Anti-aging equipment and method for a batch asphalt mixing plant

An asphalt mixture and anti-aging technology, which is applied in roads, road repairs, roads, etc., can solve the problems of adverse impact on asphalt mixture road performance, difficult mixing temperature, and increased cost, so as to improve the adhesion and mixing The uniformity of mixing, the effect of high mixing temperature and long mixing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

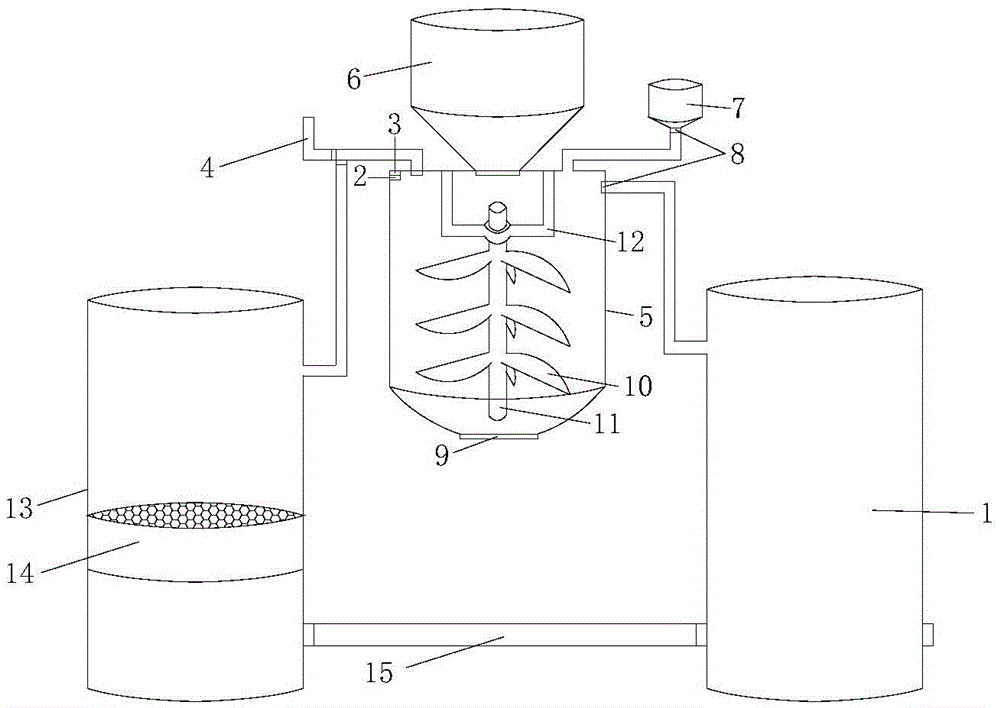

[0023] The present invention is described in further detail below in conjunction with accompanying drawing:

[0024] Such as figure 1 The anti-aging equipment of an intermittent asphalt mixing plant includes an inert gas storage device 1, an inert gas recovery device 13, an oxygen content monitoring device 2, an air pressure monitoring device 3, an exhaust decompression device 4, and an agitator 5. An oxygen content monitoring device 2 and an air pressure monitoring device 3 are installed on the inner top surface of the agitator 5, and the agitator 5 is externally connected with an ore weighing device 6, an asphalt weighing device 7, an inert gas storage device 1, an inert gas Recovery device 13 and exhaust decompression device 4; ore weighing device 6, asphalt weighing device 7, inert gas storage device 1, inert gas recovery device 13, exhaust decompression device 4 and agitator 5 are all installed There is a valve 8; the agitator 5 is a blade agitator, the blade 10 is fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com