Connector structure, female connector and male connector

A technology of male connector and female connector, which is applied in the direction of connection, fixed connection, contact parts, etc., can solve the problems of reducing the height and narrowing of the connecting part, so as to save the height, suppress the reduction of the retention force, and save the space. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

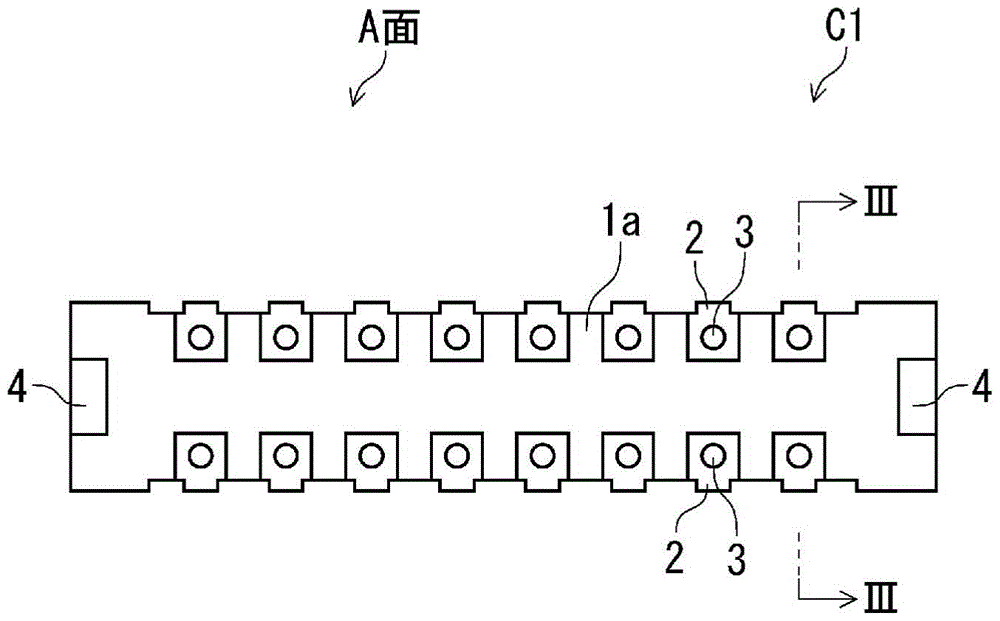

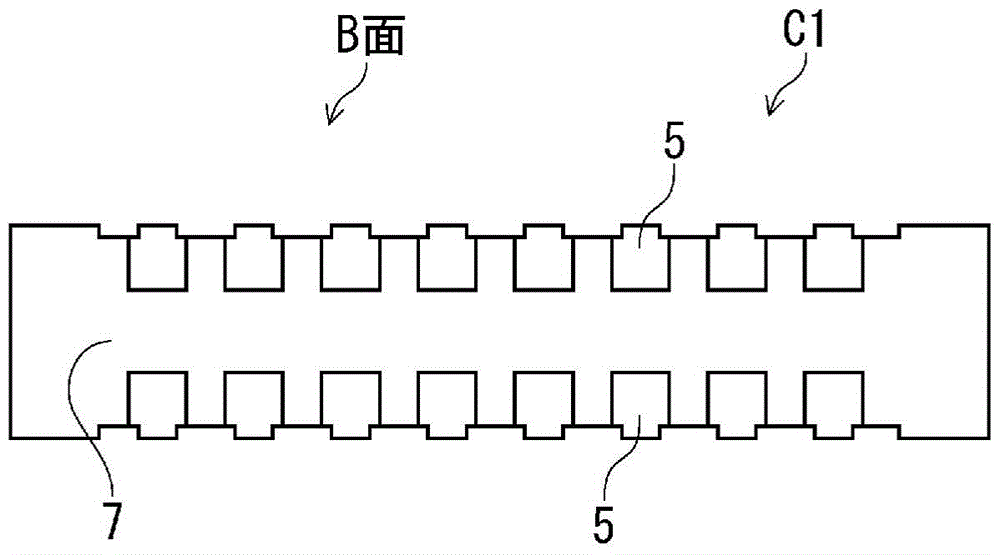

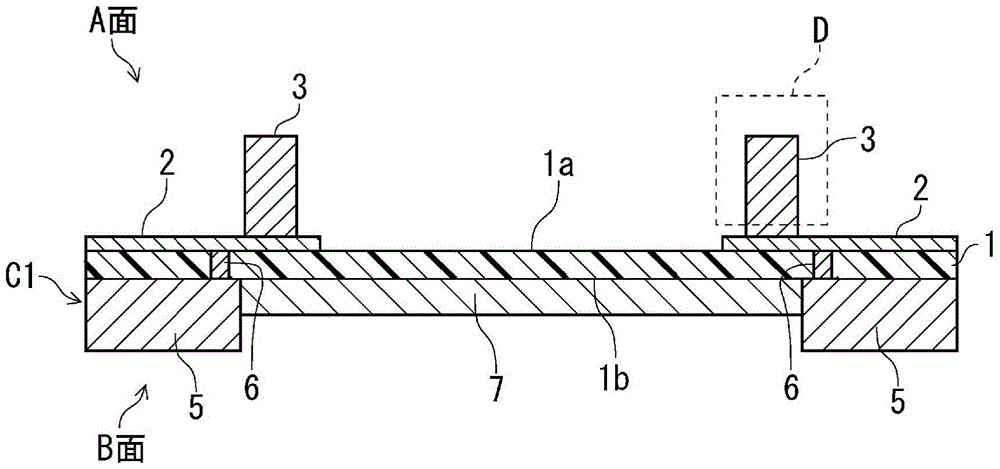

[0061] First, among the male connector and the female connector constituting the connector structure of the present invention, the male connector C1 in which the male terminal portions are arranged in two rows along the longitudinal direction of the connector and the female terminal portions are similarly arranged The basic structure of female connectors C2 in two rows will be described according to the drawings.

[0062] First, the male connector C1 will be described.

[0063] figure 1 It is a plan view showing an example of one surface (hereinafter referred to as A surface) formed by projecting the male terminal portion in the male connector C1; figure 2 is a plan view showing an example of the other side of the male connector C1 (hereinafter referred to as the B side); image 3 is along figure 1 Sectional view of line III-III. Here, the surface B is the back surface of the male connector C1, and this surface is the surface on the mounting side when the male connector C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com