Single shred making process suitable for paper-making process reconstituted tobacco manufacturing plant

A technology for reconstituted tobacco leaves and a production plant, which is applied in the field of separate shredding process, can solve the problems of large loss of aroma of reconstituted tobacco leaves, difficulty in shredding by a shredder, and quality changes of the reconstituted tobacco, and achieves uniformity of feeding, high effective utilization rate, The production environment is less dusty and the effect of ensuring quality consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

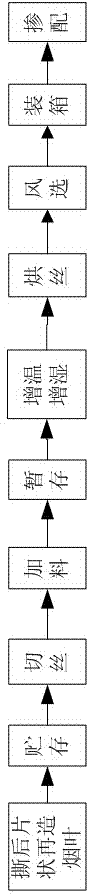

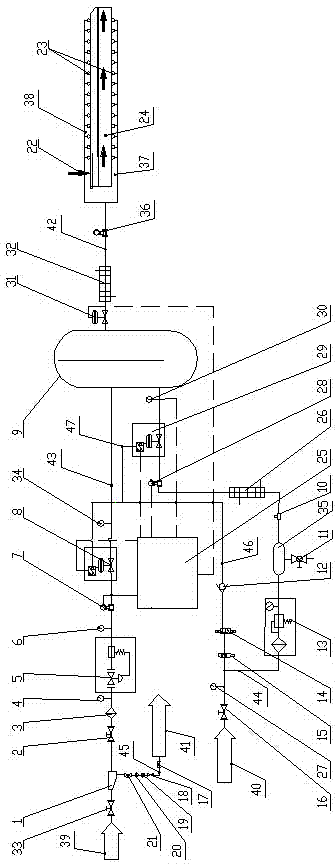

[0046] Such as figure 1 and figure 2 As shown, the individual silk-making process suitable for paper-making reconstituted tobacco leaf production plants includes the following steps:

[0047] (1) Storage: tear the reconstituted cigarette sheet after coating and drying to a moisture content of 14% to 19%, and send it to a storage cabinet for moisture balance and buffering;

[0048] (2) Shred: use a professional shredding machine adapted to the characteristics of reconstituted tobacco leaves to cut thin slices into 0.7-1.1mm thin slices;

[0049] (3) Feeding: After cutting, the flakes enter the feeding machine through the flow control system to apply the feed liquid. Taking advantage of the characteristics of the flakes such as loose structure, large surface area, and fast absorption rate, the cold feeding process is adopted, and HT or hot air is not used for reconstituted tobacco. Heating, feeding at room temperature, the feeding medium can be steam or compressed air, on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com