Method used for removing vapour in pyrolysis raw gas, and fixed bed pyrolysis device

A technology of waste gas and water vapor, applied in the field of coal chemical industry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] This embodiment discloses a fixed bed pyrolysis device, which includes pyrolysis reaction tubes and cold traps the same as the existing fixed bed pyrolysis device, and is different from the existing fixed bed pyrolysis device in this Embodiment The fixed-bed pyrolysis device is also provided with a catalytic reactor for eliminating water vapor in the pyrolysis raw coal gas between the pyrolysis reaction tube and the cold trap. Temperature electric heating device.

Embodiment 2

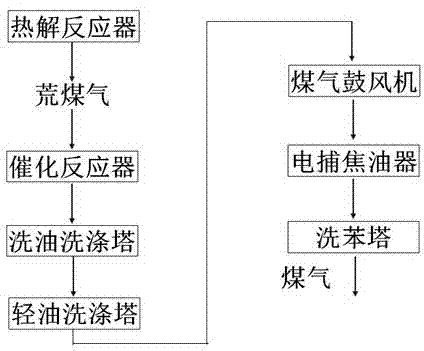

[0039] figure 2 It is the process flow diagram of embodiment 2.

[0040] This embodiment discloses a process flow for pyrolyzing raw gas to eliminate water vapor and recover tar. This process flow is the same as the existing pyrolysis process oil washing process, including a pyrolysis reactor and a washing recovery system. The difference is that in These include catalytic reactors such as figure 2 shown. The raw coal gas produced by the pyrolysis of coal samples is passed into a catalytic reactor equipped with a catalyst. In the catalytic reactor, the water vapor in the raw coal gas and the CO contained in the raw coal gas itself undergo a water-gas shift reaction (CO and water vapor generate The reaction produces CO 2 and hydrogen) to eliminate water vapor, wherein the catalyst is a Co-Mo series sulfur-resistant oil-gas resistant wide-temperature shift catalyst. The raw coal gas after eliminating moisture enters the oil washing tower and light oil washing tower to recov...

Embodiment 3

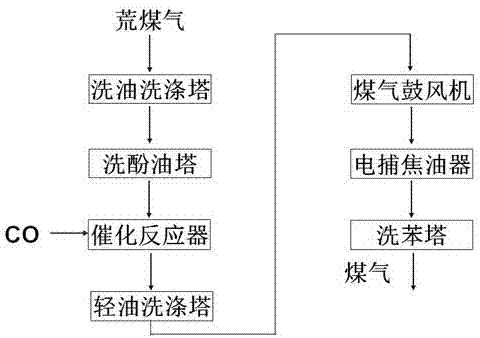

[0042] image 3 It is the process flow diagram of embodiment 3.

[0043] This embodiment discloses a process flow for pyrolyzing raw gas to eliminate water vapor and recover tar. This process flow is the same as the existing pyrolysis process oil washing process, including a pyrolysis reactor and a washing recovery system. The difference is that in These include catalytic reactors such as image 3 shown. The raw coal gas produced by the pyrolysis of coal samples is passed into the oil washing tower and the phenol washing tower to recover part of the tar and phenol oil, and then the raw coal gas containing part of the tar is passed into the catalytic reactor equipped with a catalyst. In the catalytic reactor, The water vapor in the raw coal gas undergoes a water-gas shift reaction with the carrier gas CO to eliminate the water vapor, wherein the catalyst is a Co-Mo series sulfur-resistant, oil-gas and wide-temperature shift catalyst. The raw coal gas after moisture removal e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com