A kind of usage method of blast furnace gas dechlorination agent

A technology for blast furnace gas and dechlorination agent, which is applied in separation methods, chemical instruments and methods, removal of gas pollutants, etc., can solve the problems of high pressure, unsuitable blast furnace gas, large flow rate, etc., and achieves the effect of low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

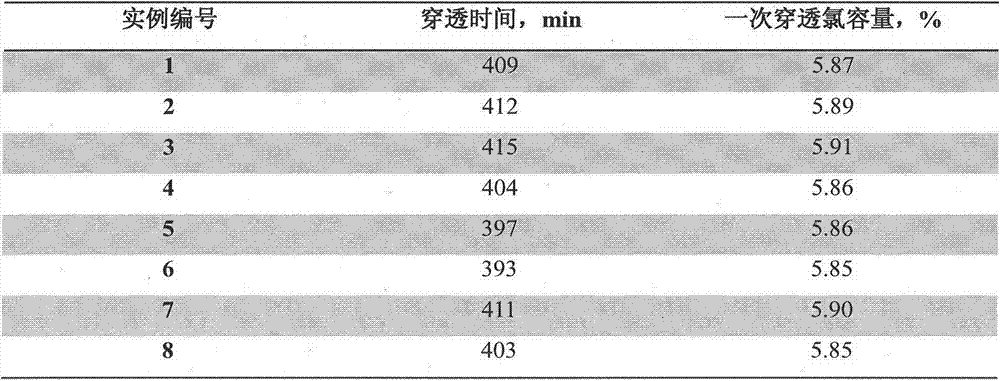

Examples

experiment example 1

[0017] One), select industrial limestone, commercial sodium carbonate and potassium hydroxide as raw material to prepare dechlorination agent, wherein the particle size of limestone is less than 5mm, and the particle size of sodium carbonate and potassium hydroxide is less than 3mm;

[0018] 2), soak the limestone for industrial use as it is in potassium hydroxide solution for 1h, wherein the concentration of potassium hydroxide solution is 10%, and then place the soaked limestone at a high temperature of 700°C for calcination for 1h;

[0019] Three), the calcined limestone (hereinafter referred to as light-burned limestone) and sodium carbonate are ground to below 20 μm with ordinary ball milling process or other milling processes, and then according to light-burned limestone: sodium carbonate=30:70 (weight percentage) Dosing, and then pre-mixing, the mixing time is 10 minutes, and the mixed powder is continued to be ground by the milling process until the particle size of all...

experiment example 2

[0023] One), select industrial limestone, commercial sodium carbonate and potassium hydroxide as raw material to prepare dechlorination agent, wherein the particle size of limestone is less than 5mm, and the particle size of sodium carbonate and potassium hydroxide is less than 3mm;

[0024] Two), the limestone for industrial use is soaked in potassium hydroxide solution for 1 hour as it is, wherein the concentration of potassium hydroxide solution is 15%, and then the soaked limestone is placed in a high temperature conditional calcining at 700° C. for 1 hour;

[0025] Three), the calcined limestone (hereinafter referred to as light-burned limestone) and sodium carbonate are ground to below 20 μm with ordinary ball milling process or other milling processes, and then according to light-burned limestone: sodium carbonate=30:70 (weight percentage) Dosing, and then pre-mixing, the mixing time is 10 minutes, and the mixed powder is continued to be ground by the milling process unt...

experiment example 3

[0029] One), select industrial limestone, commercial sodium carbonate and potassium hydroxide as raw material to prepare dechlorination agent, wherein the particle size of limestone is less than 5mm, and the particle size of sodium carbonate and potassium hydroxide is less than 3mm;

[0030] 2), soak the limestone for industrial use as it is in potassium hydroxide solution for 1h, wherein the concentration of potassium hydroxide solution is 15%, and then place the soaked limestone at a high temperature of 700°C for calcination for 2h;

[0031] Three), the calcined limestone (hereinafter referred to as light-burned limestone) and sodium carbonate are ground to below 20 μm with ordinary ball milling process or other milling processes, and then according to light-burned limestone: sodium carbonate=30:70 (weight percentage) Dosing, and then pre-mixing, the mixing time is 10 minutes, and the mixed powder is continued to be ground by the milling process until the particle size of all...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com