Method for preparation of sucrose-6-acetate from fructosyl transferase

A technology of fructosyltransferase and acetate, which is applied in the field of preparation of sucrose-6-acetate, can solve the problems of high cost, low conversion rate, and many operation steps, and achieve simple operation, low cost, and high separation efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

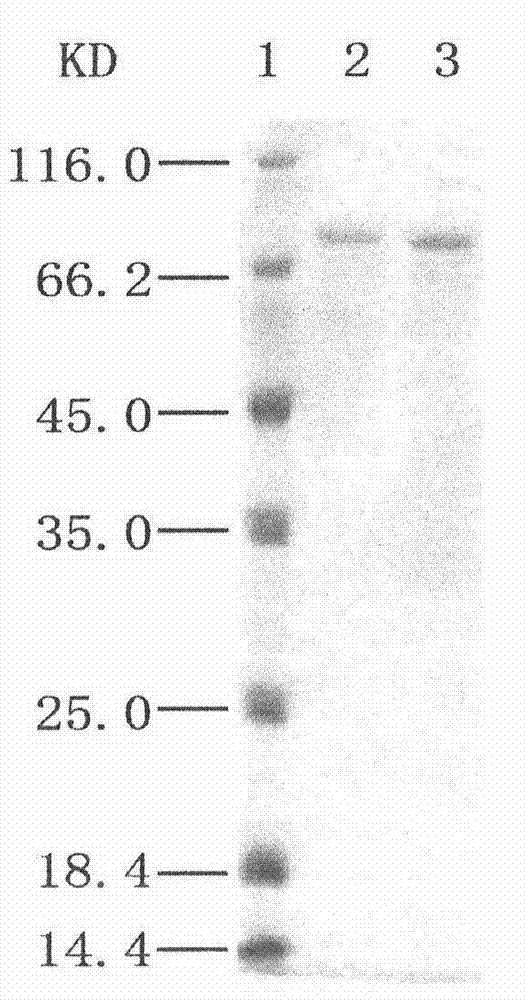

[0047] Embodiment 1, established the method for separating and purifying fructosyltransferase:

[0048] The strain is: Aspergillus oryzae ZZ-01

[0049] The preparation of the culture medium is as follows. In a 1L culture medium: 200g of potatoes, 20g of glucose, 1000mL of water, heated to boiling on a heater for 20min, and filtered with 3 layers of gauze, discarding the filter residue; adding to the filtrate NaNO 3 2g, K 2 HPO 4 1g, KCl 1g, MgSO 4 0.5g, add water to 1000mL, adjust the pH value to 7.0; 28 ℃ constant temperature shaking culture for 48h, and the rotation speed is 200rpm / min, to obtain the bacterial liquid;

[0050] After the bacterial liquid was cultured for 48 hours, the culture was centrifuged at 14,000 rpm for 20 minutes, and the supernatant was collected. The collected supernatant was subjected to fractional precipitation (overnight) with 85% ammonium sulfate, and after centrifugation at 14,000 rpm for 20 min, the precipitate was resuspended in 0.02M ph...

Embodiment 2

[0054] Embodiment 2, the method for the immobilization enzyme of fructosyltransferase:

[0055] The magnetic chitosan microspheres were prepared by combining the inverse suspension method and the sol-gel method, and using this as a carrier, genipin as a cross-linking agent, immobilized the purified fructosyltransferase, the specific method is as follows:

[0056] The preparation of magnetic chitosan microspheres: in a capacity of 1000mL there-necked flask, add oil phase (150mL kerosene+3.5g Tween 80), start stirrer (stirring speed 600r / min), slowly add 90g magnetic chitosan solution ( The concentration of acetic acid is 2%, the concentration of chitosan (deacetylation degree 85-90%, Sinopharm Chemical Reagent Co., Ltd.) is 4%, Fe 3 o 4 content of 5%), stirred continuously for 1 hour to form a uniform water-in-oil emulsion, then quickly added to the condensate (V (2mol / L NaOH): V (ethanol) = 4: 1), kept magnetic stirring for 30 minutes, and stopped Stir, let stand overnight, ...

Embodiment 3

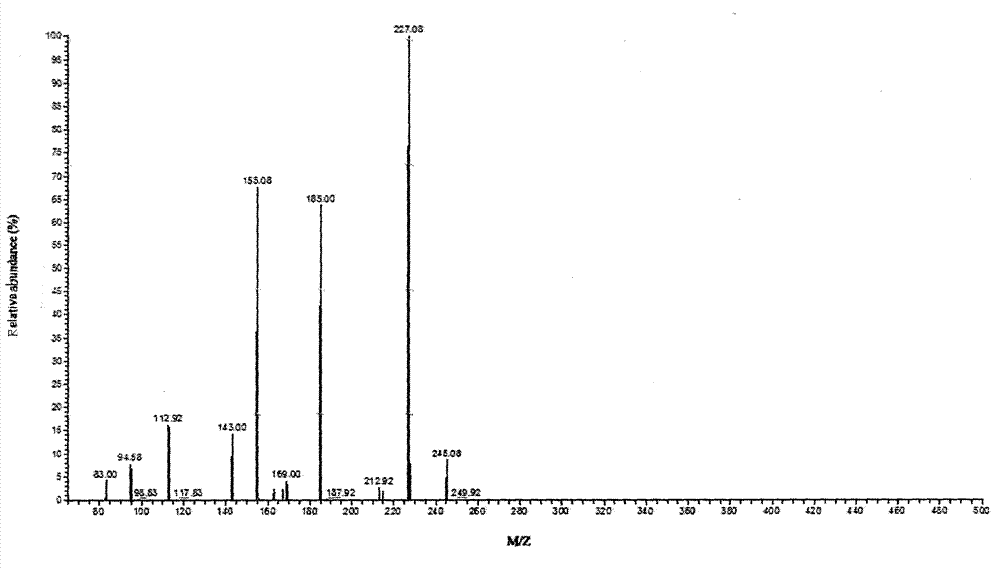

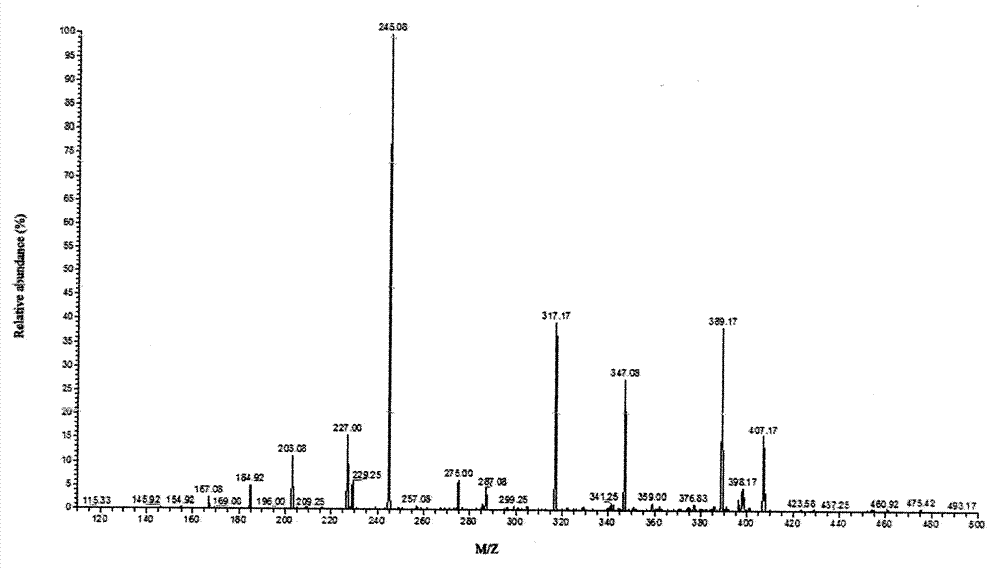

[0059] Embodiment 3: Utilize the method for immobilized fructosyltransferase to catalyze the synthesis of sucrose-6-acetate, with ionic liquid [Dmim][PF6] (99.9%, Shanghai Chengjie Chemical Co., Ltd.) and tert-butanol (anhydrous , Zibo Dehong Chemical Technology Co., Ltd.) mixed solvent as the reaction medium, with sucrose and glucose-6-acetate as the substrate, such as figure 2 shown.

[0060] The reaction system for the synthesis of sucrose-6-acetate catalyzed by immobilized fructosyltransferase is as follows: sucrose (99.5%, Shanghai Bioengineering Co., Ltd.) and glucose-6-acetate (99.9%, Zhengzhou Aoli Industrial Company) Molar ratio 4:1, immobilized fructosyltransferase 40mg / mL, reaction medium ionic liquid [Dmim][PF6] and organic solvent tert-butanol volume ratio 1:1, 5mM phosphate buffer (pH 6.0), 55°C Water bath reaction 20h. Under this condition, the yield of sucrose-6-acetate can reach 57.2g / L, and the yield can reach 86.2%, and the immobilized enzyme can be used ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com