Method and device for preparing ecological cultivation substrate from urban waste

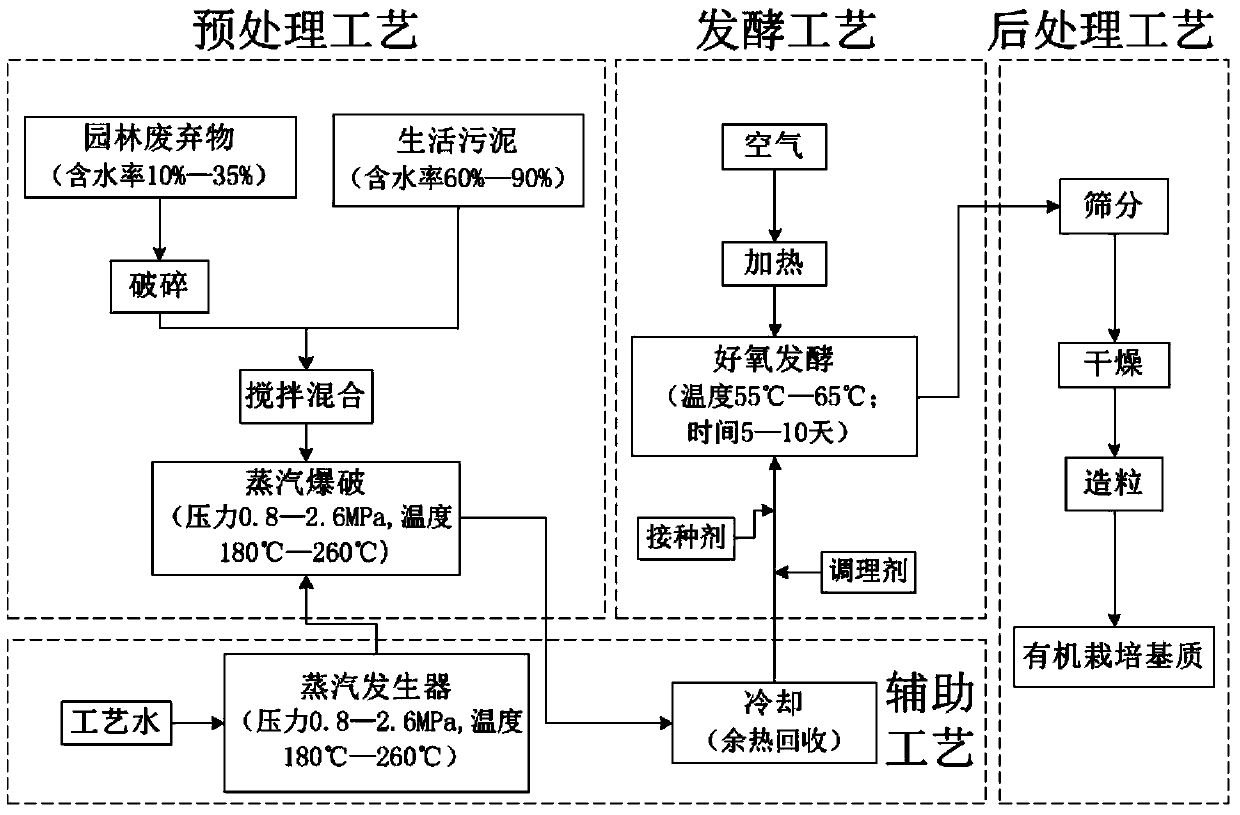

A cultivation substrate and waste technology, which is applied in the field of urban waste recycling and preparation of new ecological cultivation substrates, can solve problems such as environmental pollution and short fermentation cycle, and achieve shortened fermentation time, short required time, and energy saving in the production process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

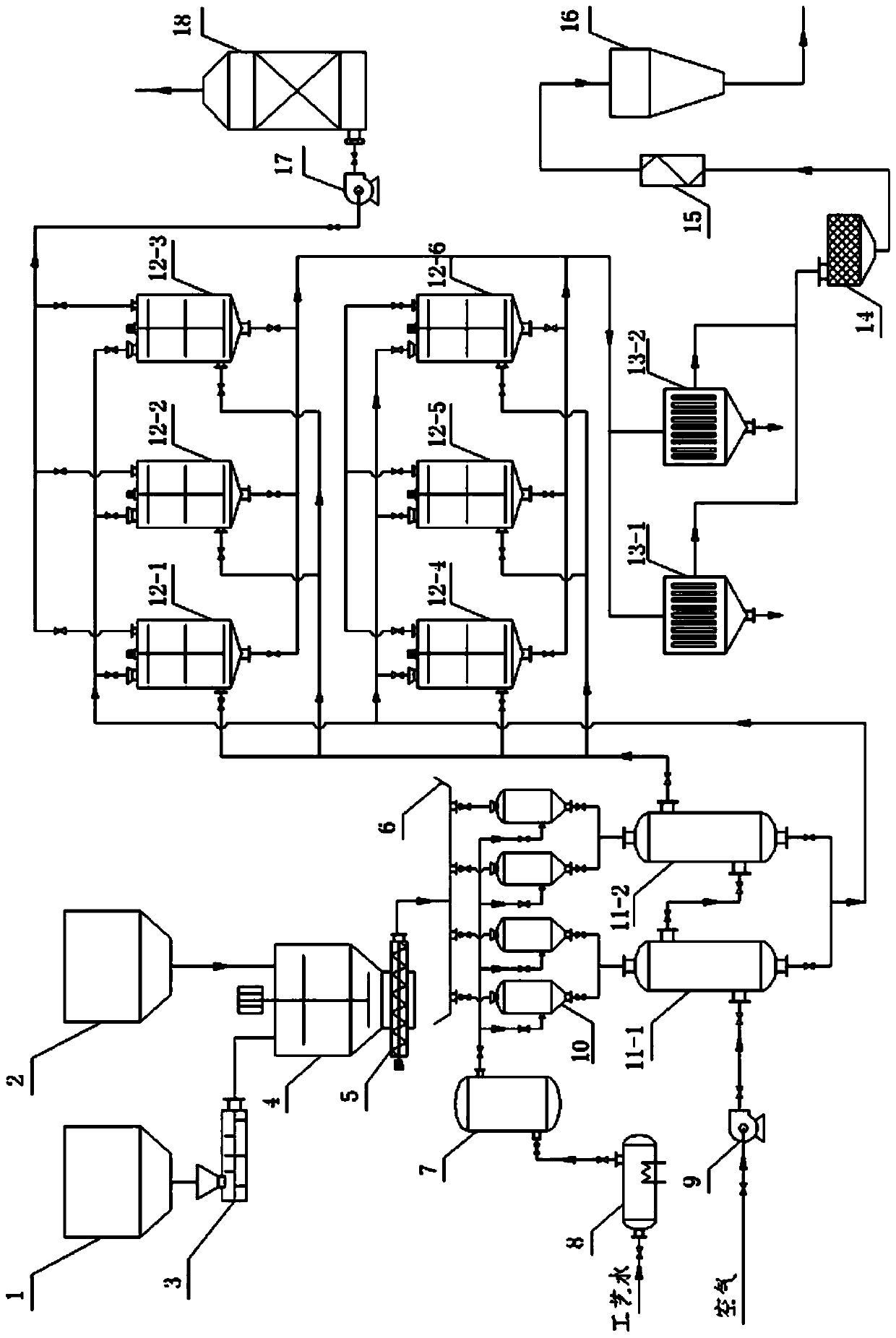

Embodiment 1

[0046] Start the steam generator 8, open the outlet valve of the steam generator 8 and the inlet valve of the steam buffer tank 7. Simultaneously the garden waste that contains the tree branch pruning thing that water content is 10% joins in the garden waste storage tank 1, and the water content of municipal domestic sludge that water content is 96% is reduced to 90% after being dried, and then cut Add to the sludge storage tank 2 after cutting. Open the discharge valve of garden waste storage tank 1, make garden waste enter in the crusher 3, its particle diameter after crushing is 3cm. Open the valves of the crusher 3 and the sludge storage tank 2, transport the material to the mixing tank 4 according to the mass ratio of urban domestic sludge and garden waste mixed at 1:0.3, and mix the mixed material for 5 minutes. Delivered to the distribution trough 6 by the auger conveyor 5.

[0047] The distribution trough 6 distributes materials to each steam explosion tank in turn, ...

Embodiment 2

[0050] Start the steam generator 8, open the outlet valve of the steam generator 8 and the inlet valve of the steam buffer tank 7. At the same time, the garden waste containing plant litter and branch clippings with a moisture content of 15% is added to the garden waste storage tank 1, and the urban domestic sludge with a moisture content of 95% is dried and the moisture content is reduced to 85%. , then join in the sludge storage tank 2 after shearing, open the discharge valve of the garden waste storage tank 1, make the garden waste enter in the crusher 3, its particle diameter after crushing is 2cm. Open the valves of the crusher 3 and the sludge storage tank 2, and make the material enter the mixing tank 4 according to the mass ratio of municipal domestic sludge and garden waste mixed at 1:2. After stirring and mixing for 5 minutes, pass the mixed material through The auger conveyor 5 is delivered to the distribution chute 6.

[0051] The distributing chute 6 distributes ...

Embodiment 3

[0054] Start the steam generator 8, open the outlet valve of the steam generator 8 and the inlet valve of the steam buffer tank 7. At the same time, lawn clippings, weeds, seeds or residual garden wastes with a water content of 35% are added to the garden waste storage tank 1, and the water content of municipal domestic sludge with a water content of 95% is reduced to 60% after being dried. %, add in the sludge storage tank 2 after shearing again, open the discharge valve of the garden waste storage tank 1, make the garden waste enter in the crusher 3, its particle diameter after crushing is 2cm. Open the valve of the crusher 3 and the sludge storage tank 2, and make the material enter the mixing tank 4 according to the mass ratio of urban domestic sludge and garden waste mixed at 1:0.8, and after mixing for 5 minutes, pass the mixed material through The auger conveyor 5 is delivered to the distribution chute 6.

[0055]The distributing chute 6 distributes materials to each s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com