Method for recycling copper minerals from high-sulfur rebellious copper ore step by step

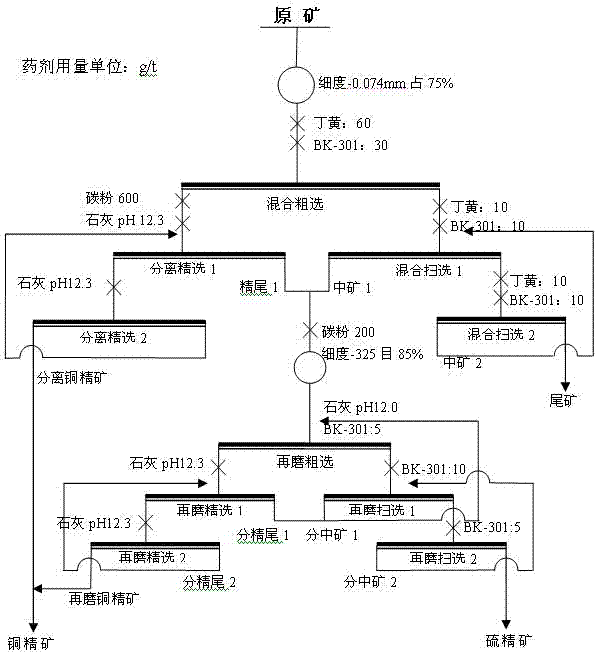

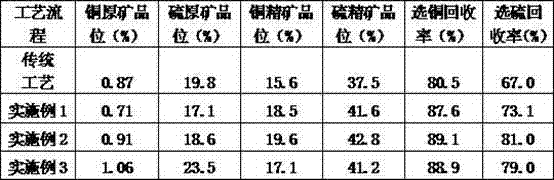

A technology for copper ore and copper recovery, which is used in the step-by-step recovery of copper minerals, the flotation of high-sulfur refractory copper ore, the regrinding and re-election of medium ore, and the mixed flotation of complex high-sulfur refractory copper ore. It can solve the problems that copper minerals cannot be dissociated individually, the recovery rate of copper minerals is not high, and the separation of copper and sulfur is affected, so as to achieve the effect of saving beneficiation costs, easy operation and good recovery.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0036] Example 2: (1), crushing and grinding: the raw ore is crushed and ground, and the particle size of -0.074mm accounts for 73%;

[0037] (2) Mixing and roughing: Send the broken ore after grinding into the flotation machine, add water to adjust the slurry concentration to 33%, add 80g / t butyl xanthate and 40g / t BK-301 and stir for 2.5min, Carry out flotation for 7 minutes to obtain copper and sulfur mixed concentrate and mixed roughing tailings;

[0038] (3) Mixed sweeping 1: add 10g / t butyl xanthate and 20g / t BK-301 to the mixed roughing tailings, stir for 3 minutes and send it to the flotation machine for 7 minutes to obtain middle ore 1 and mixed Sweeping 1 tailings;

[0039] (4) Mixed scavenging 2: add 10g / t butyl xanthate and 10g / t BK-301 to the tailings of mixed scavenging 1, stir for 3 minutes and send it to the flotation machine for 6 minutes to obtain middle ore 2 and Tailings, medium ore 2 returns to mixed sweeping 1, and tailings are discarded;

[0040] (5) ...

Embodiment 3

[0048] Example 3: (1), crushing and grinding: the raw ore is crushed and ground, wherein the particle size of -0.074mm accounts for 75%;

[0049] (2) Mixed roughing: add water to the crushed raw ore to adjust the concentration of the flotation pulp to 35%, add 100g / t butyl xanthate and 100g / t BK-301, stir for 3 minutes and float for 8 minutes to obtain copper , sulfur mixed concentrate and mixed rougher tailings;

[0050] (3) Mixed sweeping 1: Add 30g / t butyl xanthate and 30g / t BK-301 to the mixed roughing tailings, stir for 4 minutes and send it to the flotation machine for 8 minutes to obtain middle ore 1 and mixed Sweeping 1 tailings;

[0051] (4) Mixed sweeping 2: Add 15g / t butyl xanthate and 15g / t BK-301 to the tailings of mixed sweeping 1, stir for 4 minutes and send it to the flotation machine for 8 minutes to obtain middle ore 2 and Tailings, medium ore 2 returns to mixed sweeping 1, and tailings are discarded;

[0052] (5) Separation and concentration 1: add copper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com