Method for cleaning first mirror for tokamak device by direct-current cascade arc plasma torch

A plasma torch and tokamak technology, applied in the field of magnetic confinement nuclear fusion, can solve problems such as poor cleaning effect, and achieve the effects of simple structure, no impurity directionality, and scientific method steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

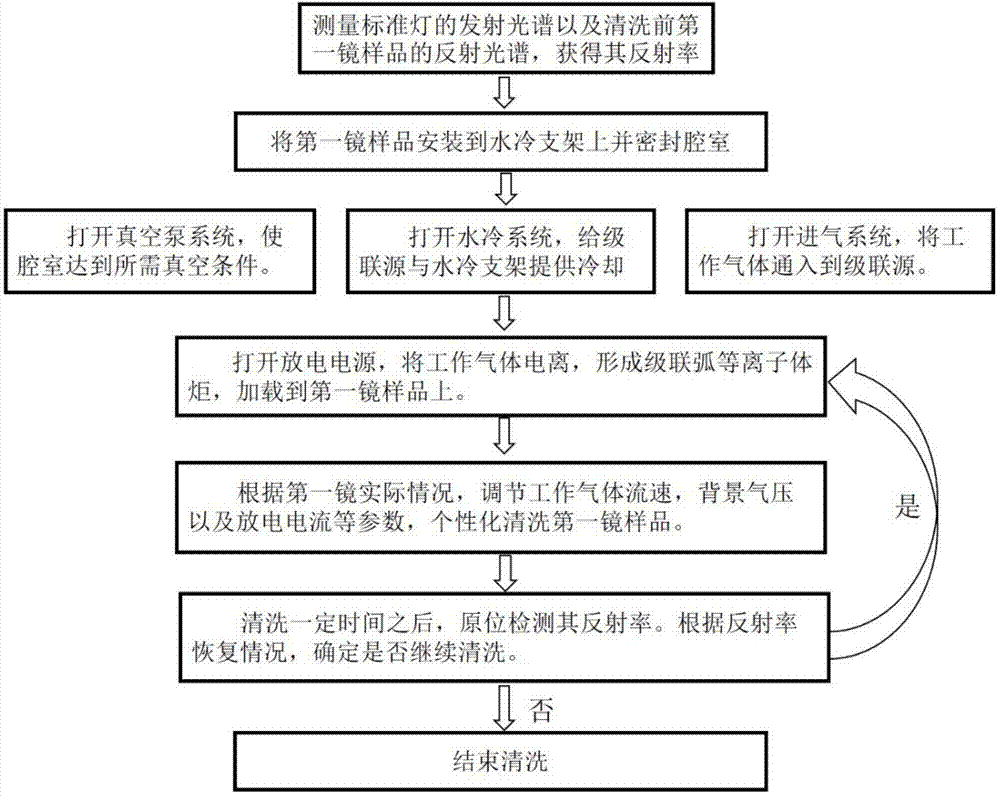

[0029] This embodiment discloses a method for the first mirror of a tokamak based on DC cascaded arc plasma torch technology, which can uniformly and quickly remove the impurity deposition layer on the surface of the first mirror in a large area, and restore the reflectivity of the first mirror , and does not introduce other impurities.

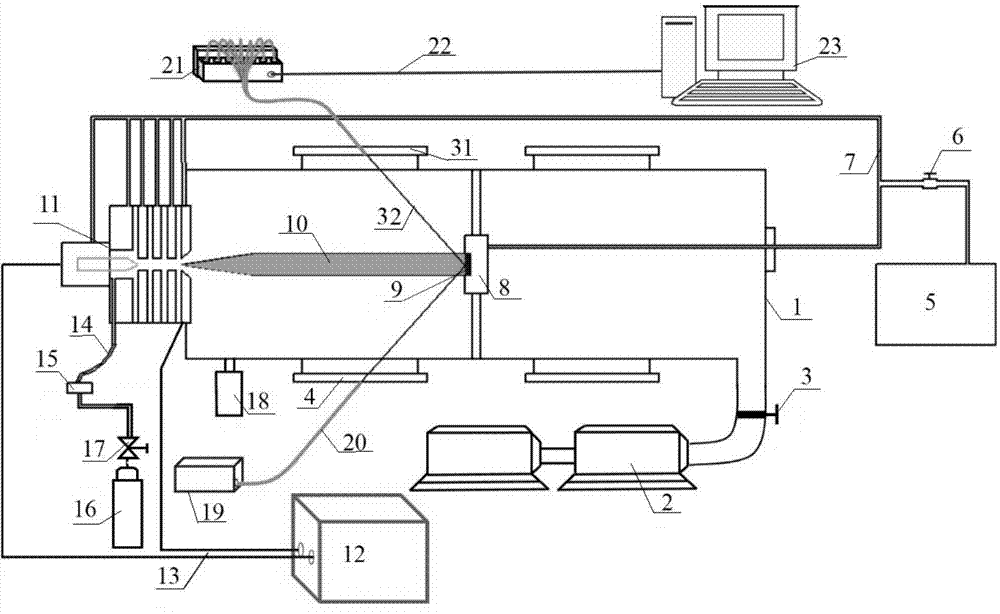

[0030] The device used in the method for cleaning the first mirror of the tokamak with the DC cascade arc plasma torch in this embodiment is as follows: figure 1 As shown, it includes a DC cascade arc plasma torch generation system (taking argon plasma torch as an example), a support system, a cooling water supply system and a reflectivity detection system.

[0031] The cascade arc plasma torch generation system is used to generate a suitable DC cascade arc plasma torch, and the cascade arc plasma torch generation system includes a vacuum chamber 1, a cascade source 11, a DC power supply 12, a vacuum unit , air supply unit and cooling unit. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com