A method for preparing mechanically sensitive glass by isothermal two-step ion exchange

A technology of ion exchange and mechanics, which is applied in the field of material engineering, can solve the problems of high requirements for molten salt "freshness", insufficient glass compressive stress, insufficient stress thickness, etc., achieve good performance, avoid the influence of glass strength, Good fracture concentration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

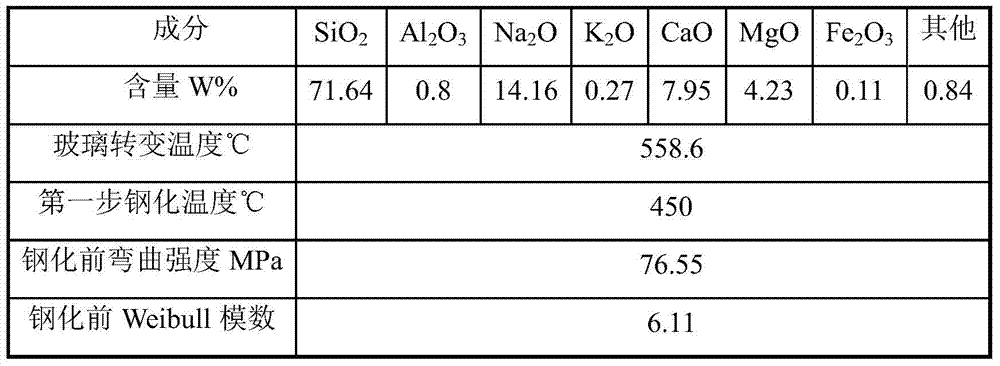

[0037] Its components and properties of the selected soda-lime-silica glass in the present embodiment are as shown in Table 1:

[0038] Table 1

[0039]

[0040] This example provides an ion exchange medium for preparing mechanically sensitive glass, which can be used as the first step of preparing mechanically sensitive glass to temper molten salt for ion exchange, and the contents of its components are shown in Table 2.

[0041] Table 2

[0042] molten salt components

diatomite

clay

Ceria

total

purity

≥99.8%

≥99%

≥99.8%

≥99.8%

≥99%

≥99%

≥99.8

96%

0.6%

1.5%

0.2%

1%

0.5%

0.2%

100%

[0043] This embodiment also provides an ion exchange medium for preparing mechanically sensitive glass, which can be used as the second step of tempering molten salt for preparing mechanic...

Embodiment 2

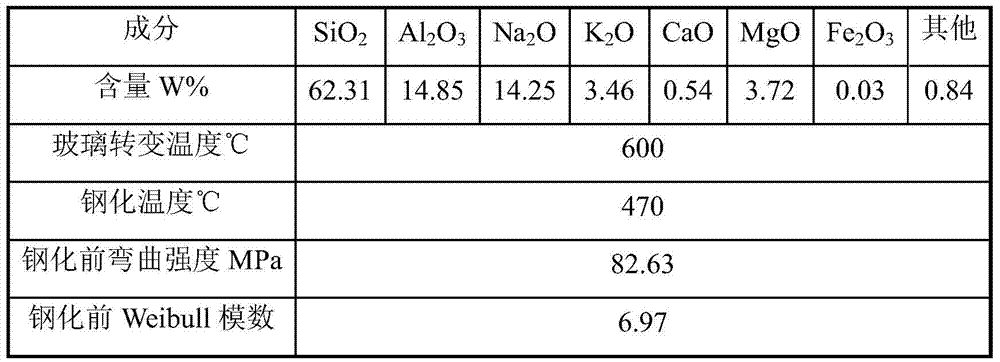

[0055] Its components and properties of the selected sodium aluminum silicate glass in the present embodiment are as shown in Table 4:

[0056] Table 4

[0057]

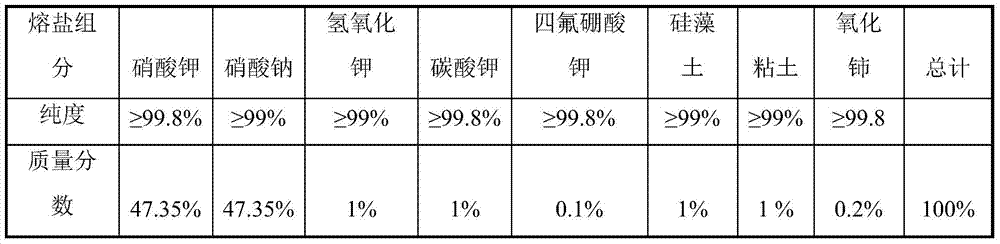

[0058] This example provides an ion exchange medium for preparing mechanically sensitive glass, which can be used as the first step of preparing mechanically sensitive glass for ion exchange by tempering molten salt, and the contents of its components are shown in Table 5.

[0059] table 5

[0060] molten salt components

Potassium tetrafluoroborate

diatomite

clay

Ceria

total

purity

≥99.8%

≥99%

≥99.8%

≥99.8%

≥99%

≥99%

≥99.8

95.7%

1%

1%

0.1%

1%

1%

0.2%

100%

[0061] This embodiment also provides an ion exchange medium for preparing mechanically sensitive glass, which can be used as the second step of tempering molten salt for preparing m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| compressive stress | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com