A method for preparing boron nitride nanofibers by arc discharge

An arc discharge, nanofiber technology, applied in chemical instruments and methods, nanotechnology for materials and surface science, nitrogen compounds, etc., can solve the problem of low yield of boron nitride nanofibers, expensive electrode manufacturing, and difficult to remove metal impurities And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A method for preparing boron nitride nanofibers by arc discharge, comprising the following steps:

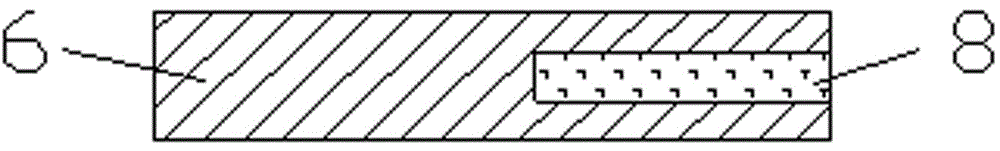

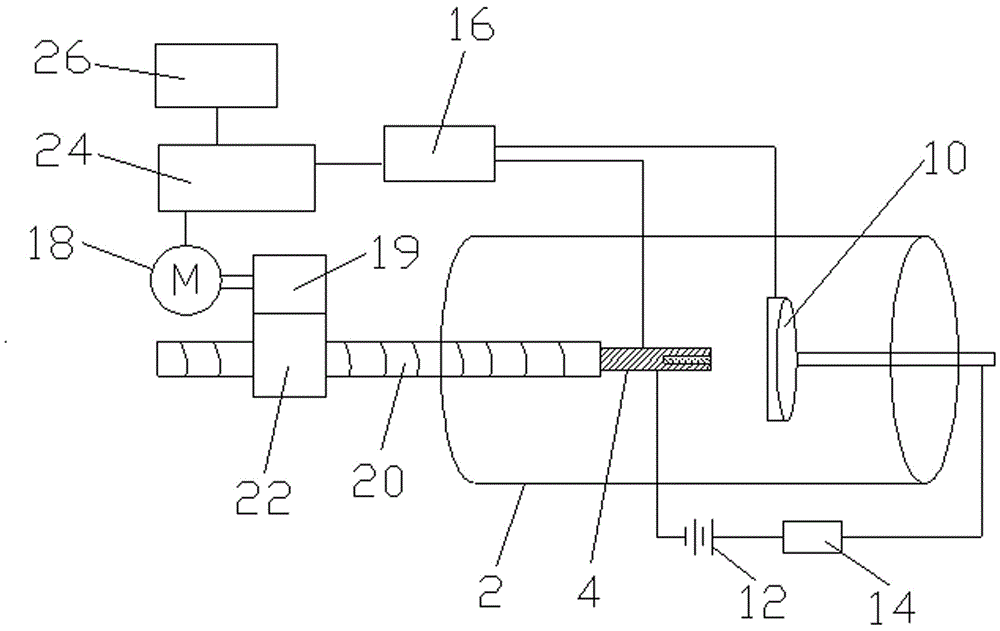

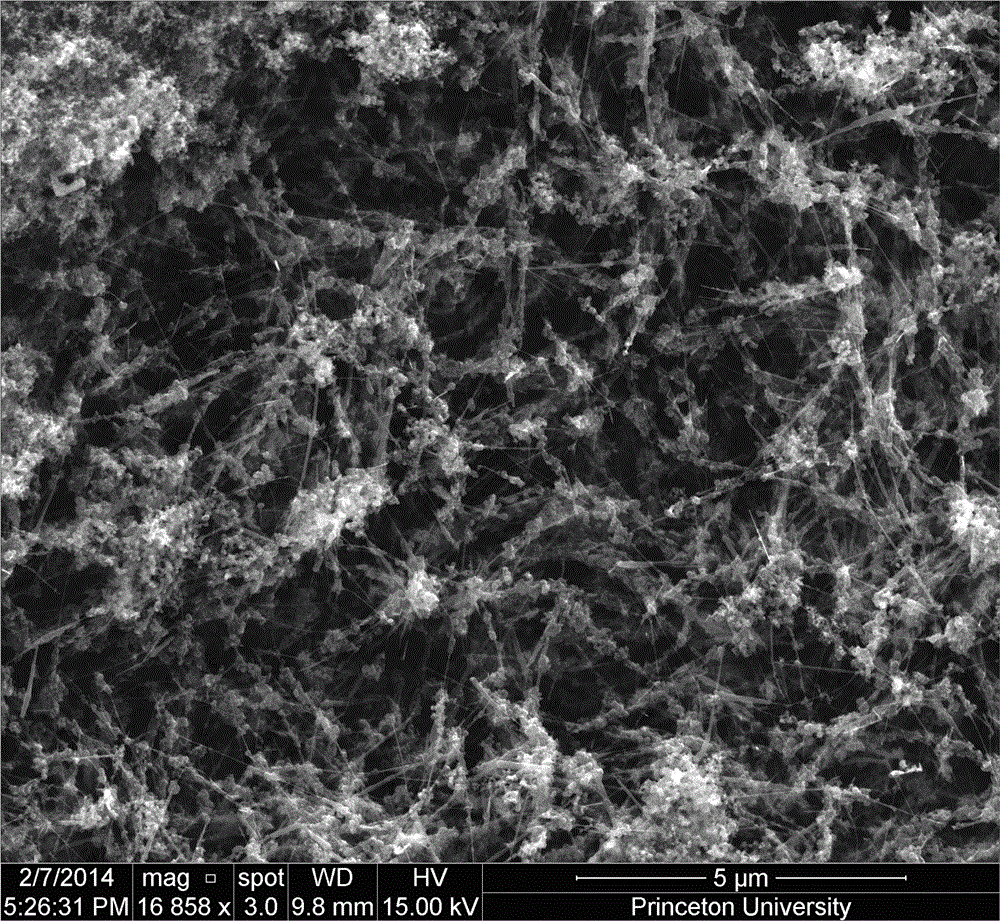

[0031] (1) An arc discharge chamber 2 is provided, and a mixed electrode made of graphite and boron nitride crystal is used as an anode 4. The specific preparation method of the anode 4 is to process a cylindrical graphite rod 6 and a cylindrical hexagonal boron nitride crystal with a small lathe Rod 8, the length of the cylindrical graphite rod 6 after processing is 40mm, and the diameter is 6mm, and the length of the cylindrical hexagonal boron nitride crystal rod 8 is 20mm, and the diameter is 1.5mm, then use lathe on the graphite rod 6 along the A groove with a diameter of 1.5mm and a depth of 20mm is drilled in the axial direction, and finally the boron nitride crystal rod 8 is embedded in the groove of the graphite rod 6, and one end of the boron nitride crystal rod 8 is flush with the notch of the groove. The central axis of the boron nitride crystal rod 8 is on th...

Embodiment 2

[0037] A method for preparing boron nitride nanofibers by arc discharge, comprising the following steps:

[0038](1) An arc discharge chamber 2 is provided, and a mixed electrode made of graphite and boron nitride crystal is used as an anode 4. The specific preparation method of the anode 4 is to process a cylindrical graphite rod 6 and a cylindrical hexagonal boron nitride crystal with a small lathe Rod 8, the length of the cylindrical graphite rod 6 after processing is 60mm, and the diameter is 6mm, and the length of the cylindrical hexagonal boron nitride crystal rod 8 is 20mm, and the diameter is 3mm, and then use a small lathe on the graphite rod 6 along the axis Drill out a groove with a diameter of 3 mm and a depth of 20 mm, and finally embed the boron nitride crystal rod 8 in the groove of the graphite rod 6, one end of the boron nitride crystal rod 8 is flush with the notch of the groove, and then nitrided The central axis of the boron crystal rod 8 is on the same str...

Embodiment 3

[0044] A method for preparing boron nitride nanofibers by arc discharge, comprising the following steps:

[0045] (1) An arc discharge chamber 2 is provided, and a mixed electrode made of graphite and boron nitride crystal is used as an anode 4. The specific preparation method of the anode 4 is to process a cylindrical graphite rod 6 and a cylindrical hexagonal boron nitride crystal with a small lathe Rod 8, the length of the cylindrical graphite rod 6 after processing is 80mm, and diameter is 6mm, and the length of cylindrical hexagonal boron nitride crystal rod 8 is 20mm, and diameter is 4mm, and then use lathe on graphite rod 6 along the axis Drill out a groove with a diameter of 4mm and a depth of 20mm, and finally insert the boron nitride crystal rod 8 into the groove of the graphite rod 6, one end of the boron nitride crystal rod 8 is flush with the notch of the groove, and the nitriding The central axis of the boron crystal rod 8 is on the same straight line as the cent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com