Method for constructing artificial rock large structure

A construction method and large-scale structure technology, which can be applied to infrastructure engineering, artificial islands, underwater structures, etc., can solve problems such as easy separation of handrails, easy corrosion of steel bars, and low structural strength, so as to improve structural stability and maintain durability performance, improving structural strength and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0026] Below with reference to accompanying drawing, describe in detail the embodiment of the artificial rock construction method of large-scale structure of the present invention.

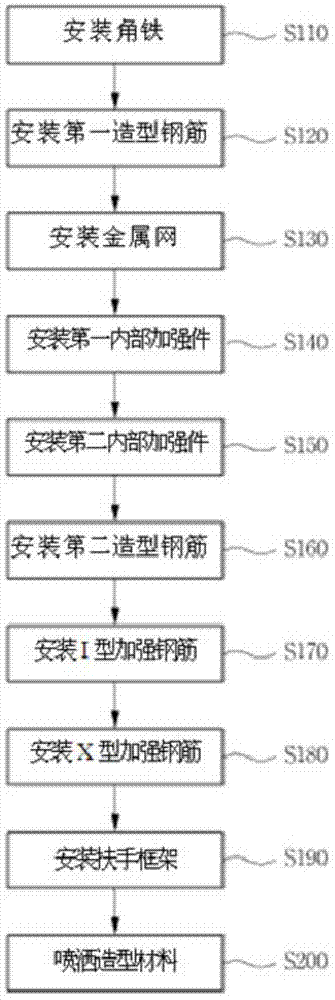

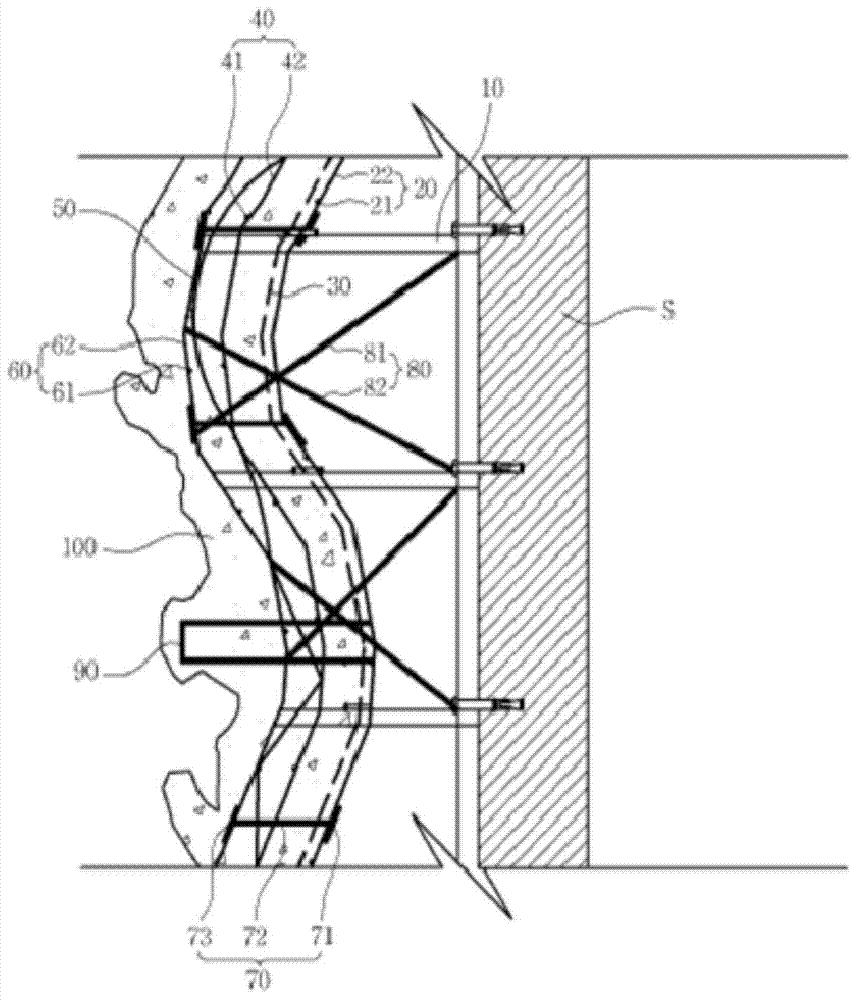

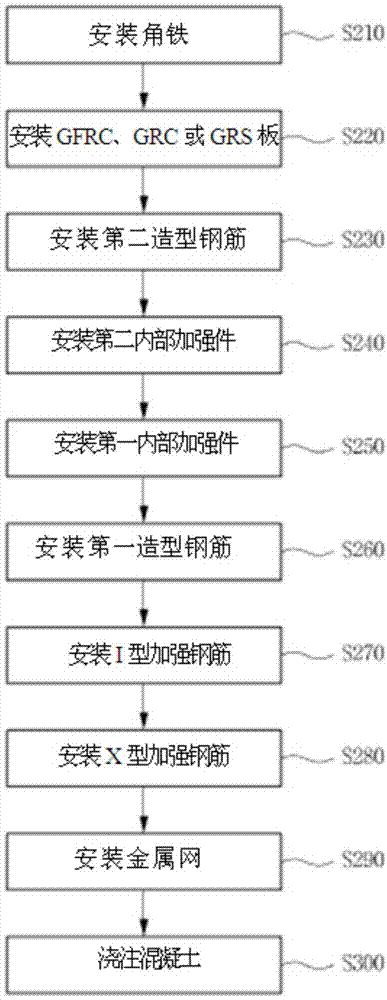

[0027] figure 1 It is a block diagram showing a method of artificial rock construction by means of spraying of modeling materials in the artificial rock construction method of large-scale structure of the present invention, figure 2 is displayed according to figure 1 A diagram of the situation of the artificial rock constructed by the method shown.

[0028] figure 1 The artificial rock construction method of the large-scale structure of the present invention shown is roughly completed through the process of 10 steps.

[0029] The first step S110 is the process of installing multiple angle irons 10 on the structure S. One side end of the angle iron 10 is firmly fixed to the structure S by means of coupling such as nuts or anchor bolts.

[0030]A plurality of angle irons 10 are installed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com