Preparation method of graphene

A graphene and pre-reaction technology, applied in the field of graphene, can solve the problems of increased cost, low washing efficiency, low purification efficiency of graphite oxide, etc., and achieves the effects of realizing automatic production, reducing production cost and shortening generation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

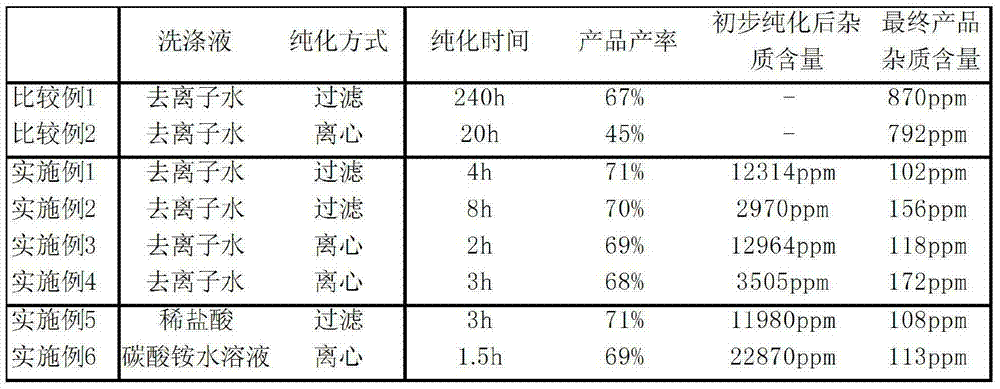

Examples

Embodiment 1

[0032] Embodiment 1, different from Comparative Example 1, this embodiment comprises the following steps:

[0033]Pre-reaction slurry configuration: according to graphite: potassium permanganate: concentrated sulfuric acid (mass concentration is 98%): the mass relation of sodium nitrate=2:5:60:1, in the reactor of 6 ℃, add the vitriol oil (mass Concentration is 98%), sodium nitrate, graphite and potassium permanganate, after being stirred uniformly, pre-reaction slurry is obtained;

[0034] Grafting reaction: put the pre-reaction slurry obtained above in an environment of 6°C for 2 hours, then raise the temperature to 35°C for 30 minutes; then add water to dilute according to the mass relationship of deionized water: concentrated sulfuric acid = 1:2, and complete Afterwards, the temperature was raised to 100°C for 2 hours to obtain graphite oxide grafted with oxidized functional groups;

[0035] Preliminary purification: the product after the above oxidation reaction is washe...

Embodiment 2

[0039] Embodiment 2, different from Embodiment 1, this embodiment includes the following steps:

[0040] Preliminary purification: the product after the above oxidation reaction is washed with deionized water → filtered, and repeated three times. The amount of deionized water used for each washing is half of the mass of concentrated sulfuric acid used in the reactant. Record the total time required for filtering.

[0041] Cleavage: The above-mentioned graphite oxide powder is heated up to 500° C. under a nitrogen atmosphere, and the graphene powder is obtained by cleavage.

[0042] Highly purified: use deionized water to wash and filter the above-mentioned graphene semi-finished product, and repeat twice. The amount of deionized water used for each washing is half the mass of concentrated sulfuric acid used in the reactant, and the total time required for filtration is recorded . After drying, the finished graphene can be obtained.

[0043] Others are the same as in Example...

Embodiment 3

[0044] Embodiment 3, different from Comparative Example 2, this embodiment comprises the following steps:

[0045] Pre-reaction slurry configuration: same as Comparative Example 2.

[0046] Grafting reaction: same as Comparative Example 2.

[0047] Preliminary purification: wash the product after the above oxidation reaction with deionized water → centrifuge → remove the supernatant, and repeat twice, the amount of deionized water used for each washing is half the mass of concentrated sulfuric acid used in the reactant. Record the total time required for centrifugation.

[0048] Cleavage: The above-mentioned graphite oxide powder is heated up to 500° C. under a nitrogen atmosphere, and the graphene powder is obtained by cleavage.

[0049] Highly purified: wash the above semi-finished graphene with deionized water→centrifuge→remove the supernatant, and repeat the operation three times. The amount of deionized water used for each washing is half of the mass of concentrated sul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com