Light emitting diode bulb with central axis bidirectional convection heat dissipation structure

A technology of light emitting diodes and heat dissipation structures, which is applied to semiconductor devices, lamp shades, light sources, etc. of light emitting elements, can solve the problems of user burns, difficult manufacturing, and high production costs, and achieves extended service life, low lamp housing structure, and avoidance of burns. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to facilitate the examiner to further understand and understand the purpose, structure and effect of the present invention, the following examples are given in conjunction with the drawings, and the details are as follows:

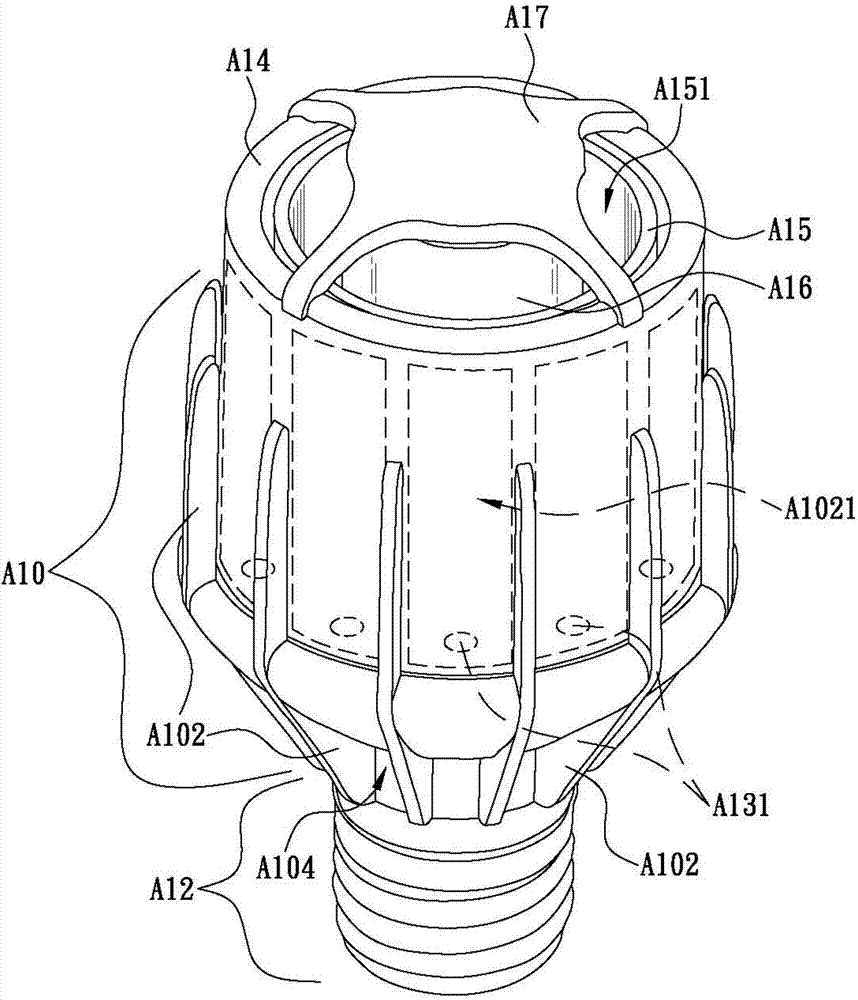

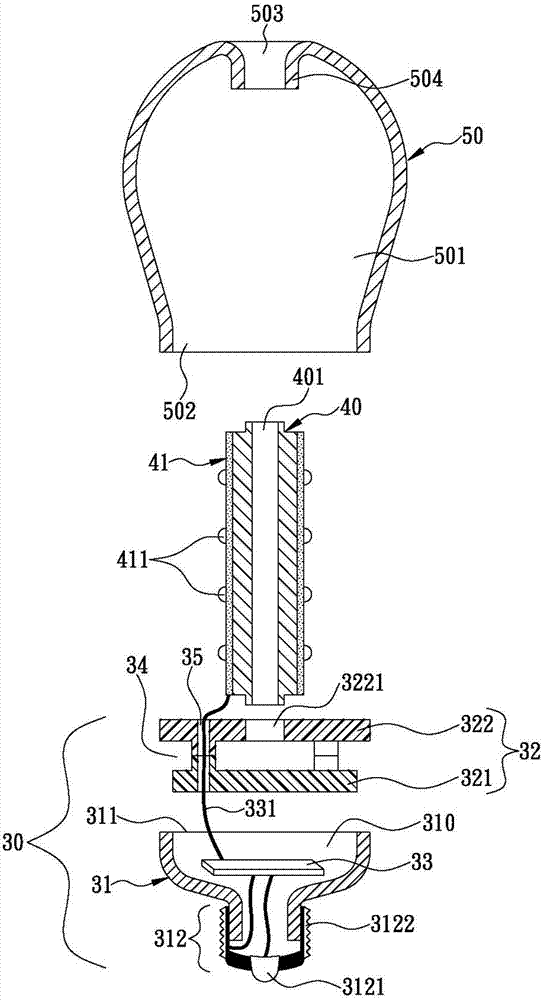

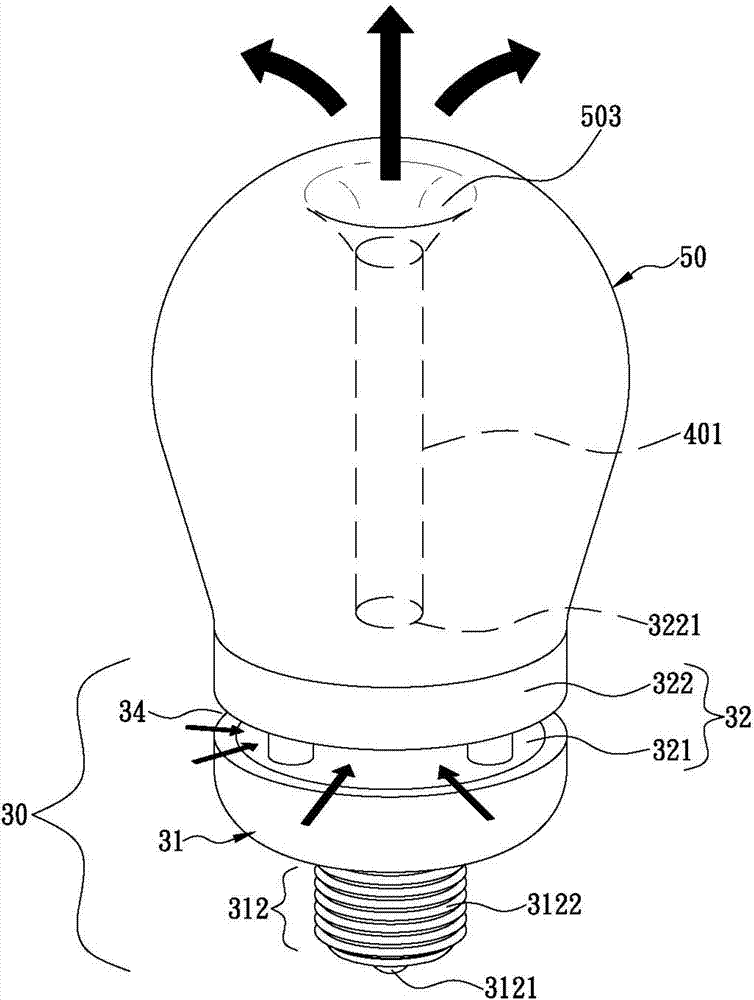

[0043] like figure 2 and image 3 As shown, the inventor's light-emitting diode bulb with a central axis bidirectional convection heat dissipation structure has a minimal structure. The inventor divides the entire light-emitting diode bulb into two parts to make an upper lamp housing and a lower lamp housing, and then the The upper lamp housing and the lower lamp housing are combined to make the structure of the bulb extremely simplified, thereby effectively reducing the production difficulty and production cost, and the related heat dissipation elements can be completely covered in the bulb, so as to effectively prevent users from touching these components. Accidents of burns due to heat dissipation components.

[0044] In the first pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com