A kind of negative electrode material of lithium ion battery and its preparation method and application

A lithium-ion battery and negative electrode material technology, which is applied in the direction of battery electrodes, circuits, electrical components, etc., to achieve the effect of improving rate performance, large capacity, and increasing capacity and charge-discharge rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Example 1 Lithium-ion battery negative electrode material

[0019] (1) Preparation method

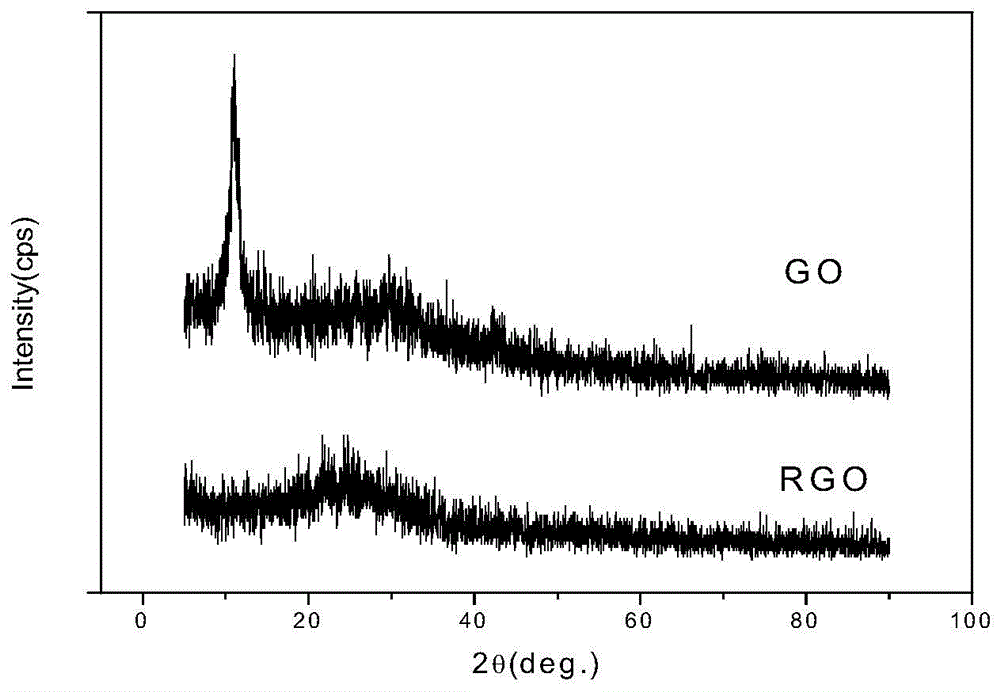

[0020] Dissolve 65-70mL of concentrated H 2 S0 4 Place in an ice-water bath, add 1.9-2.2g of graphite and 1.5-1.7g of NaNO under stirring at 100-240r / min 3 , after stirring evenly, add 8 ~ 10g KMnO 4 , reacted for 15 to 30 minutes, and added H after the reaction 2 o 2 Until the solution turns bright yellow, centrifuge and wash to obtain graphene oxide (GO).

[0021] 3.15g TiOSO 4 2H 2 O was dissolved in 40ml deionized water to obtain TiOSO 4 solution, take 30ml TiOSO 4 After the solution was mixed with 0.02050g of GO, it was added to 70ml of ethylene glycol, ultrasonically treated for 20min, then added to 90ml of aqueous solution containing 2.02g of LiOH and 0.6g of urea, added 0.6g of glucose, and stirred for 3min to obtain a mixed solution. Put the mixed solution into the reaction kettle, react at 180°C for 24h, filter, take the precipitate, wash, dry at 80°C for 24h,...

Embodiment 2

[0025] Example 2 Lithium-ion battery negative electrode material

[0026] (1) Preparation method

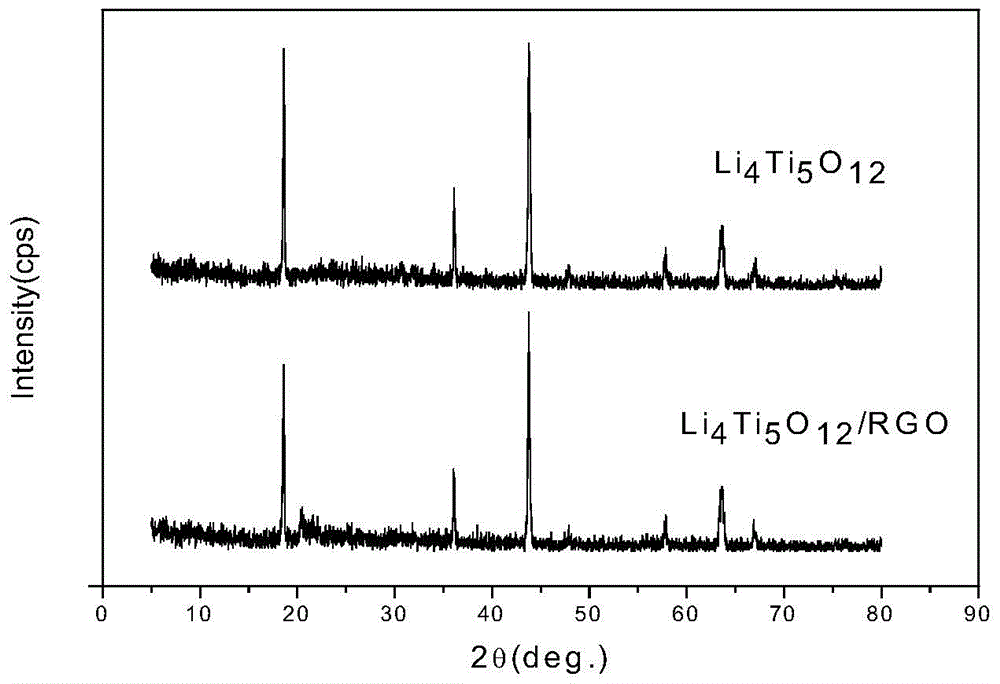

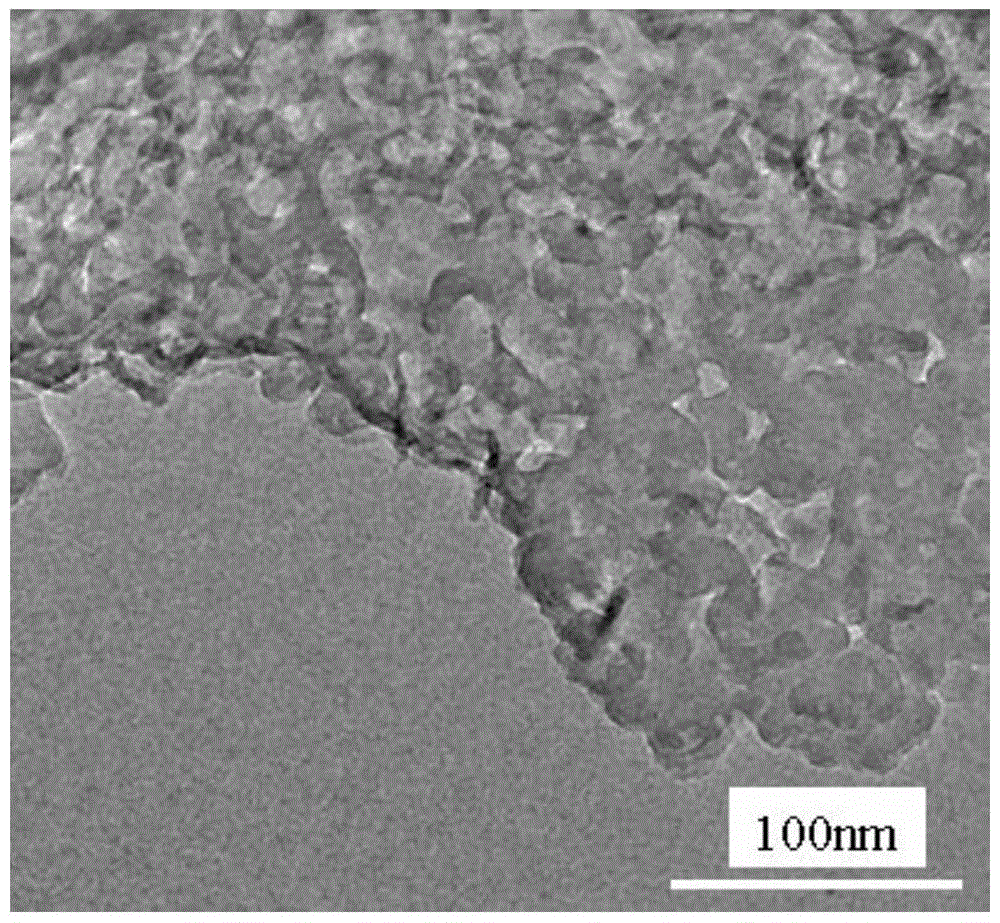

[0027] 3.15g TiOSO 4 2H 2 O was dissolved in 40ml deionized water to obtain TiOSO 4 solution, take 30ml TiOSO 4 After the solution was mixed with 0.02055g of GO, it was added to 70ml of ethylene glycol, ultrasonically treated for 20min, then added to 90ml of aqueous solution containing 2.02g of LiOH and 0.6g of urea, added 0.6g of glucose, and stirred for 3min to obtain a mixed solution. Put the mixed solution into the reaction kettle, react at 180°C for 24h, filter, take the precipitate, wash, dry at 80°C for 24h, and calcine it under N 2 Under the atmosphere, calcining at 500° C. for 2 hours, then heating up to 700° C. and calcining for 10 hours, to obtain the lithium ion battery negative electrode material. The negative electrode material of lithium ion battery is a composite of lithium titanate and reduced graphene oxide.

[0028] The obtained composite of lithium titanat...

Embodiment 3

[0029] Example 3 Lithium ion battery negative electrode material

[0030] (1) Preparation method

[0031] 3.15g TiOSO 4 2H 2 O was dissolved in 40ml deionized water to obtain TiOSO 4 solution, take 30ml TiOSO 4 After the solution was mixed with 0.02060g of GO, it was added to 70ml of ethylene glycol, ultrasonically treated for 20min, then added to 90ml of aqueous solution containing 2.02g of LiOH and 0.6g of urea, added 0.6g of glucose, and stirred for 3min to obtain a mixed solution. Put the mixed solution into the reaction kettle, react at 180°C for 24h, filter, take the precipitate, wash, dry at 80°C for 24h, and calcine it under N 2 Under the atmosphere, calcining at 500° C. for 2 hours, then heating up to 700° C. and calcining for 10 hours, to obtain the lithium ion battery negative electrode material. The negative electrode material of lithium ion battery is a composite of lithium titanate and reduced graphene oxide.

[0032] The obtained composite of lithium titan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com