Reinforced type scrambling motorcycle rear fork

A motorcycle and rear flat fork technology, applied in the field of reinforced off-road motorcycle rear flat fork, can solve the problems of welding stress concentration, poor use state, influence, etc., and achieve the effect of improving stability and strengthening structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

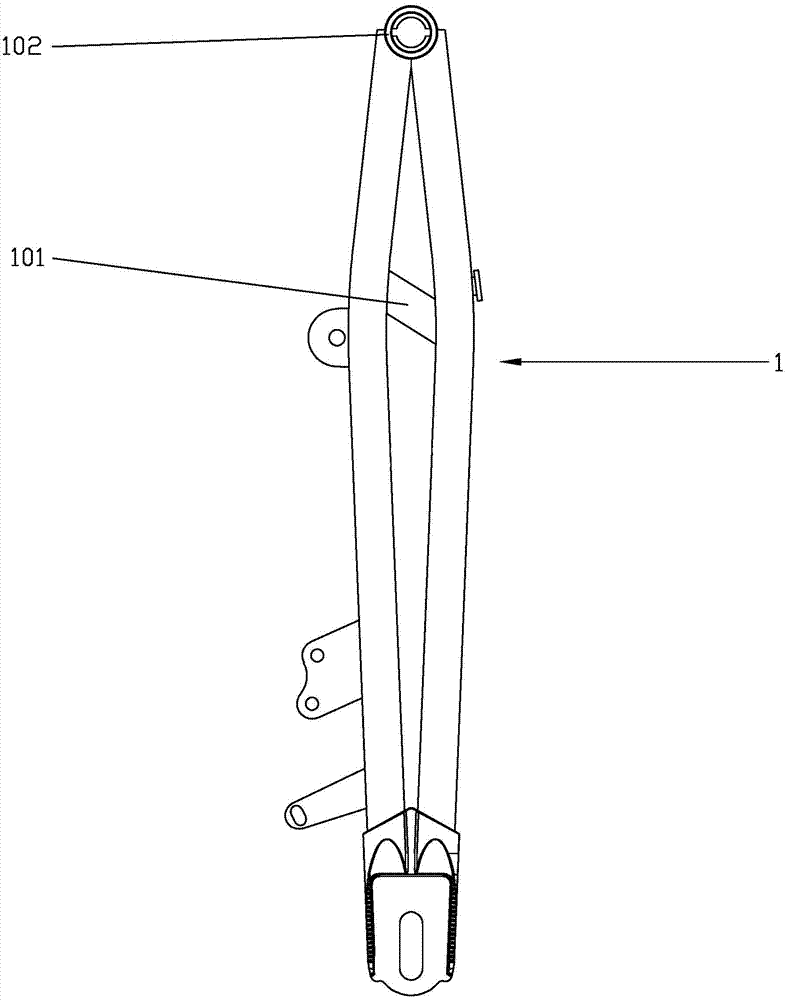

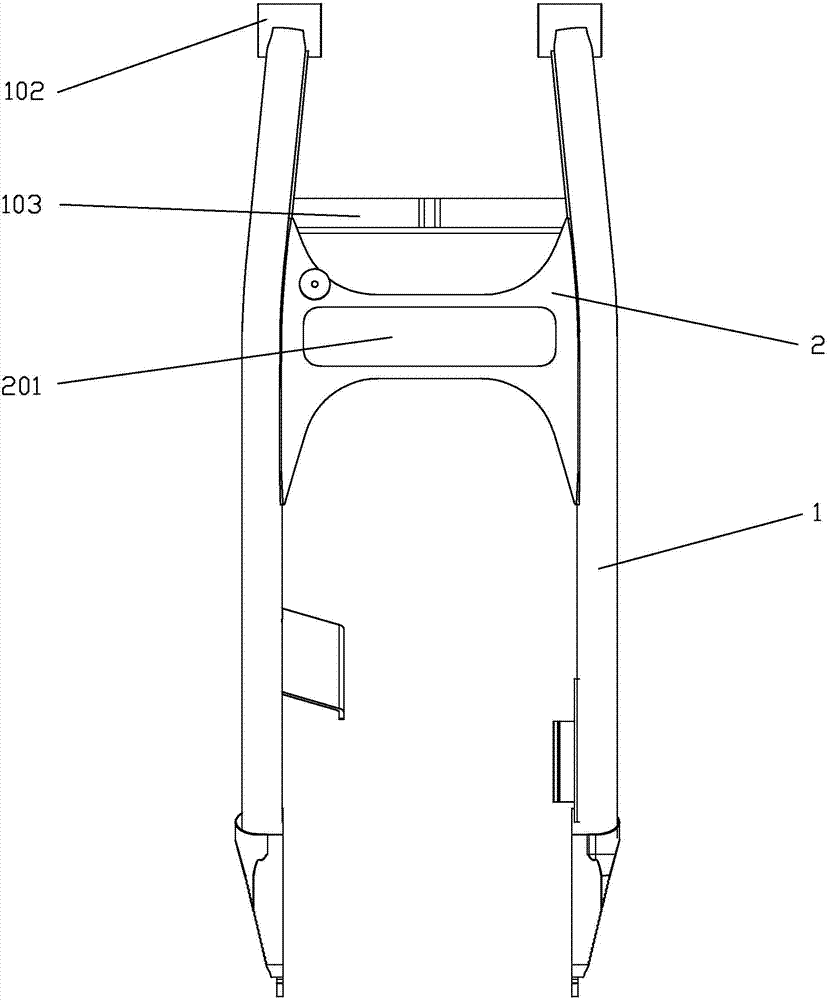

[0015] refer to Figure 1~Figure 2 , a reinforced off-road motorcycle rear flat fork, including two symmetrically arranged flat fork main pipes 1 and a connecting plate 2 connecting the two flat fork main pipes 1, the flat fork main pipe 1 is welded by two seamless pipes The two seamless pipes are bent and welded to form a quadrilateral, and the inner sides of the two flat fork main pipes 1 are also welded with matching reinforcing plates 3 . With the above-mentioned structure, two seamless tubes are combined to form a quadrilateral and then welded into the flat fork main tube 1 of the rear flat fork, which greatly improves the stability of the rear flat fork structure, better decomposes the force received in all directions, and is suitable for off-road motorcycles The use environment; the reinforcement plate 3 welded on the inside of the two flat fork main tubes 1 further strengthens the structural strength of the rear flat fork, ensuring that the flat fork main tube 1 will n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com