Cyclodextrin modified nano-silver hydrogel, and preparation method and application thereof

A technology of nano-silver sol and cyclodextrin, which is applied in the field of nano-materials, can solve the problems of low uniformity and preparation difficulties of nano-silver sol or gel, and improve the ability of adsorption and measurement, strengthen the uniformity of dispersion, and facilitate operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The preparation method of the nano-silver hydrogel modified by reduction in situ of the dextrin comprises the following steps:

[0028] (1) Uniformly mix cyclodextrin and silver salt aqueous solution to obtain a mixture, wherein each gram of cyclodextrin corresponds to 0.2 mmol to 5 mmol of silver salt, and the concentration of silver salt is between 0.1 mmol per liter and 2.5 mmol per liter ; adjust the pH value of the mixture between 11 and 13, maintain the temperature between 50°C and 90°C, and react for 0.5 hours to 2 hours to obtain cyclodextrin-modified nano-silver sol. Preferably, the particle size of the nano-silver particles in the cyclodextrin-modified nano-silver sol is between 20nm and 50nm.

[0029] (2) The cyclodextrin-modified nano-silver sol obtained in step (1) is added with a gelling factor, and the cyclodextrin-modified nano-silver gel is obtained by freezing and gelling.

[0030] Preferably, the gelling factor is polyvinyl alcohol, and the added mas...

Embodiment 1

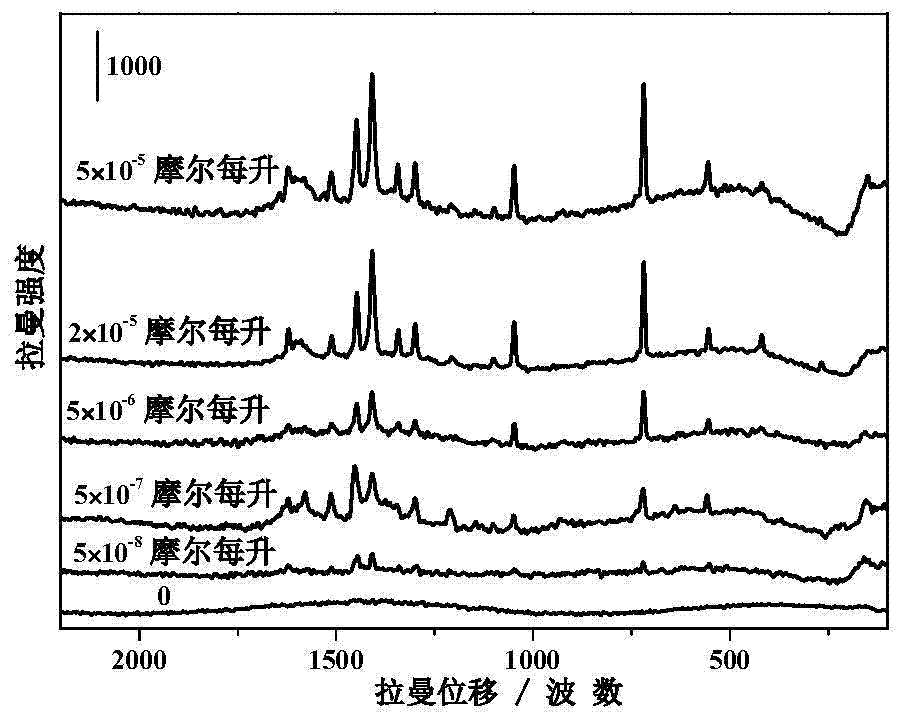

[0035] A nano-silver hydrogel modified by in-situ reduction of cyclodextrin, containing 0.1% by mass percentage of nano-silver particles modified by in-situ reduction of cyclodextrin, and the particle size of the cyclodextrin-modified nano-silver particles is 20 -30nm, uniformly dispersed in the hydrogel, the cyclodextrin is evenly distributed on the surface of the nano-silver particles, the mass ratio of the cyclodextrin to the nano-silver particles is 50:1, and the hydrogel modified by the cyclodextrin The tensile strength of the glue is between 3.5-4.0 MPa, and the relative standard deviation of the measured molecular surface scanning Raman signal is 8.3%. The hydrogel is preferably polyvinyl alcohol hydrogel, wherein the mass percentage of polyvinyl alcohol is 5%. The cyclodextrin is α-cyclodextrin.

[0036] The preparation method of the nano-silver hydrogel modified by reduction in situ of the dextrin comprises the following steps:

[0037] (1) Take 2 ml of 0.01 mol per l...

Embodiment 2

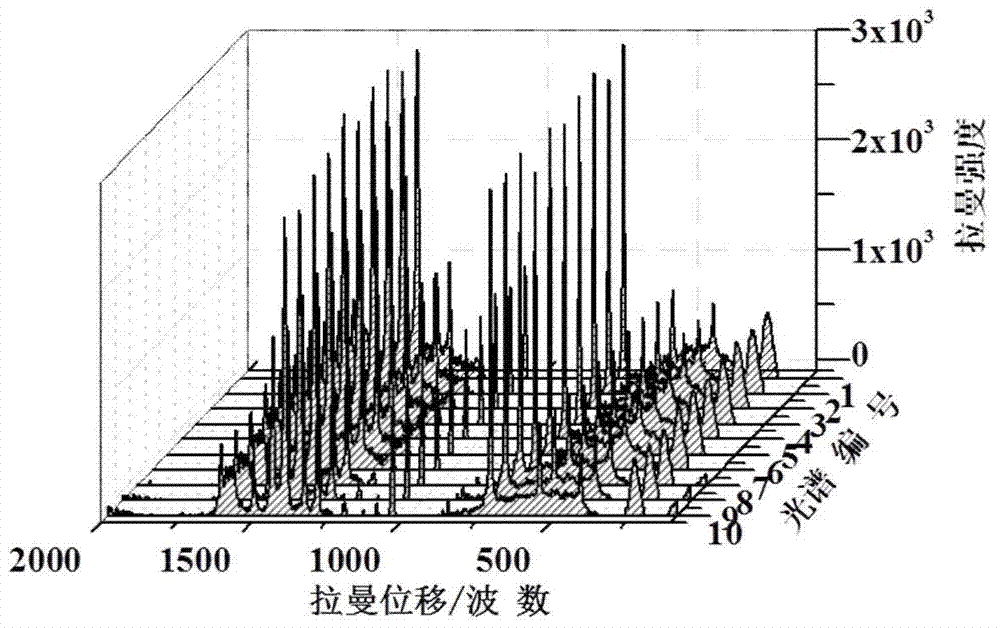

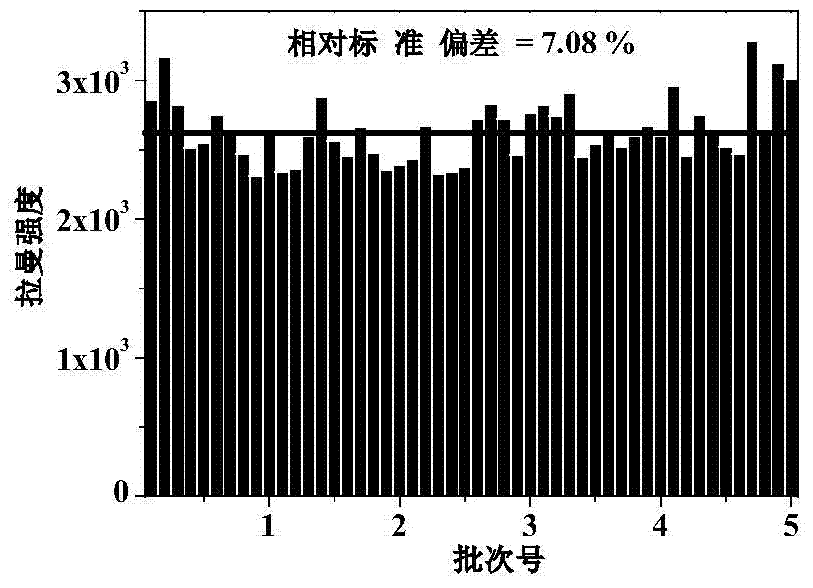

[0042] A nano-silver hydrogel modified by in-situ reduction of cyclodextrin, containing 0.2% by mass percentage of nano-silver particles modified by in-situ reduction of cyclodextrin, the particle size of the cyclodextrin-modified nano-silver particles is 30 -40nm, uniformly dispersed in the hydrogel, the cyclodextrin is evenly distributed on the surface of the nano-silver particles, the mass ratio of the cyclodextrin to the nano-silver particles is 10:1, and the hydrogel modified by the cyclodextrin The tensile strength of the glue is between 4.0-5.0 MPa, and the relative standard deviation of the measured molecular surface scanning Raman signal is 7.08%. The hydrogel is preferably polyvinyl alcohol hydrogel, wherein the mass percentage of polyvinyl alcohol is 10%. The cyclodextrin is β-cyclodextrin.

[0043] The preparation method of the nano-silver hydrogel modified by reduction in situ of the dextrin comprises the following steps:

[0044] (1) Take 2 milliliters of 0.01 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com