In-Situ Micro/Nano Indentation/Scratch Test Method

A scratch test, micro-nano technology, applied in the direction of testing the hardness of materials, measuring devices, instruments, etc., can solve the problems of scratch force fluctuations, unable to quantitatively detect the normal force and tangential force of the scratch process, and achieve a compact structure , broad development prospects and application value, and the effect of ensuring assembly accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

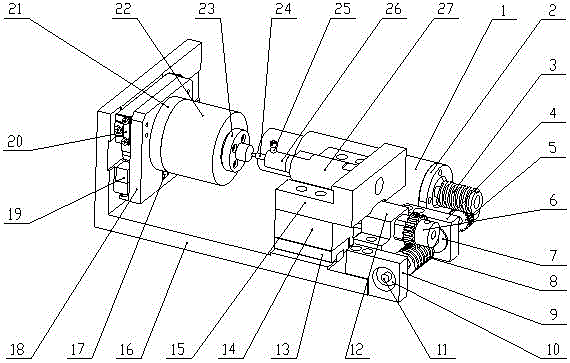

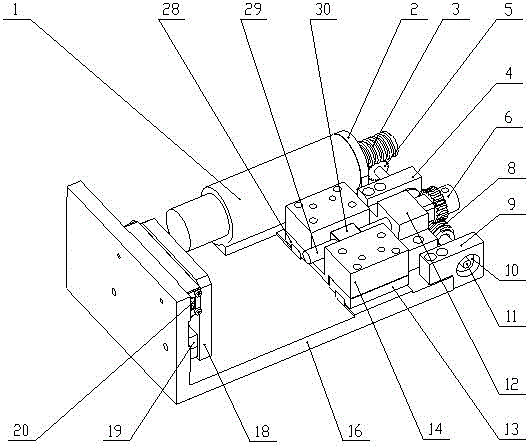

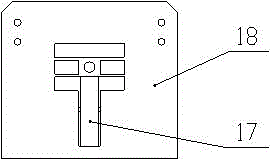

[0033] The detailed content of the present invention and its specific implementation will be further described below in conjunction with the accompanying drawings.

[0034] see Figure 1 to Figure 4 As shown, the in-situ micro-nano indentation / scratch test platform of the present invention includes an X-axis precision scratch unit, a Y-axis large-stroke stick-slip drive scratch assembly, a Z-axis macro adjustment mechanism, a precision press-in drive unit and The displacement signal detection unit, the load signal detection unit, etc., wherein the X-axis precision scratch unit and the Y-axis large-stroke stick-slip driver scratch assembly are assembled at the tail of the base 16, and the Z-axis macro adjustment mechanism is assembled at the middle of the base 16. The motor drive unit is assembled on the base head. The precision press-in drive unit and the displacement signal detection unit 27 are installed on the Z-axis macro adjustment mechanism, and the precision three-axis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com