Multifunctional snow collector

A snow harvester, multi-functional technology, applied in snow surface cleaning, construction, cleaning methods, etc., can solve the problems of poor snow harvesting effect, limited snow storage capacity, limited capacity, etc., to achieve a wide range of applications and high snow harvesting efficiency. , the effect of strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

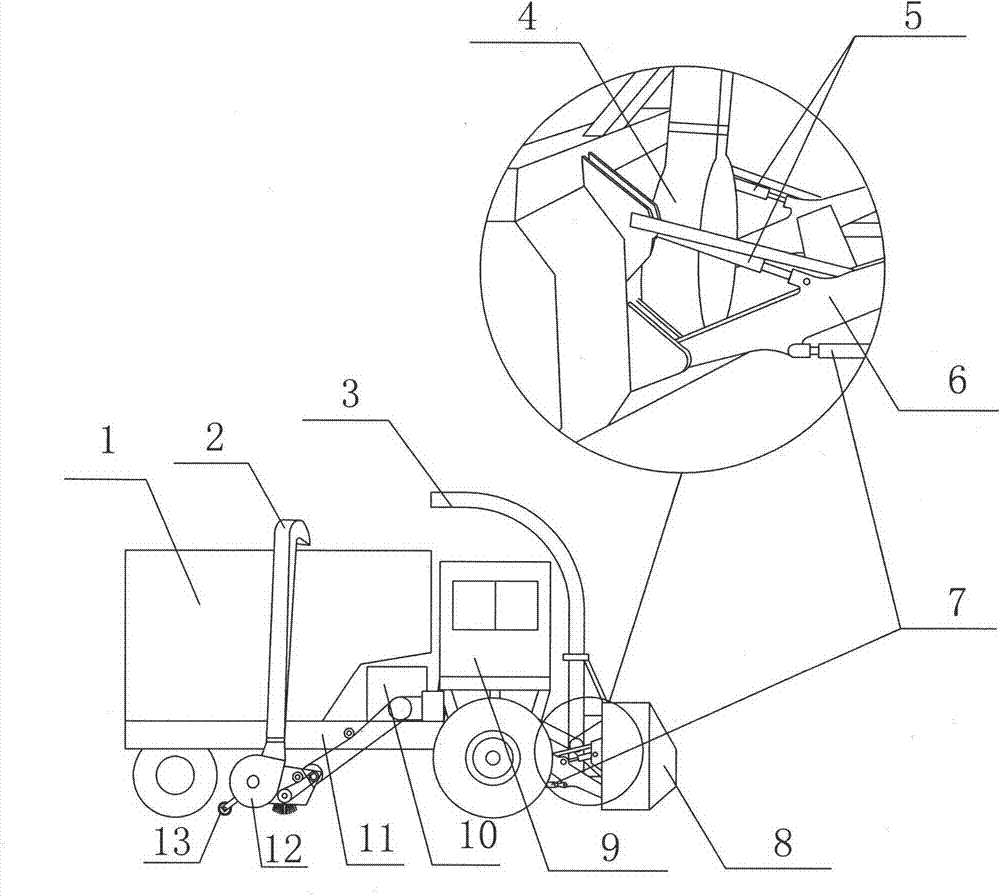

[0031] as attached figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, a kind of multifunctional snow harvester is provided now, comprises car body 11, driver's cab 9, diesel engine 10, compartment 1, and described car body 11 front side is connected with snow plowing mechanism by connecting frame 6, and this snow plowing mechanism comprises Snow collecting shovel 8, conveyor casing 4 arranged on the rear side of snow collecting shovel 8, double impeller 17 installed in conveyor casing 4, upstream conveying pipe 3 arranged on top of conveyor casing 4 and transporting goods to compartment 1 A snow inlet 16 communicating with the snow shovel 8 is opened on the conveyor housing 4, and a forward and reverse auger that can accumulate snow toward the snow inlet 16 is installed horizontally in the snow shovel 8. The reverse auger includes a rotating shaft 15 and two helical blades 14 arranged on the rotating shaft 15. The two helical blades 14 are respectively arran...

Embodiment 2

[0040] as attached figure 1 , figure 2 , Image 6 As shown, the structure of this embodiment is basically the same as that of Embodiment 1, the difference is that the road clearing mechanism includes a snow inlet part and a conveying part, and the snow inlet part consists of a brush roller that stretches out of the road cleaner housing 12 and contacts the ground. 21, and the conveying part is composed of a conveying auger, which includes a through-shaft 22 parallel to the brush roller 21, a spiral conveying blade 23 arranged around the through-shaft 22, and covering the conveying part One side of the road clearing machine casing 12 is provided with a discharge port 30 corresponding to the conveying auger.

[0041] This technical solution realizes that most of the snow on the road is collected into the compartment 1, and the remaining snow is piled up on the roadside, so that the road surface is basically cleaned.

Embodiment 3

[0043] as attached figure 1 , figure 2 , Figure 7 As shown, the structure of this embodiment is basically the same as that of Embodiment 1, except that the snow inlet part is replaced by at least two road clearing discs 26 protruding from the road clearing housing 12 and in contact with the ground, with brushes 20 . The snow inlet part of the structure is similar to the existing road sweeper, and the cleaning effect is ideal.

[0044] In addition, this embodiment can be expanded, that is, two different conveying parts similar to the first and second embodiments are used, and then used in combination with this kind of snow inlet part.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com