Method for preparing nano bismuth oxide by using liquid phase precipitation method

A technology of nano-bismuth oxide and liquid phase precipitation, which is applied in the field of nano-materials, can solve the problems of long reaction cycle and high energy consumption, and achieve the effects of good shape, low preparation cost and easy control of operating conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

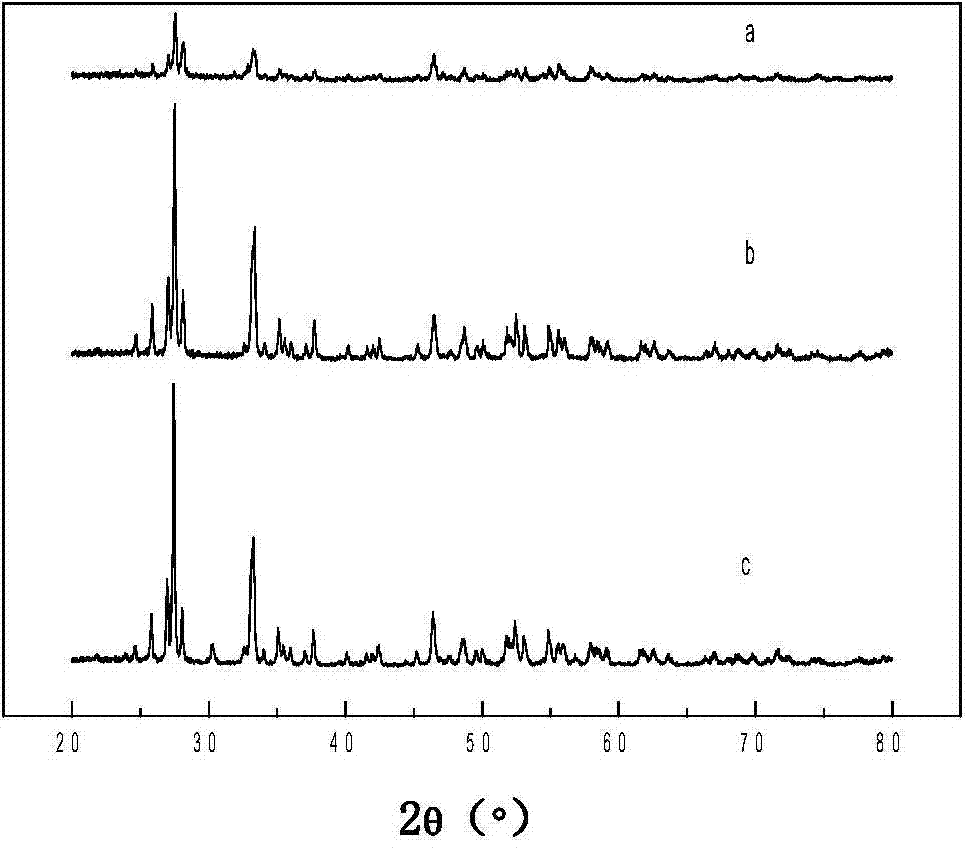

[0023] Take 14g NaOH in a beaker, add 175mL deionized water and stir to dissolve, then add 1.5g sodium lignosulfonate, and magnetically stir to dissolve evenly. Heat in a water bath until the solution temperature reaches 80°C; then add 25mL of 0.2M Bi(III) dropwise to control the formation of drops but not lines. After the solution was reacted in a constant temperature water bath for 1 hour, it was filtered and washed while it was hot, baked in a constant temperature oven at 60°C for 24 hours, and then calcined in a muffle furnace at 500°C for 3 hours. The XRD pattern of the sample is as follows figure 1 a. Scanning electron microscope picture as figure 2 .

Embodiment 2

[0025] Take 14g NaOH in a beaker, add 175mL deionized water and stir to dissolve, then add 1.0g sodium lignosulfonate, and magnetically stir to dissolve evenly. Heat in a water bath until the solution temperature reaches 80°C; then add 25mL of 0.2M Bi(III) dropwise to control the formation of drops but not lines. After the solution was reacted in a constant temperature water bath for 1 hour, it was filtered and washed while it was hot, baked in a constant temperature oven at 60°C for 22 hours, and then calcined in a muffle furnace at 500°C for 3 hours. The XRD pattern of the sample is as follows figure 1 b.

Embodiment 3

[0027] Take 14g NaOH in a beaker, add 175mL deionized water and stir to dissolve, then add 0.5g sodium lignosulfonate, and magnetically stir to dissolve evenly. Heat in a water bath until the solution temperature reaches 75°C; then add 25 mL of 0.2M Bi(III) dropwise to control the formation of drops but not lines. After the solution was reacted in a constant temperature water bath for 1 hour, it was filtered and washed while it was hot, baked in a constant temperature oven at 50°C for 20 hours, and calcined in a muffle furnace at 400°C for 3 hours. The XRD pattern of the sample is as follows figure 1 c.

[0028] figure 1 Among them, a is the XRD spectrum of the sample in Example 1, b in the figure is the XRD spectrum of the sample in Example 2, and c in the figure is the XRD spectrum of the sample in Example 3. figure 1 Among them, the sharper the peak shape, the better the crystallinity. Curve c has the best crystallinity, which shows that the lower the concentration of s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com