Control system and control method for reducing smoke in transient conditions of diesel engine

A control system and transient working condition technology, applied in engine control, electrical control, fuel injection control, etc., can solve problems such as smoke deterioration, torque response lag, etc., to improve emissions, reduce lag, and increase in-cylinder heat status effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

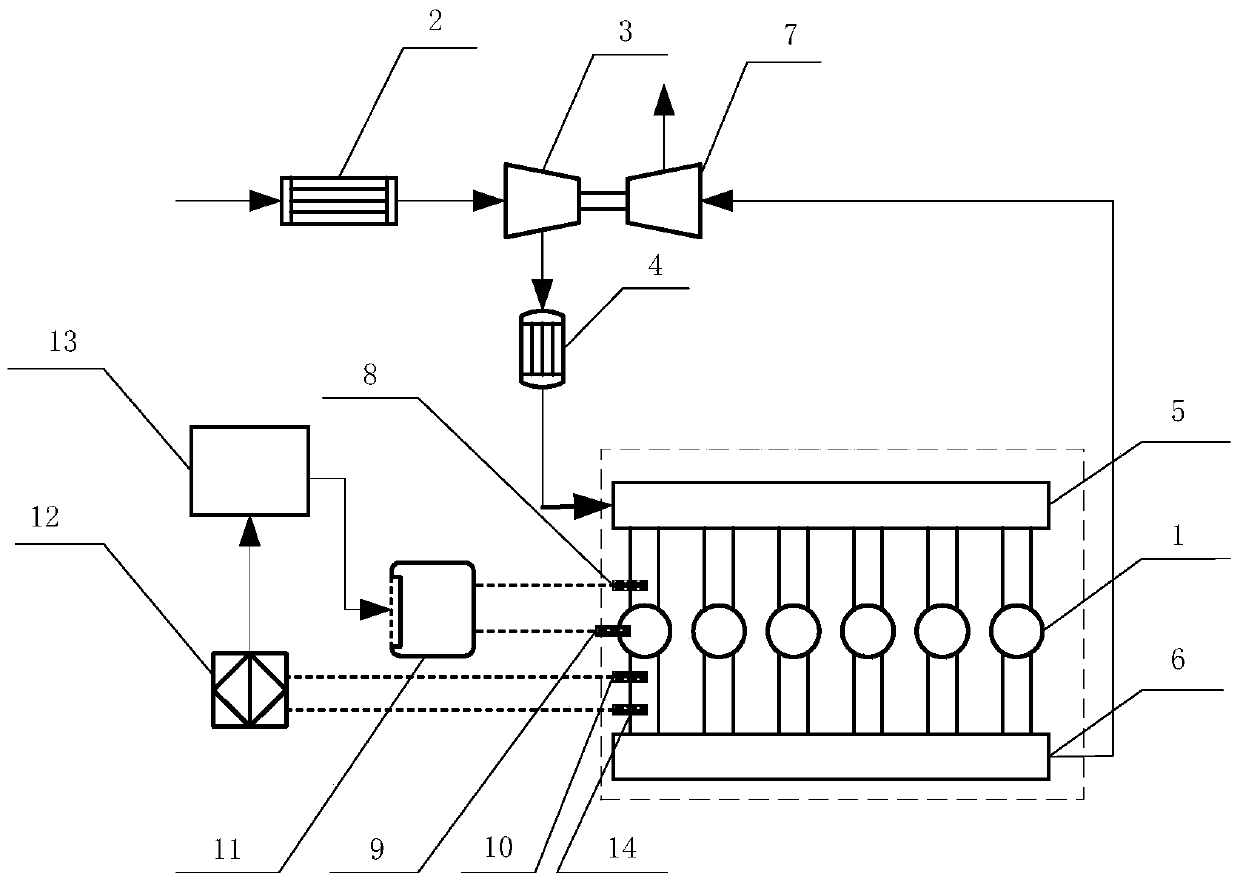

[0035] refer to figure 1 , a control system for reducing smoke in transient operating conditions of a diesel engine, including an engine 1, an air filter 2, a compressor 3, a turbine 7 coaxially connected with the compressor 3, an air intake intercooler 4, and an output High-response speed sensor 8 and high-response torque sensor 9 on the shaft, cylinder pressure sensor 10 installed on the cylinder block, ECU electronic control unit 11, charge amplifier 12, single-chip microcomputer 13 with CA50 calculation program, installed on the engine flywheel The crankshaft position sensor 14;

[0036] The air filter 2 is communicated with the intake manifold 5 on the engine 1 through the compressor 3 and the air intake intercooler 4 in sequence, and the turbine 7 is communicated with the exhaust manifold 6 on the engine 1 ;

[0037] The high-response speed sensor 8 and the high-response torque sensor 9 are respectively connected to the ECU electronic control unit 11 in communication; ...

Embodiment 2

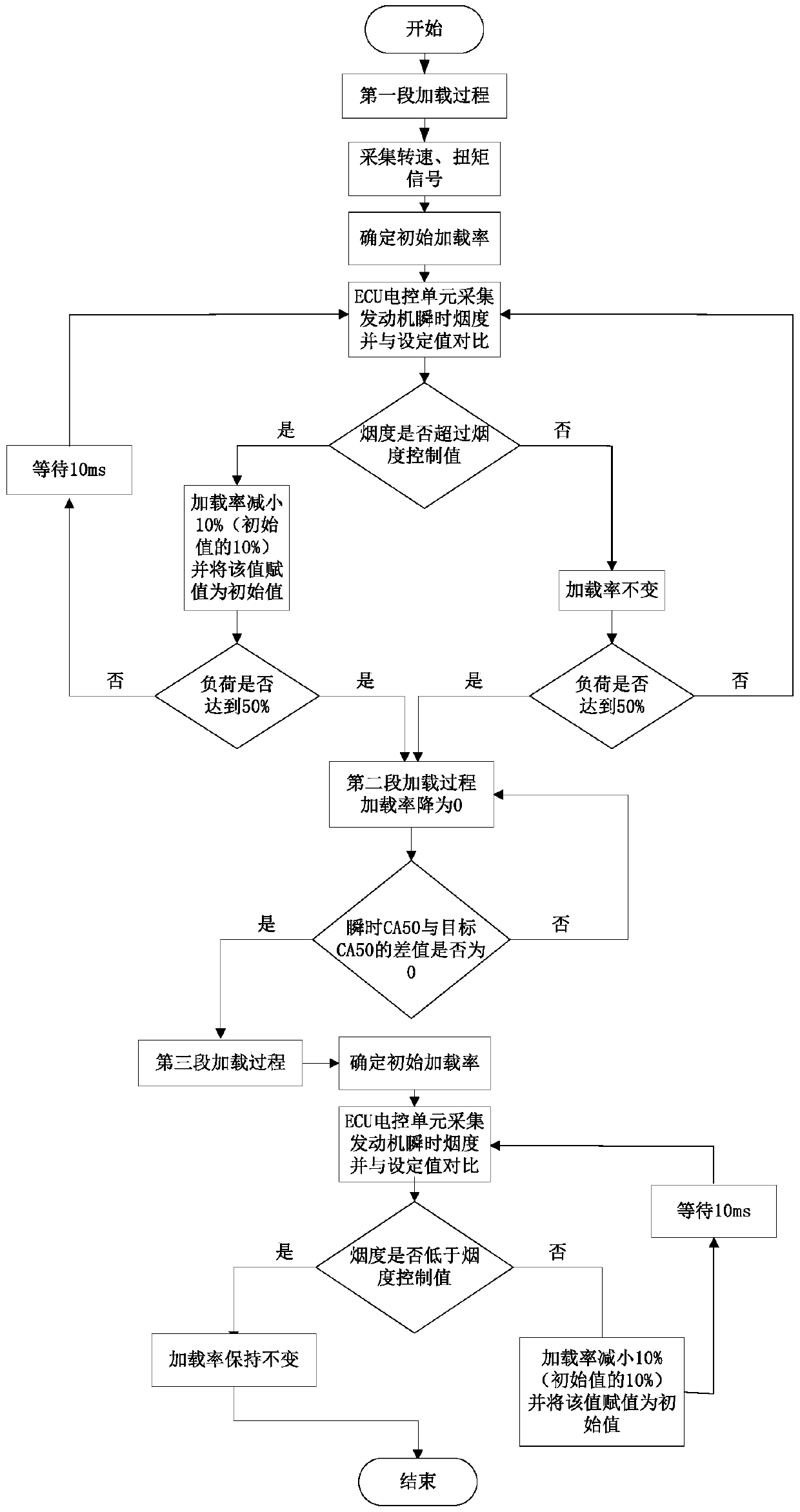

[0040] A closed-loop control method based on the control system of the present invention is based on smoke and CA50 (the crankshaft angle corresponding to 50% mass fraction of diesel fuel combustion) as control targets, and adopts a three-stage broken-line loading strategy to adjust the fuel supply rate to achieve the loading rate (unit time torque rate of change), including the following steps: (refer to figure 2 )

[0041] 1), first, according to the engine development requirements, set the smoke level target value and the CA50 target value of each working condition in the ECU electronic control unit 11;

[0042] 2), the ECU electronic control unit 11 collects the engine torque signal through the high-response torque sensor 9, and calculates the initial loading rate of the engine according to the loading rate calculation formula (1), and performs the first stage loading on the engine with this loading rate,

[0043]

[0044] Where: ΔT tq is the change value of the torque...

Embodiment 3

[0054] A diesel engine runs at a constant speed with increased torque (loading), where the constant speed is 1650r / min, the torque increases from 10% of the maximum torque value to 100%, that is, from 10% load to 100% load, and the loading time is 5s; According to the actual needs of the engine, the smoke target value is 10%.

[0055] 1. First, according to the requirements of engine development, set the target value of smoke level in the ECU electronic control unit to 10% and input the CA50 value of each working condition;

[0056] 2. The ECU electronic control unit collects the engine torque signal through the high-response torque sensor, and uses the loading rate calculation formula (1) to calculate the initial loading rate of the engine as 665N·m / s, and uses this loading rate for the first stage of loading. At this time, the ECU electronic control unit collects the instantaneous smoke level of the engine as 12%, which exceeds the smoke target value by 10%. The ECU electron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com