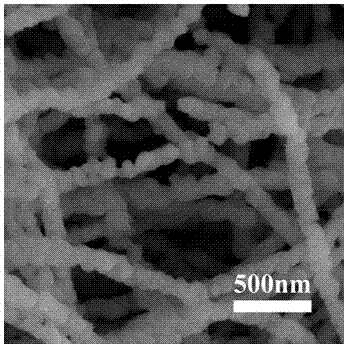

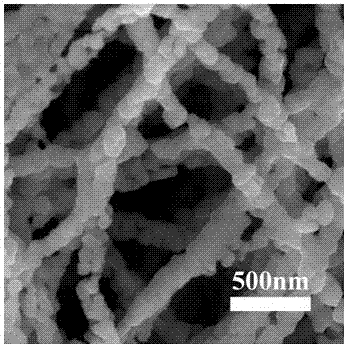

Cobaltosic oxide bead-chain-shaped fiber and preparation method thereof

A technology for cobalt tetroxide beads and fibers, which is applied in the chemical characteristics of fibers, chemical post-processing of rayon, textiles and papermaking, etc., can solve the problem of unobtained one-dimensional structure of cobalt tetroxide, achieves wide application prospects, simple and controllable preparation process, tight connection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1.1 Weigh 0.5 g Co(NO 3 ) 2 ·6H 2 O was added to a beaker containing 12 mL of N, N dimethylformamide, and stirred until the cobalt source was completely dissolved;

[0026] 1.2 Add 1.5 g of PVP to the solution prepared in 1.1, and stir to obtain a transparent and uniform spinning dope with a certain viscosity;

[0027] 1.3 Put the spinning solution obtained in 1.2 into a syringe, use a needle with a diameter of 0.6 mm as the spinneret for spinning, the voltage of the electrospinning process is 15 kV, the distance between the needle and the receiving plate is 12 cm, and the spinning The propulsion speed of the liquid is 0.42 mL / h, and a certain receiving device is used to receive the Co(NO 3 ) 2 / PVP composite nanofiber;

[0028] 1.4 Put the composite nanofibers obtained in 1.3 into a programmable temperature-controlled furnace, and adopt the segmental calcination method, that is, the first stage uses a heating rate of 1°C / min to heat to 400°C, and the second stage ...

Embodiment 2

[0030] 2.1 Weigh 0.6 g Co(NO 3 ) 2 ·6H 2 O was added to a beaker containing 12 mL of N, N dimethylformamide, and stirred until the cobalt source was completely dissolved;

[0031] 2.2 Add 2 g of PVP to the solution prepared in 2.1, and stir to obtain a transparent and uniform spinning stock solution with a certain viscosity;

[0032] 2.3 Put the spinning stock solution obtained in 2.2 into a syringe, use a needle with a diameter of 0.8 mm as the spinneret for spinning, the voltage of the electrospinning process is 12 kV, and the distance between the needle and the receiving plate is 15 cm. The propulsion speed of the liquid is 0.84 mL / h, and a certain receiving device is used to receive the Co(NO 3 ) 2 / PVP composite nanofiber;

[0033] 2.4 Put the composite nanofibers obtained in 2.3 into a programmable temperature-controlled furnace, and adopt the segmental calcination method, that is, the first stage uses a heating rate of 1 °C / min to heat to 300 °C, and the second sta...

Embodiment 3

[0035] 3.1 Weigh 0.66 g Co(NO 3 ) 2 ·6H 2 O was added to a beaker containing 12 mL of N, N dimethylformamide, and stirred until the cobalt source was completely dissolved;

[0036] 3.2 Add 2 g of PVP to the solution configured in 3.1, and stir to obtain a transparent and uniform spinning stock solution with a certain viscosity;

[0037]3.3 Put the spinning solution obtained in 3.2 into a syringe, use a needle with a diameter of 0.7 mm as the spinneret for spinning, the voltage of the electrospinning process is 15 kV, and the distance between the needle and the receiving plate is 15 cm. The propulsion speed of the liquid is 0.84 mL / h, and a certain receiving device is used to receive the Co(NO 3 ) 2 / PVP composite nanofiber;

[0038] 3.4 Put the composite nanofibers obtained in 3.3 into a programmable temperature-controlled furnace, and adopt a segmented calcination method, that is, the first stage uses a heating rate of 5°C / min to heat to 300°C, and the second stage adopt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com