Washing machine as well as water level and overweight detection device and method

A detection device and washing machine technology, applied in the field of washing machines, can solve problems such as low production efficiency, difficulty in installation, complex circuit structure, etc., and achieve the effects of saving space, easy installation, and simplified circuit structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

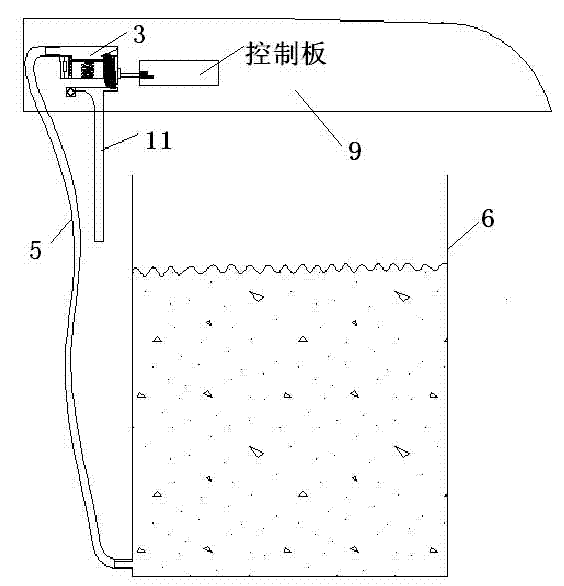

[0026] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

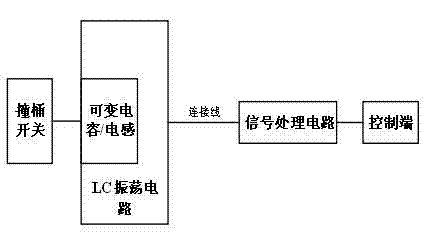

[0027] Such as figure 1 As shown, this embodiment proposes a water level and weight detection device for a washing machine, including an integrated water level sensor and a bucket switch, wherein the water level sensor includes an LC oscillation circuit at least composed of a capacitor and an inductance, and the LC oscillation circuit includes At least one capacitor with variable capacitance value and / or at least one inductor with variable inductance value, the bump switch is connected to the LC oscillating circuit. The LC oscillating circuit is connected to the signal processing circuit on the control board through the connection line, and the signal processing circuit performs signal processing and transmits the processed signal to the control terminal.

[0028] The signal processing circuit includes a signal amplification circuit and a fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com