Bi-component condensed type organic silicon pouring sealant as well as preparation method and application thereof

A silicone potting, condensation-type technology, applied in the directions of non-polymer adhesive additives, adhesives, adhesive additives, etc., can solve the problems of increasing the amount of catalyst used, pores, and insufficient curing depth, so as to meet the waterproof requirements. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

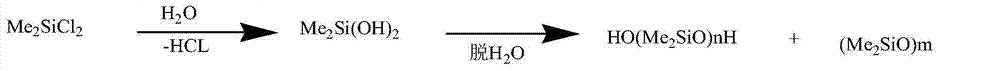

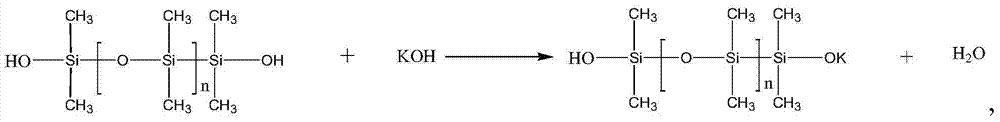

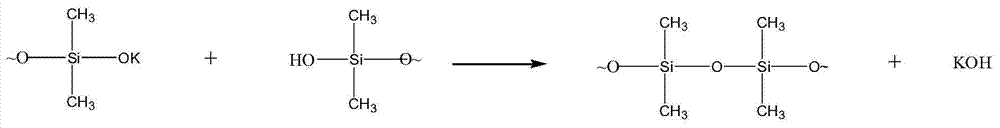

Method used

Image

Examples

Embodiment approach

[0036] One embodiment of the invention includes:

[0037] A two-component condensation type silicone potting compound, including A component and B component;

[0038] The above component A contains the following raw materials in parts by weight: 350-500 parts of linear hydroxyl-terminated polydimethylsiloxane, 300-600 parts of filler, 50-150 parts of base glue, and 0.1-5 parts of deep-layer curing agent;

[0039] The above component B contains the following raw materials in parts by weight: 200-500 parts of crosslinking agent, 300-800 parts of plasticizer, 50-100 parts of coupling agent, and 0.5-2 parts of catalyst;

[0040] The weight ratio of the above-mentioned component A to the above-mentioned component B is 100:5˜100:20.

[0041] The A component and the B component in the above two-component condensation type silicone potting compound undergo a crosslinking reaction at room temperature, vulcanize into a rubber elastic body, and realize the potting function.

[0042] Th...

Embodiment 1

[0083] A glue component:

[0084]

[0085] Add the basic compound, base glue, flame retardant and carbon black into the dispersing tank according to the designed ratio, disperse evenly at high speed, cool to 40-50°C, add deep curing agent, stir evenly at low speed, vacuumize, and then pack.

[0086] B glue components:

[0087]

[0088] Mix the cross-linking agent, coupling agent, catalyst and plasticizer evenly, remove the small molecular compounds, leave it for 24 hours, and then pack it.

Embodiment 2

[0090] A glue component:

[0091]

[0092] Add the basic compound, base glue, thermal conductive powder and carbon black into the dispersion cylinder according to the designed ratio, disperse evenly at high speed, cool to 40-50°C, add deep curing agent, stir evenly at low speed, vacuumize, and then pack.

[0093] B glue components:

[0094]

[0095] Mix the cross-linking agent, coupling agent, catalyst and plasticizer evenly, remove the small molecular compounds, leave it for 24 hours, and then pack it.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com