A hydraulic reaming circular drilling rig and its construction technology for reaming piles

A technology of reaming piles and reaming bits, which is applied in the directions of rotary drilling rigs, drill bits, drill pipes, etc., achieves the effects of high construction efficiency, strong reaming ability and stable reaming effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described in further detail below in conjunction with the embodiments of the drawings.

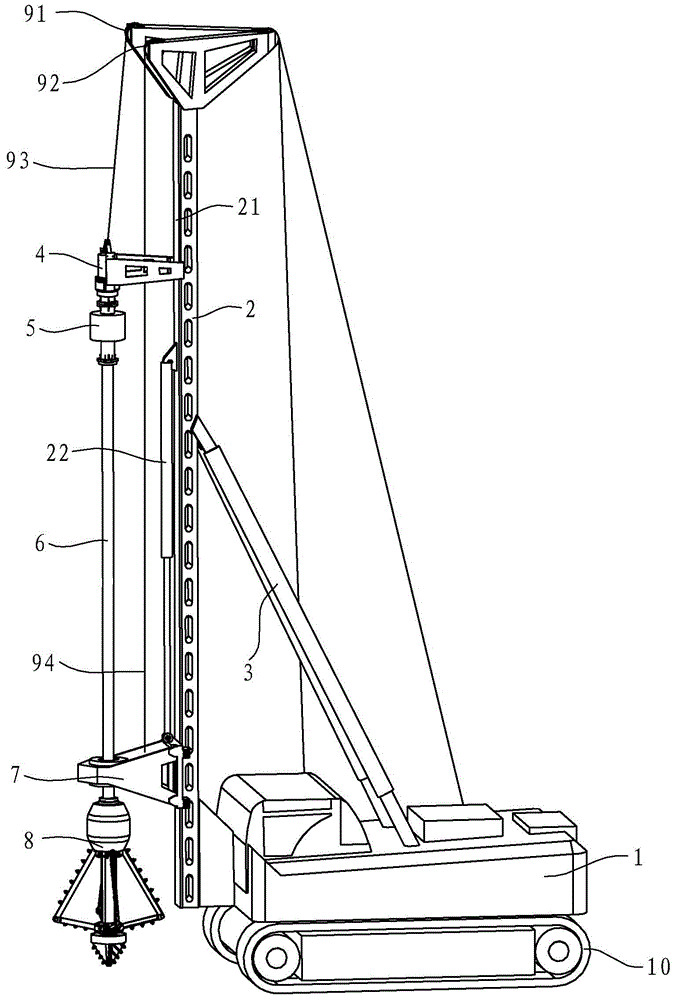

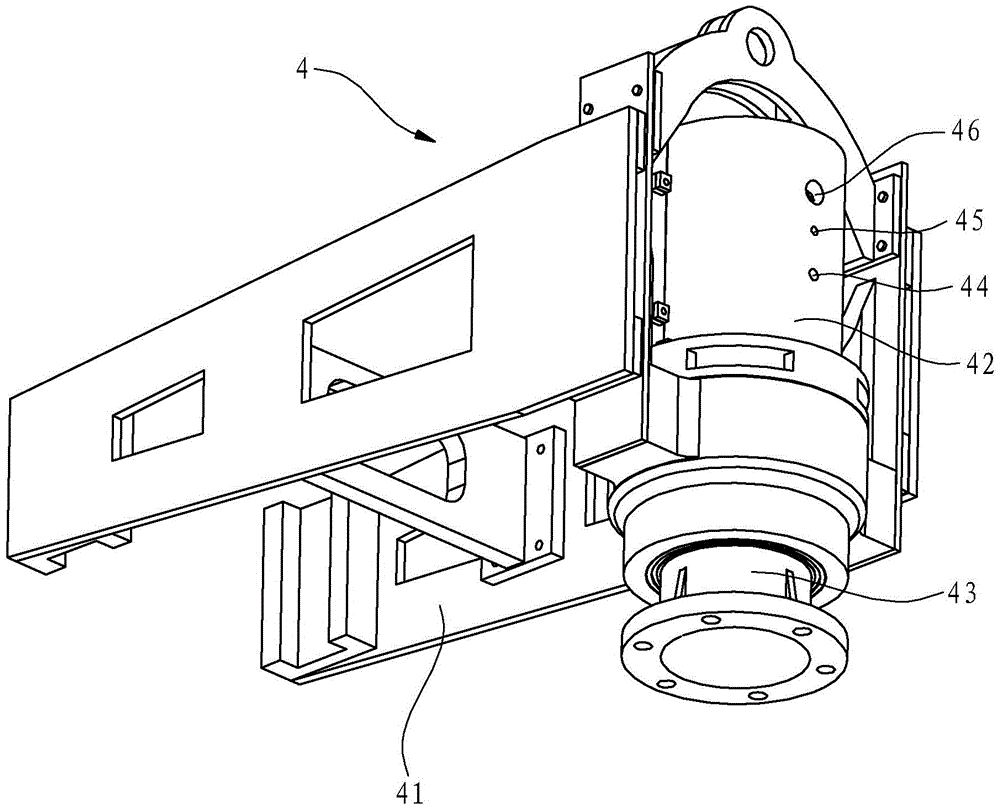

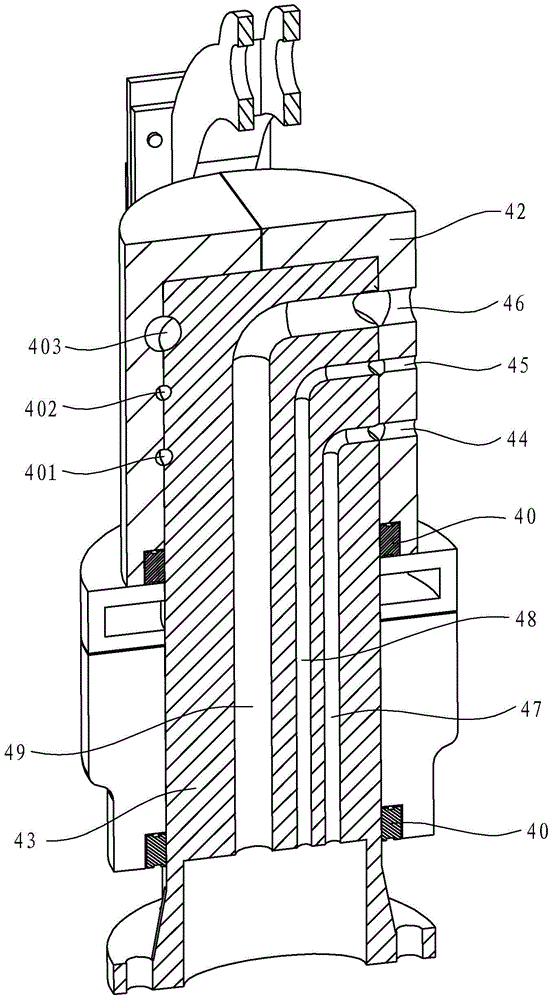

[0047] Such as figure 1 As shown, the hydraulic reaming circulation drilling rig (HRCR drilling rig) in this embodiment includes a pile machine body 1, a mast 2, a mast support mechanism 3, a faucet 4, a hydraulic device 5, a drill rod, a power head 7, and a reaming drill 8. Main components such as pulley block, lifting rope, crawler chassis 10. The HRCR drilling rig is equipped with a visual control system, which can display real-time reaming depth, reaming diameter, reaming cylinder stroke, power head rotation speed; dynamic display of the reaming process; monitoring the current of each motor of the rig, high mechanical automation, reducing labor demand And effectively reduce the probability of safety accidents.

[0048] Among them, the crawler chassis 10 is installed on the bottom of the pile driver body 1, the mast 2 and the mast support mechanism 3 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com