Suspension buffer dust cover and preparation method thereof

A technology of dust cover and suspension, which is applied in the direction of suspension, cantilever installed on the pivot, transportation and packaging, etc. Low heat resistance, poor ozone resistance and other problems, to achieve good heat aging performance, good elasticity, and small permanent deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

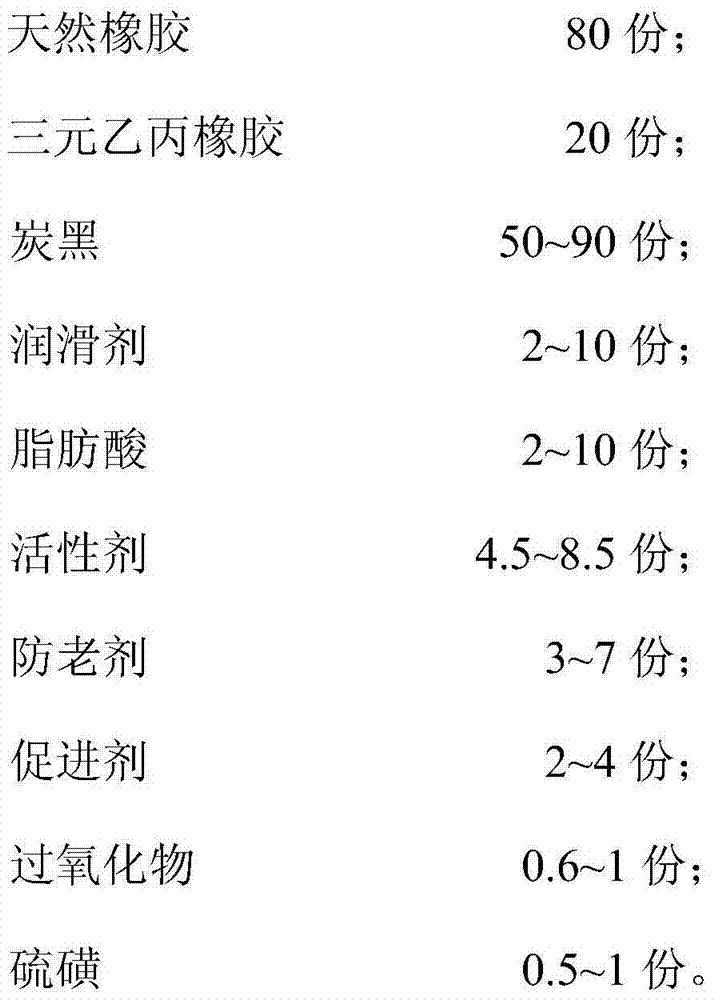

[0040] Embodiment 1: The suspension buffer dustproof cover of this embodiment comprises the following components in parts by weight:

[0041]

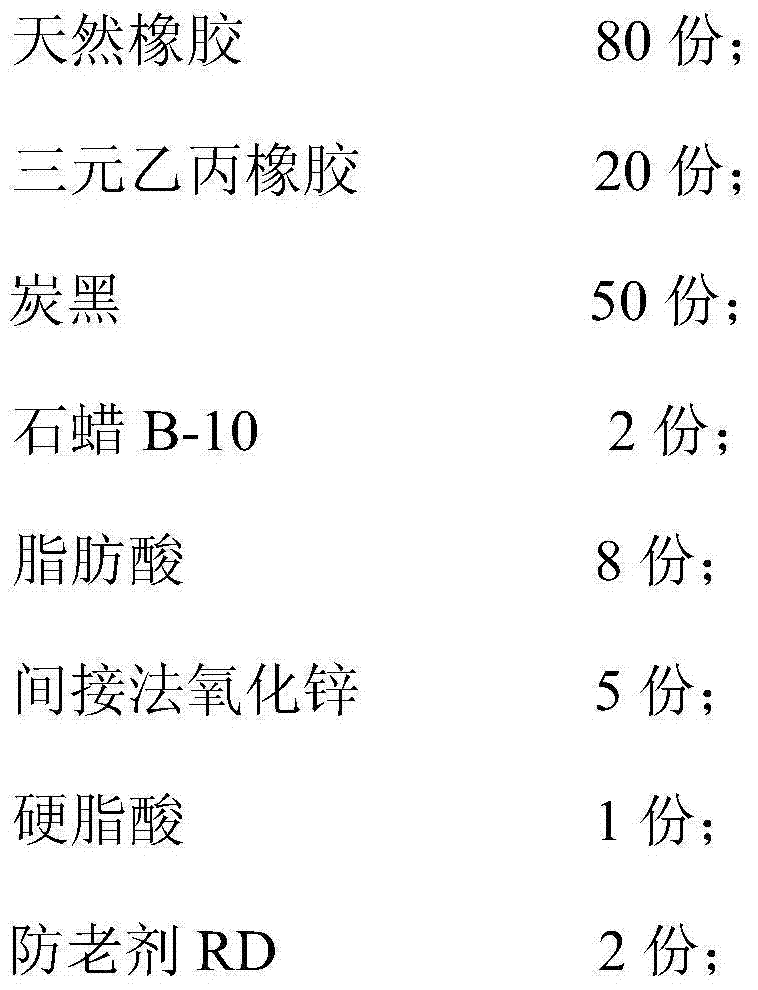

[0042]

[0043] The preparation method of the suspension buffer dustproof cover of the present embodiment comprises the following steps:

[0044] (1) By weight, 100 parts of natural rubber, 50 parts of carbon black N330, 2 parts of paraffin wax B-10, 8 parts of fatty acid, 5 parts of indirect method zinc oxide, 1 part of stearic acid, 2 parts of anti-aging agent RD, anti-aging 2.5 parts of agent 4020, 1 part of accelerator DTDM, 1 part of accelerator CZ, 0.5 parts of insoluble sulfur IS-60, 5 parts of rhine plastic, 0.5 parts of anti-scorch agent CTP, and 0.8 parts of anti-sulfurizing reducing agent SR534D. Mixing, mixing 30min, obtained natural rubber masterbatch;

[0045] 100 parts of EPDM rubber, 50 parts of carbon black N330, 2 parts of paraffin wax B-10, 8 parts of fatty acid, 5 parts of indirect zinc oxide, 1 part of stear...

Embodiment 2

[0049] Embodiment 2: The suspension buffer dustproof cover of this embodiment comprises the following components in parts by weight:

[0050]

[0051] In this embodiment, the preparation method of the suspension buffer dustproof cover is the same as that in Embodiment 1.

Embodiment 3

[0052] Embodiment 3: The suspension buffer dustproof cover of this embodiment comprises the following components in parts by weight:

[0053]

[0054]

[0055] In this embodiment, the preparation method of the suspension buffer dustproof cover is the same as that in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com