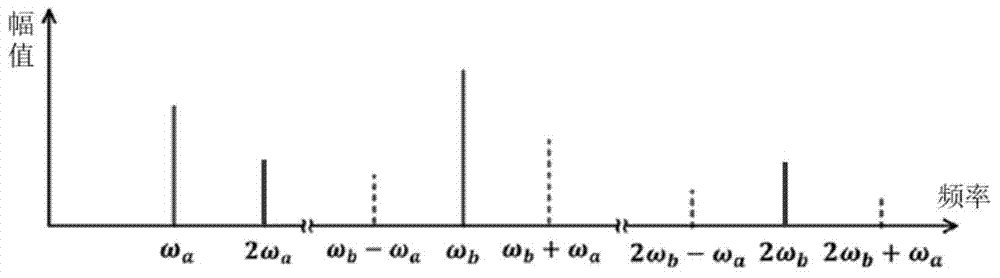

[0029] Active stress wave detection technology and nonlinear modulation guided wave technology are adopted. Both the sending and receiving sensors use PZT transducers with positive and negative piezoelectric effects. Taking the metal structure of cast alloy pipe inside as an example, the dotted line is the alloy joint surface of the buried pipe , the outer layer is metal copper, the inner layer is metal nickel aluminum alloy, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com