An Ultrasonic On-Line Measuring Device for Abrasion Amount

A measuring device and technology of wear amount, which are applied in ultrasonic online measurement of wear amount in wear test and friction field, can solve the problems of in-situ, fast, online measurement, inconvenient online measurement of wear amount, etc., and achieve wide practicability and structure. Simple, easy to capture and analyze effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

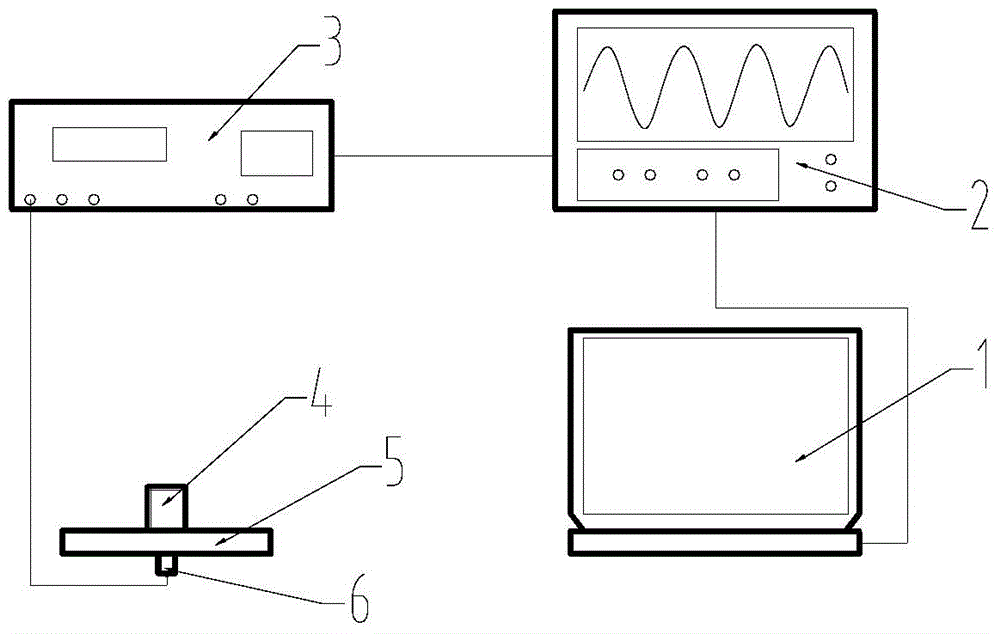

[0013] The ultrasonic on-line measurement device for wear amount of the present invention is mainly composed of a friction pair upper test piece 4 , a friction pair lower test piece 5 , an ultrasonic probe 6 , a pulse transmitter receiver 3 , a digital oscilloscope 2 , and a computer 1 . The ultrasonic probe 6 is an ultrasonic longitudinal wave probe, or a vertically incident ultrasonic transverse wave probe. The upper test piece 4 of the friction pair is located on the lower test piece 5 of the friction pair that can be reciprocated, and the upper test piece 4 of the friction pair is fixed; the ultrasonic probe 6 is located at the bottom of the lower test piece 5 of the friction pair to obtain The amount of change in ultrasonic propagation time caused by the thickness change of the test piece 5 under the friction pair is reversely calculated for the wear a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com