Organic waste recycling method and sterilization apparatus used in method

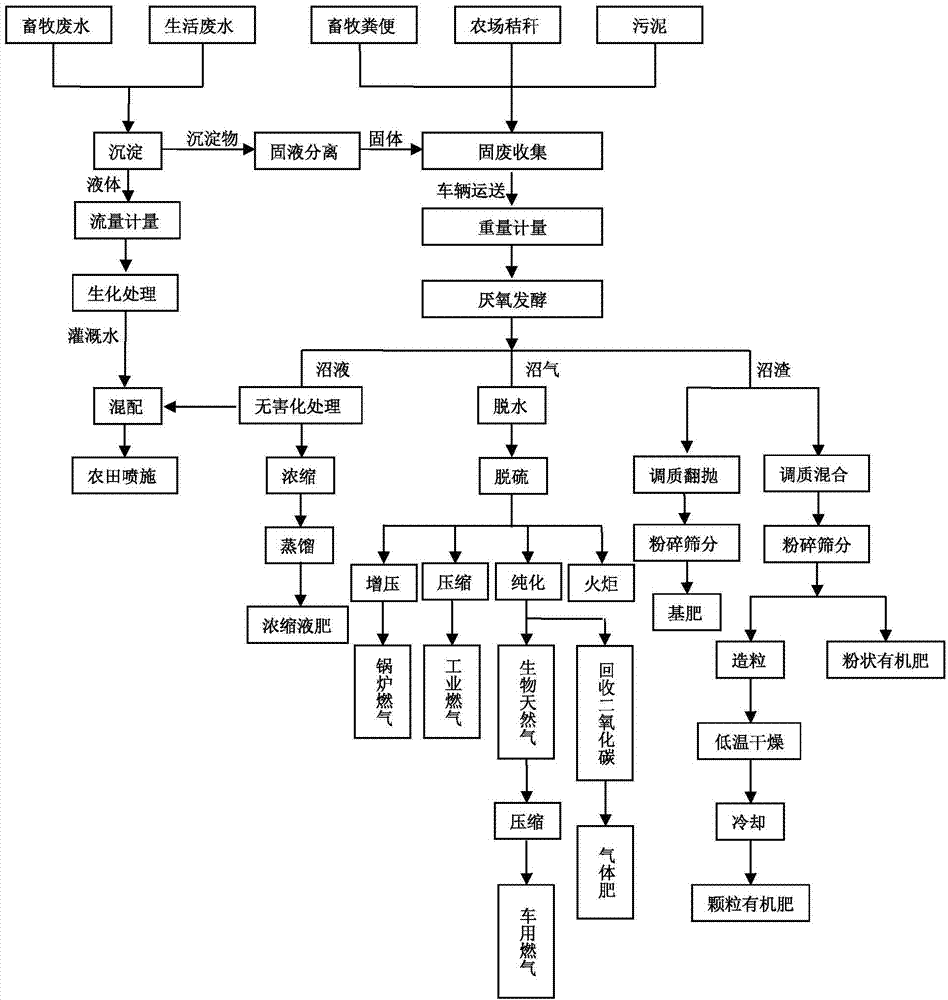

A technology for organic waste and organic wastewater, which is applied in the preparation of organic fertilizers, fertilizers made from biological wastes, organic fertilizers, etc., can solve the problems of secondary pollution, consumption, inability to take into account environmental protection and economic value, etc., and achieve efficient utilization , reduce costs, achieve the effect of environmental and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] 1. Collect domestic wastewater and organic wastewater, enter the sedimentation tank by gravity flow, pump the precipitated and concentrated solid organic waste into the solid-liquid separator, collect the separated solids, and return the separated liquid to the sedimentation tank together with the supernatant After the flow is measured, it is pumped into the anaerobic treatment unit with a lift pump, where the anaerobic treatment unit adopts the anaerobic ammonium oxidation process. The water after anaerobic treatment meets the irrigation water standard, and is mixed with liquid fertilizer according to different soil properties and crop growth periods, and applied to the farmland in an integrated way of water and fertilizer.

[0081] 2. After solid-liquid separation, solids, livestock and poultry pollutants, farmland straw, and kitchen waste are collected and stored in the collection pool. Among them, the farmland straw needs to be crushed, and the kitchen waste needs to...

Embodiment 2

[0093] 1. Collect livestock and poultry breeding wastewater, enter the sedimentation tank by gravity flow, pump the precipitated and concentrated solid organic waste into the solid-liquid separator, collect the separated solids, and return the separated liquid to the sedimentation tank together with the supernatant through After the flow is measured, use a lift pump to pump it into the anaerobic treatment unit. The anaerobic treatment unit here adopts the anaerobic ammonium oxidation process; Mixed with water and fertilizer, etc., and applied to the farmland in an integrated way of water and fertilizer.

[0094] 2. The solids and livestock feces produced after the solid-liquid separation of livestock and poultry breeding wastewater are stored in the collection pool, transported by a screw conveyor, and measured by a weight measuring device, and then the solid content rate is adjusted. The solid content rate reaches 10%. The liquid used in the deployment is reflux biogas slurry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com