Exploitation method and injection system for oil reservoir of super heavy oil

A production method and technology for super-heavy oil, which are applied in the fields of production of fluids, earth-moving drilling, wellbore/well components, etc., can solve the problems of heat waste, reduced economic benefits, slow oil drainage, etc., to reduce dehydration costs, heat The effect of improved utilization and improved thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

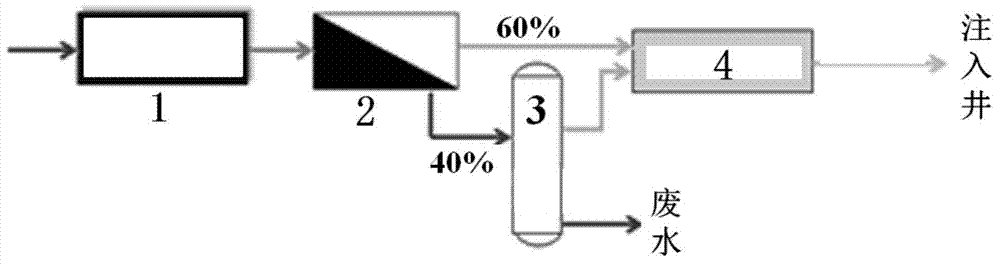

[0067] This embodiment provides an injection system used in the production method of super heavy oil reservoirs, the injection system includes: a solvent injection device, a superheated steam injection device and a non-condensable gas injection device;

[0068] The schematic diagram of the superheated steam injection device is as follows: image 3 As shown, the structural schematic diagram of the non-condensable gas injection device is shown in Figure 4 shown;

[0069] The solvent injection device, the superheated steam injection device and the non-condensable gas injection device are respectively connected with the injection well;

[0070] The solvent injection unit includes in-situ upgrading equipment for hydrogen cracking;

[0071] The superheated steam injection device includes sewage treatment station 1, membrane treatment equipment 2, MVC water treatment station 3 and steam drum boiler 4, sewage treatment station 1, membrane treatment equipment 2 and steam drum boiler...

Embodiment 2

[0082] This embodiment provides a method for producing super heavy oil reservoirs, which is completed through the injection system of Embodiment 1. The buried depth of the reservoir is 600-810m, the oil saturation is 60%, the thickness of the oil layer is 70m, and the horizontal Permeability 1.92μm 2 , the vertical to horizontal permeability ratio is 0.56, the porosity is 27%, there is no continuous distribution of impermeable mudstone and shale interlayers in the oil layer, and the crude oil viscosity under the oil layer condition is 16.8×10 4 mPa·s, specifically including the following steps:

[0083] The injection-production well pattern is deployed, and the injection-production well pattern composed of vertical wells and horizontal wells is adopted, and the well spacing of the injection-production wells is 35m;

[0084] Simultaneously inject solvent and superheated steam into the injection well through the solvent injection device and superheated steam injection device, w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Buried depth | aaaaa | aaaaa |

| Horizontal permeability | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com