A method for producing ethanol from lignocellulose by natural pH fermentation

A technology of lignocellulose and ethanol production, which is applied in the field of microbial fermentation, can solve the problems of complex operation, high content of miscellaneous bacteria, and affecting fermentation yield, and achieve good fermentation performance, high ethanol output, and avoid complex operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

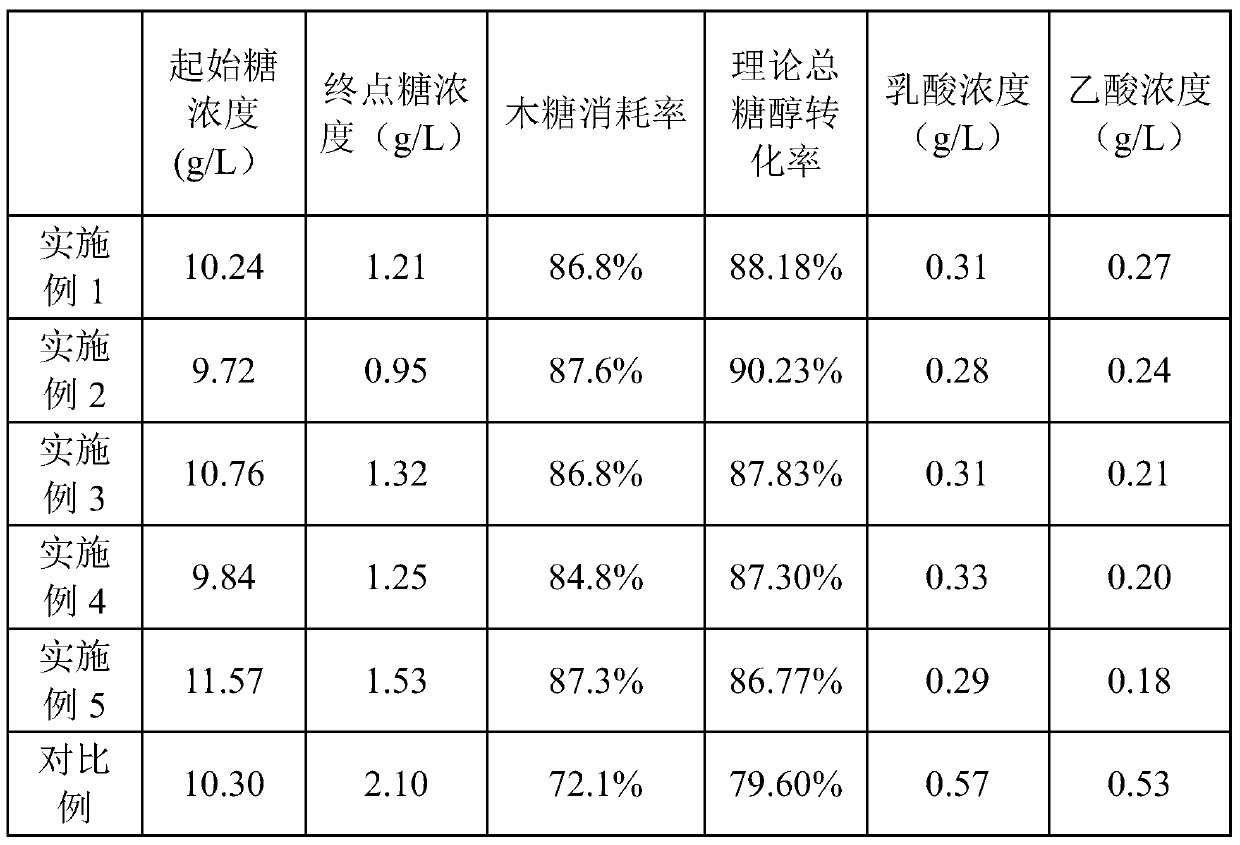

Examples

Embodiment 1

[0034] The method for producing ethanol from lignocellulose at natural pH of the present embodiment comprises the following steps:

[0035] 1) Take the Ho-Purdue yeast 424A (LNH-ST) strain for seed cultivation and expansion cultivation; the cultivation process is as follows:

[0036] Seed culture: 10g / L yeast powder, 20g / L peptone, and 20g / L glucose were mixed and sterilized to prepare a seed liquid medium, and the Ho-Purdue yeast 424A (LNH-ST) strain was inoculated into the The culture medium mentioned above was cultivated for 20 hours until the strain concentration reached (0.2-0.3)×10 9 / ml.

[0037] Expansion cultivation: take the bacteria obtained in the seed cultivation, inoculate 5% of the inoculum into the shake flask containing the expansion culture medium, the expansion temperature is 30°C, the rotation speed is 200rpm, the cultivation time is 16h, and the first-level bacteria are 5 % inoculated into the second-stage expansion culture medium, adjust the pH value to...

Embodiment 2

[0043] The method for producing ethanol from lignocellulose at natural pH of the present embodiment comprises the following steps:

[0044] 1) Take the Ho-Purdue yeast 424A (LNH-ST) strain for seed cultivation and expansion cultivation; the cultivation process is as follows:

[0045] Seed culture: 10g / L yeast powder, 20g / L peptone, and 20g / L glucose were mixed and sterilized to prepare a seed liquid medium, and the Ho-Purdue yeast 424A (LNH-ST) strain was inoculated into the culture medium at 30°C and pH 6.0 until the strain concentration reaches (0.1-0.2)×10 9 / ml.

[0046] Expansion cultivation: take the bacteria obtained in the seed cultivation, inoculate 20% of the inoculum into the shake flask containing the expansion culture medium, adjust the pH value to 4, expand the cultivation temperature at 35°C, rotate at 100rpm, and cultivate for 14 hours. Expand the culture to (0.2-0.3) × 10 9 / ml.

[0047] The medium for the expanded culture is sweet sorghum stalk juice cont...

Embodiment 3

[0052] The method for producing ethanol from lignocellulose at natural pH of the present embodiment comprises the following steps:

[0053] 1) Take the Ho-Purdue yeast 424A (LNH-ST) strain for seed cultivation and expansion cultivation; the cultivation process is as follows:

[0054] Seed culture: 10g / L yeast powder, 20g / L peptone, and 20g / L glucose were mixed and sterilized to prepare a seed liquid medium, and the Ho-Purdue yeast 424A (LNH-ST) strain was inoculated into the The culture medium mentioned above was cultivated until the strain concentration reached (0.4-0.5)×10 9 / ml.

[0055] Expansion cultivation: take the bacteria obtained in the seed cultivation, inoculate 10% of the inoculum into the shake flask containing the expansion culture medium, adjust the pH to 6, expand the cultivation temperature at 28°C, rotate at 150rpm, cultivate for 14 hours, expand Cultivate to (0.2-0.3)×10 9 / ml.

[0056] The culture medium of described expansion is the molasses culture m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com