Shielding glass defect detection method

A technology for shielding glass and glass defects, applied in measuring devices, material analysis through optical means, instruments, etc., can solve problems that need to be improved, and achieve the effect of preventing defects, preventing leakage, and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

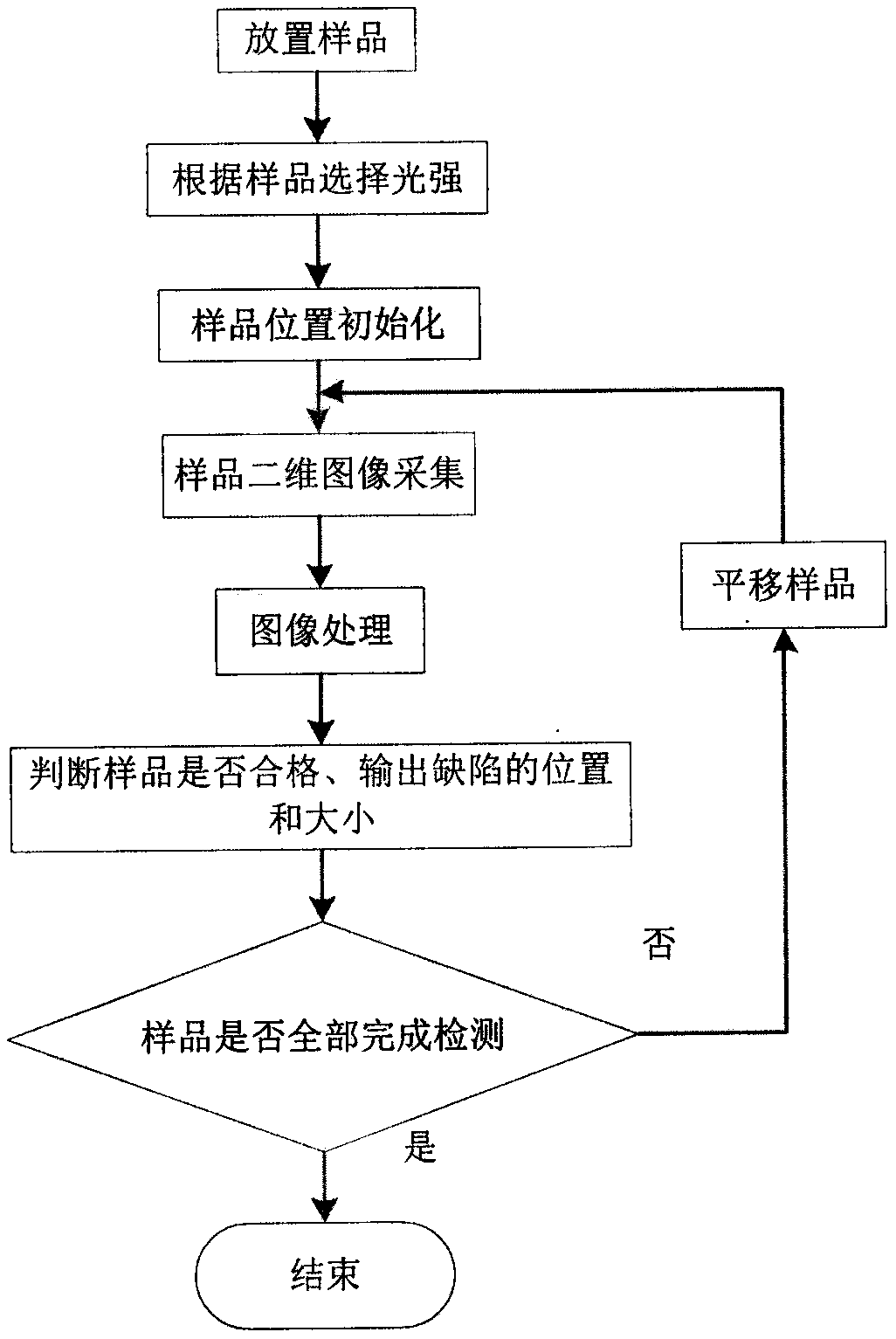

[0037] Embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

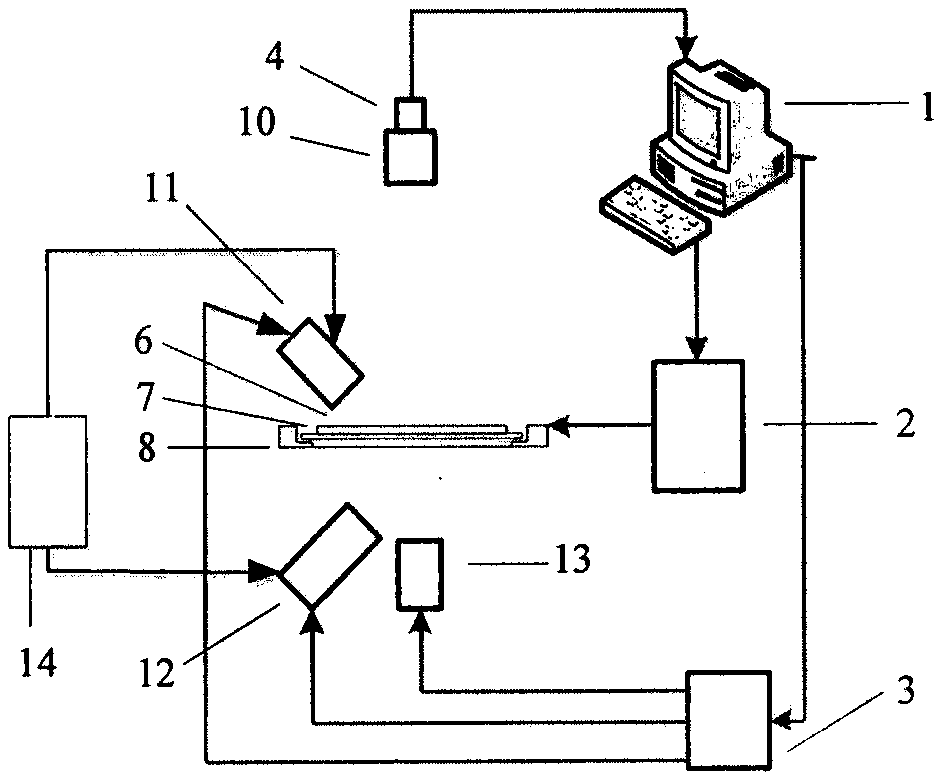

[0038] The embodiment of the present invention proposes a scheme for detecting shielding glass defects by combining illumination with multiple light sources.

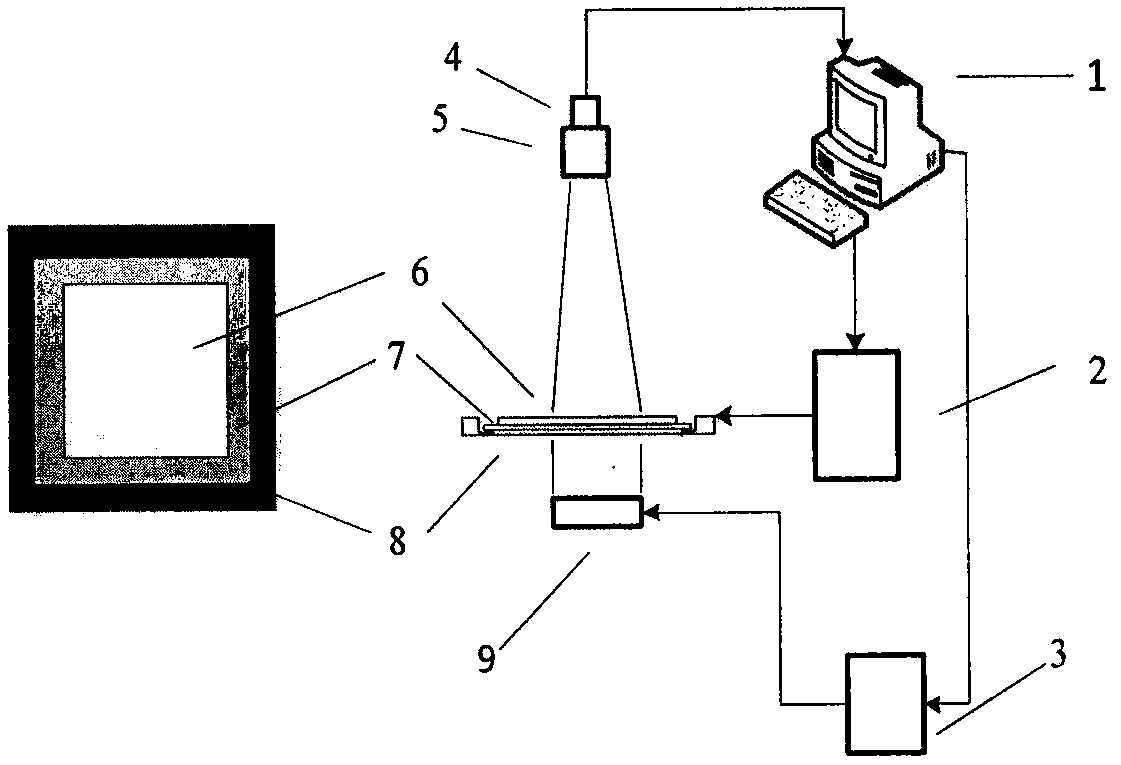

[0039] The composition of the uniform background light illumination shielding glass defect detection system is as follows: figure 1 As shown, the shielding glass 6 is fixed on the bracket 7 of the two-dimensional electric workbench 8, a white highlight background light 9 is placed under the workbench for vertical illumination, and a high-resolution industrial area scan camera 4 and a high-resolution The industrial lens 5 collects images and transmits them to the computer 1. At the same time, the computer is connected to a two-axis controller 2 and a light source controller 3. The two-axis controller 2 controls the movement of the electric workbench 8, and the light source controller 2 controls the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com