Method for synthesizing galactose block copolymer employing RAFT (reversible addition fragmentation chain transfer) method

A technology of block copolymer and galactose, applied in the field of preparation of galactose copolymer, can solve the problems of uncontrollable reaction, free radical termination reaction, etc., and achieve the effects of strong selectivity, low dispersion width and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

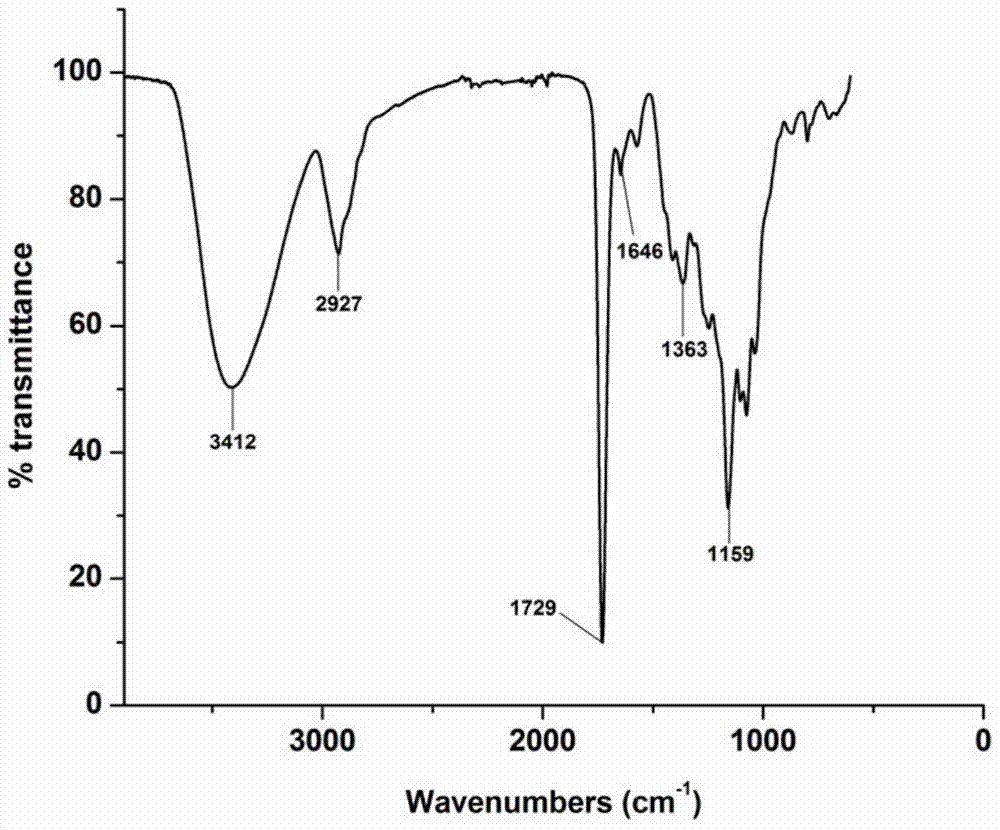

Image

Examples

Embodiment 1

[0028] (1) Dissolve divinyl adipate and galactose at a molar ratio of 3:1 in 100 mL of anhydrous pyridine, add 0.5 g of alkaline protease, and react in a constant temperature water bath at 50 ° C and 200 rpm for 4 days to synthesize vinyl hexyl Diacid galactosyl ester (OVAG).

[0029] (2) Dissolve diethylene glycol dimethacrylate (DEGMA) in 2 mL of DMF, add AIBN as an initiator, and add a chain transfer agent at a molar ratio of 100:1:0.2, and react for 1 h at 70°C under nitrogen protection in an oil bath , placed in an ice-water bath to terminate the reaction, and dichloromethane was used to dissolve the n-hexane precipitate, and this was repeated 3 times to obtain PDEGMA after purification.

[0030] (3) Dissolve vinyl adipate galactose (OVAG) in 2mL DMF, add AIBN as an initiator, add chain transfer agent (polyethylene glycol dimethacrylate PDEGMA), its OVAG, PDEGMA, initiator The molar ratio of 63:1:0.21 was reacted under the protection of nitrogen in an oil bath at 70°C fo...

Embodiment 2

[0032] (1) Dissolve divinyl adipate and galactose at a molar ratio of 3:1 in 100 mL of anhydrous pyridine, add 0.5 g of alkaline protease, and react in a constant temperature water bath at 50 ° C and 200 rpm for 4 days to synthesize vinyl hexyl Diacid galactosyl ester (OVAG).

[0033] (2) Dissolve diethylene glycol dimethacrylate (DEGMA) in 2 mL of DMF, add AIBN as an initiator, and add a chain transfer agent at a molar ratio of 100:1:0.2, and react for 1 h at 70°C under nitrogen protection in an oil bath , placed in an ice-water bath to terminate the reaction, and dichloromethane was used to dissolve the n-hexane precipitate, and this was repeated 3 times to obtain PDEGMA after purification.

[0034] (3) Dissolve vinyl adipate galactose (OVAG) in 2mL DMF, add AIBN as an initiator, add chain transfer agent (polyethylene glycol dimethacrylate PDEGMA), its OVAG, PDEGMA, initiator The molar ratio of 80:1:0.4 was reacted under the protection of nitrogen in an oil bath at 70°C for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com