Composite tissue engineering skin containing live cells and preparation method for composite tissue engineering skin

A composite tissue, engineering skin technology, applied in medical science, prosthesis, etc., can solve the problems of harsh growth and storage conditions of epidermal living cells, poor ability to isolate external bacteria, easy to cause infection, etc., to improve the isolation of external bacterial infection. Ability, shorten healing time, overcome the effect of being susceptible to external bacterial infection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] On the other hand, an embodiment of the present invention provides a method for preparing composite tissue-engineered skin containing living cells, including:

[0036]After culturing the cell-collagen gel solution on a polymeric material film, a composite tissue-engineered skin containing living cells is obtained. The composite tissue-engineered skin includes a dermis layer and a degradable polymeric material protective layer, and the dermis layer contains human-derived synthetic materials. Fibroblasts or mesenchymal stem cells that can differentiate into fibroblasts.

[0037] Wherein, the polymer material film can be obtained through commercial channels, and can also be obtained by the following preparation method:

[0038] The polymer material solution or melt is jet-spun under the action of a strong electric field to obtain a superfine fiber membrane.

[0039] The obtained microfiber membrane has the characteristics of small pore size, no pollution, good biocompatib...

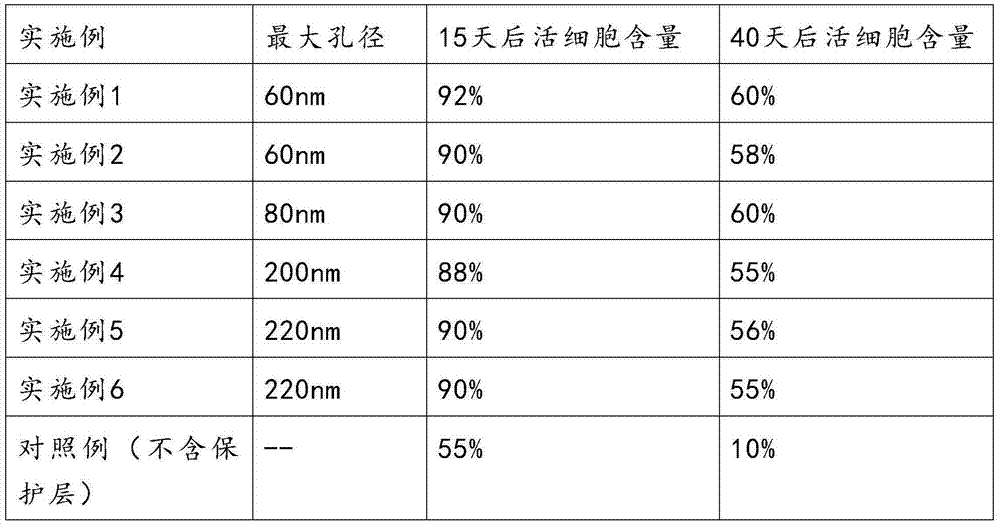

Embodiment 1

[0056] 1. Preparation of polylactic-co-glycolic acid (PLGA) film protective layer.

[0057] Specifically include:

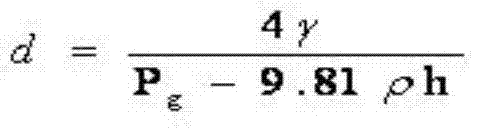

[0058] Preparation of high-voltage electrospun non-woven fabric membrane: Jet-spin the polylactic acid-glycolic acid copolymer solution or melt under the action of a strong electric field to obtain an ultrafine fiber PLGA membrane with a pore size less than or equal to 220nm;

[0059] Collagen gel preparation: Dissolve type I collagen in sterile 0.1% acetic acid and stir until dissolved at a low temperature of 6°C;

[0060] Membrane spreading: Submerge the prepared PLGA membrane into the prepared collagen gel, quickly take it out and lay it on the pitot in the skin slice generator, and solidify at 37°C.

[0061] 2. Prepare the cell-collagen gel solution.

[0062] Add 10% newborn bovine serum and 10% 10 times DMEM culture solution to the prepared collagen gel, adjust the pH to 7.0, and mix well-growing skin fibroblasts with neutral collagen gel to obtain fibrobl...

Embodiment 2

[0068] 1. Preparation of polylactic-co-glycolic acid (PLGA) film protective layer.

[0069] Specifically include:

[0070] Preparation of high-voltage electrospun non-woven fabric membrane: Jet-spin the polylactic acid-glycolic acid copolymer solution or melt under the action of a strong electric field to obtain an ultrafine fiber PLGA membrane with a pore size less than or equal to 220nm;

[0071] Collagen gel preparation: Dissolve type I collagen in sterile 0.05% acetic acid and stir until dissolved at a low temperature of 4°C;

[0072] Membrane spreading: Submerge the prepared PLGA membrane into the prepared collagen gel, quickly take it out and lay it in the pitot of the skin slice generator, and solidify at 32°C.

[0073] 2. Prepare the cell-collagen gel solution.

[0074] Add 4% newborn bovine serum and 5% 8 times DMEM culture solution to the prepared collagen gel, adjust the pH to 6.0, and mix well-growing skin fibroblasts with neutral collagen gel to obtain fibroblas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com