Preparation method and application of removing agent for heavy metal cadmium in mussels

A technology of heavy metal and remover, applied in the application, food preparation, food science and other directions, to achieve the effect of simple process, enhanced immunity, and simple process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

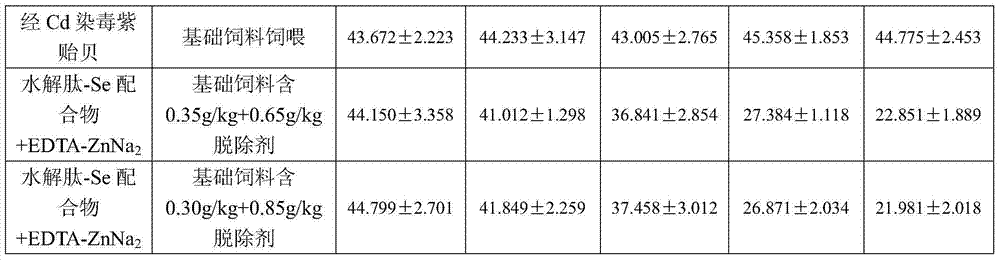

Examples

Embodiment 1

[0022] A kind of preparation method of heavy metal cadmium removing agent in mussel, concrete steps are as follows:

[0023] 1. Take hairtail processing by-products, add phosphate buffer solution with a pH value of 7.0 and a concentration of 0.18mol / L. The amount of phosphate buffer solution added is 5 times the volume of hairtail processing by-products, and the tissues are crushed and ultrasonically treated at 37KHz for 4 minutes. Finally, add 8g / L of compound hydrolase, which is composed of flavor protease and papain in a mass ratio of 2:1, the hydrolysis temperature is controlled at 50°C, and the degree of protein hydrolysis is 28%;

[0024] 2. Raise the temperature to 90°C and keep it for 2.5 minutes, then quickly cool it in an ice bath, centrifuge at 4000r / min, and centrifuge for 15 minutes to obtain the supernatant, which is the hairtail processing by-product protein hydrolyzate;

[0025] 3. Add sodium selenite to hairtail processing by-product protein hydrolyzate (the a...

Embodiment 2

[0032] A kind of preparation method of heavy metal cadmium removing agent in mussel, concrete steps are as follows:

[0033] 1. Take hairtail processing by-products, add phosphate buffer solution with a pH value of 6.8 and a concentration of 0.05mol / L, the amount of phosphate buffer added is 6 times the volume of hairtail processing by-products, break the tissue, and 30KHz ultrasonic treatment for 5 minutes Finally, add 10g / L of compound hydrolase, which is composed of flavor protease and papain in a mass ratio of 1:1, the hydrolysis temperature is controlled at 40°C, and the degree of protein hydrolysis is 24%;

[0034] 2. Raise the temperature to 85°C, keep it for 3 minutes, cool it in an ice bath, centrifuge at 4500r / min, and centrifuge for 10 minutes to obtain the supernatant, which is the protein hydrolyzate by-product of hairtail processing;

[0035] 3. Add sodium selenite to hairtail processing by-product protein hydrolyzate (the addition amount is controlled so that th...

Embodiment 3

[0042] A kind of preparation method of heavy metal cadmium removing agent in mussel, concrete steps are as follows:

[0043]1. Take hairtail processing by-products, add phosphate buffer solution with a pH value of 7.4 and a concentration of 0.20 mol / L, the amount of phosphate buffer added is 3 times the volume of hairtail processing by-products, crush the tissue, and ultrasonically treat at 45KHz for 2 minutes Finally, 6g / L of compound hydrolase was added. The compound hydrolase was mixed with flavor protease and papain at a mass ratio of 3:1. The hydrolysis temperature was controlled at 60°C, and the degree of protein hydrolysis was 32%;

[0044] 2. Raise the temperature to 95°C, keep it for 2 minutes, then quickly cool it in an ice bath, centrifuge at 3000r / min, and centrifuge for 20 minutes to obtain the supernatant, which is the hairtail processing by-product protein hydrolyzate;

[0045] 3. Add sodium selenite to hairtail processing by-product protein hydrolyzate (the add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com