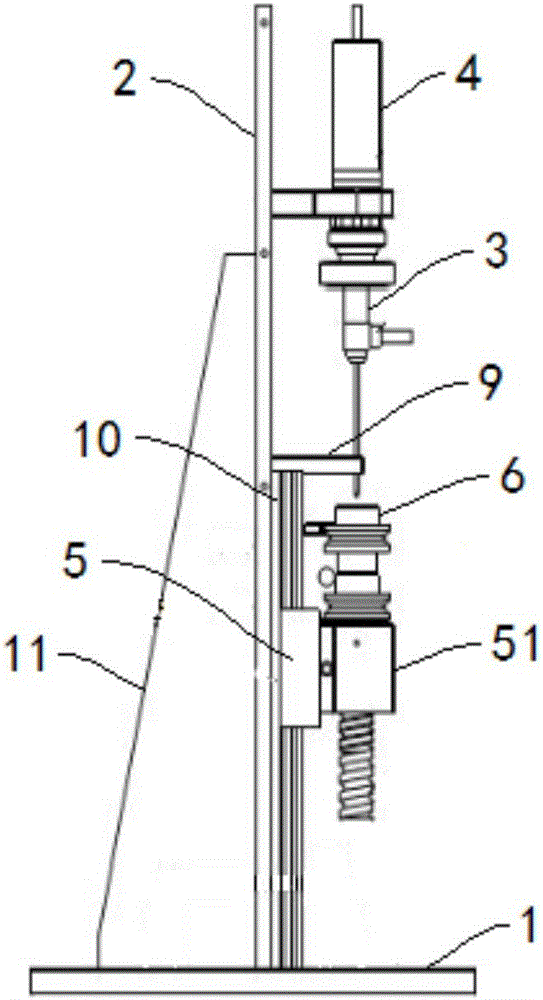

Automatic detection system and automatic detection method for workpiece defects

An automatic detection and workpiece technology, applied in the direction of optical testing flaws/defects, measuring devices, material analysis through optical means, etc., can solve the problems of complex digital image acquisition and low degree of automation, and achieve the effect of automatic detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 8

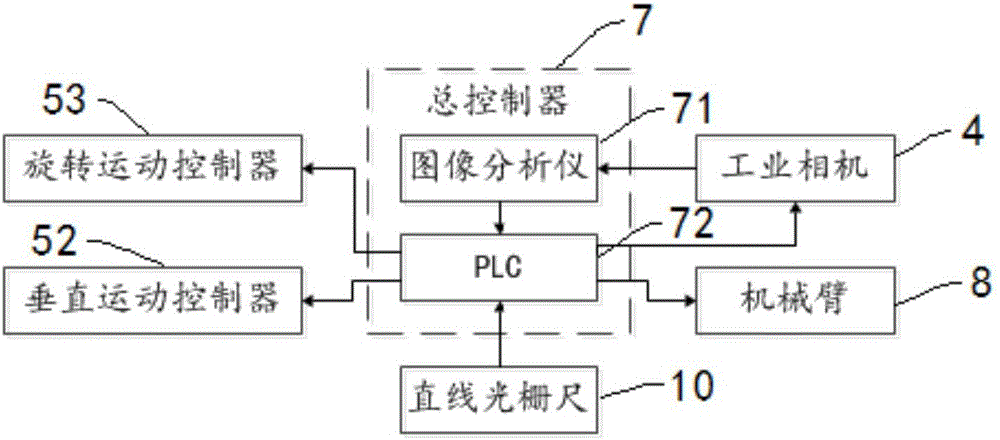

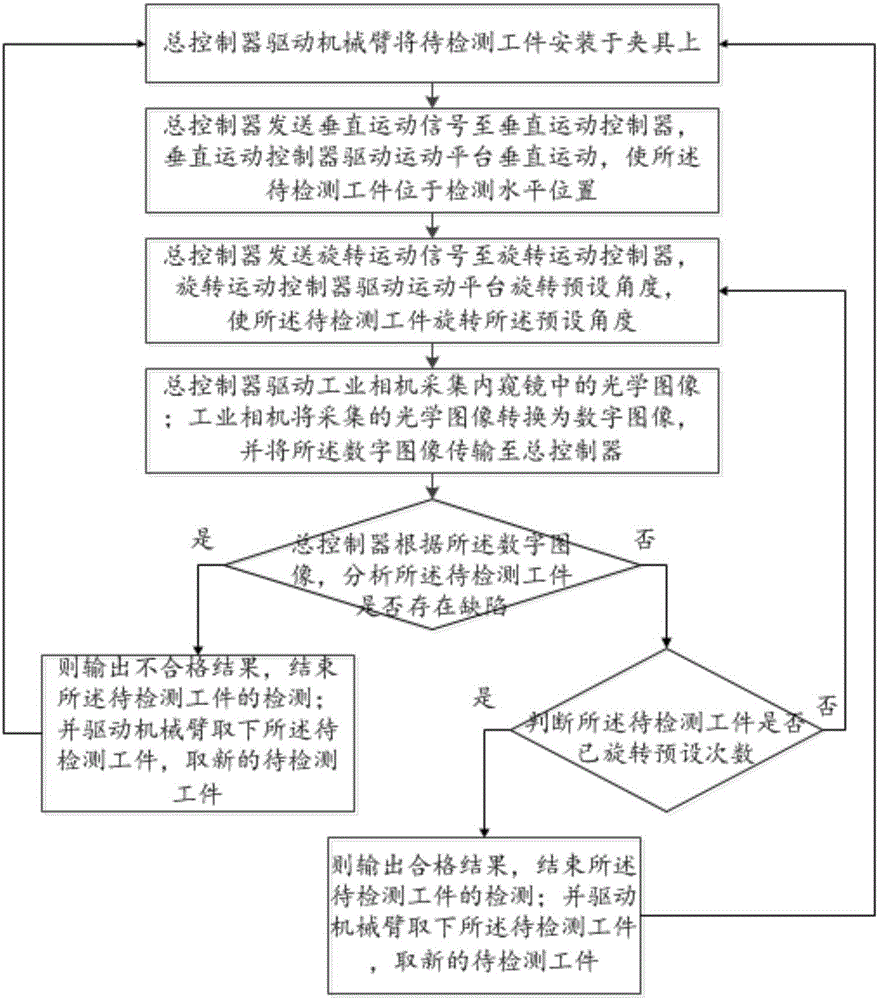

[0072] The method for automatic detection of workpiece defects described in Embodiment 8 of the present invention, on the basis of Embodiment 7, the general controller 7 includes an image analyzer 71 and a PLC 72;

[0073] The further concrete realization of described step 2 comprises the following steps:

[0074] Step b21, PLC72 sends a vertical motion signal to the vertical motion controller 52, and the vertical motion controller 52 drives the motion platform 5 to move vertically;

[0075] Step b22, the linear grating ruler 10 detects the position coordinates of the workpiece 6 to be detected, and transmits the position coordinates to the PLC72;

[0076] In step b23, the PLC 72 compares the position coordinates with the detected horizontal position coordinates, and if the error is smaller than the preset value, then execute step 3; otherwise, return to execute step b21.

Embodiment 9

[0077] The method for automatic detection of workpiece defects described in Embodiment 9 of the present invention, on the basis of Embodiment 6, the general controller 7 includes an image analyzer 71 and a PLC 72;

[0078] The specific implementation of the step 3 is that the PLC72 sends a rotation motion signal to the rotation motion controller 53, and the rotation motion controller 53 drives the motion platform 5 to rotate a preset angle, so that the workpiece 6 to be detected rotates the preset angle;

[0079] The step 4 is specifically implemented as PLC72 drives the industrial camera 4 to collect the optical image in the endoscope 3; the industrial camera 4 converts the collected optical image into a digital image, and transmits the digital image to the image analyzer 71;

[0080] The step 5 is specifically implemented as the image analyzer 71 receiving the digital image, and analyzing whether there is a defect in the workpiece 6 to be detected according to the digital ima...

Embodiment 11

[0087] The method for automatic detection of workpiece defects described in Embodiment 11 of the present invention, on the basis of Embodiment 10,

[0088] The step S1 is specifically realized by performing brightness non-uniformity correction on the digital image by using a frequency domain homomorphic filtering operation to obtain a brightness corrected image.

[0089] According to the illumination reflection model, the digital image is represented by the following first formula;

[0090] The first formula is as follows:

[0091] f(x,y)=i(x,y)r(x,y)

[0092] Wherein, the f (x, y) is the light intensity of the digital image, the i (x, y) is the incident component of the light intensity of the digital image, and the r (x, y) is the reflection component of the light intensity of the digital image;

[0093] According to the following second formula, the digital image is corrected for brightness non-uniformity by using a frequency-domain homomorphic filtering operation to obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com