Water-soluble polyimide resin solution, and preparation method thereof

A polyimide resin, water-soluble technology, applied in the field of preparation of water-soluble polyimide resin solution, can solve the problems of a large number of organic solvents, achieve the effect of reducing usage and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

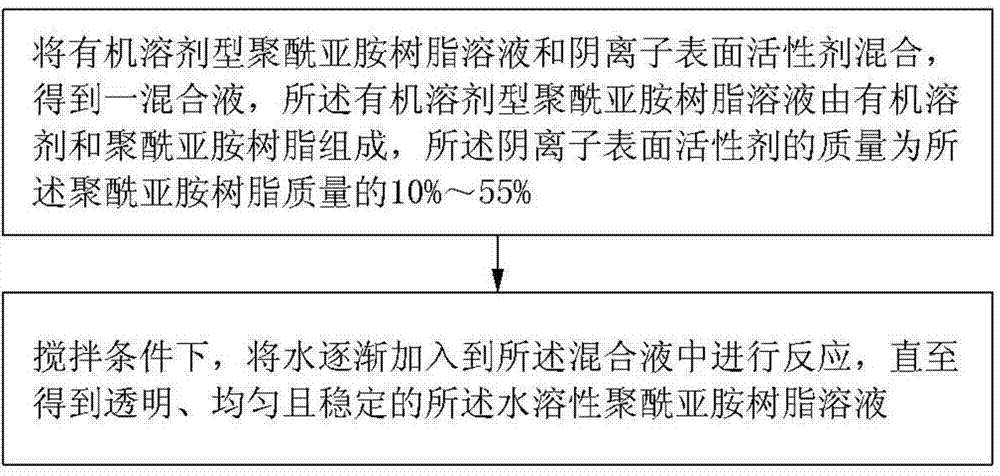

[0023] See figure 2 The embodiment of the present invention further provides a preparation method of the water-soluble polyimide resin solution, including:

[0024] S1, mixing an organic solvent-based polyimide resin solution and an anionic surfactant to obtain a mixed solution, the organic solvent-based polyimide resin solution is composed of an organic solvent and a polyimide resin, and the anionic surface The mass of the active agent is 10%-55% of the mass of the polyimide resin; and

[0025] S2: Under stirring conditions, water is gradually added to the mixed solution for reaction until a transparent, uniform and stable water-soluble polyimide resin solution is obtained.

[0026] In the step S1, the organic solvent-based polyimide resin solution can be directly purchased from the market, or can be configured by itself. For self-preparation, the polyimide resin can be directly dissolved in the organic solvent to obtain the organic solvent polyimide resin solution. The organic ...

Embodiment 1

[0038] Weigh 30 g of an organic solvent polyimide resin solution with a solid content of 10%, the organic solvent is dimethylacetamide, add 3.3 g of sodium dodecylbenzene sulfonate, and stir for 1 hour to make it uniform. Obtain a transparent mixed liquid; add deionized water dropwise while stirring at a temperature of 30°C. The stirring speed is 200r / min. The mass of water added to the mixed liquid per minute is 0.3g. When 120g of water is added, a transparent, Uniform and stable water-soluble polyimide resin solution.

Embodiment 2

[0040] Weigh 30 g of an organic solvent polyimide resin solution with a solid content of 20%, the organic solvent is tetrahydrofuran, add 2.1 g of sodium dodecylbenzene sulfonate, stir for 3.5 hours to make it uniform, and obtain a transparent mixture Liquid; Add deionized water dropwise while stirring at a temperature of 50℃. The stirring speed is 500r / min. The mass of water added to the mixed solution per minute is 0.6g. When 70g of water is added, a transparent, uniform and stable Water-soluble polyimide resin solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com