A method for quickly removing waste and residual iron in a blast furnace during overhaul

A technology for blast furnaces and residual iron, applied to blast furnaces, blast furnace details, blast furnace parts, etc., can solve the problems of cleaning manual operations, time-consuming and labor-intensive cycles, etc., and achieve the effects of improving cleaning speed, convenient operation, and safe construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

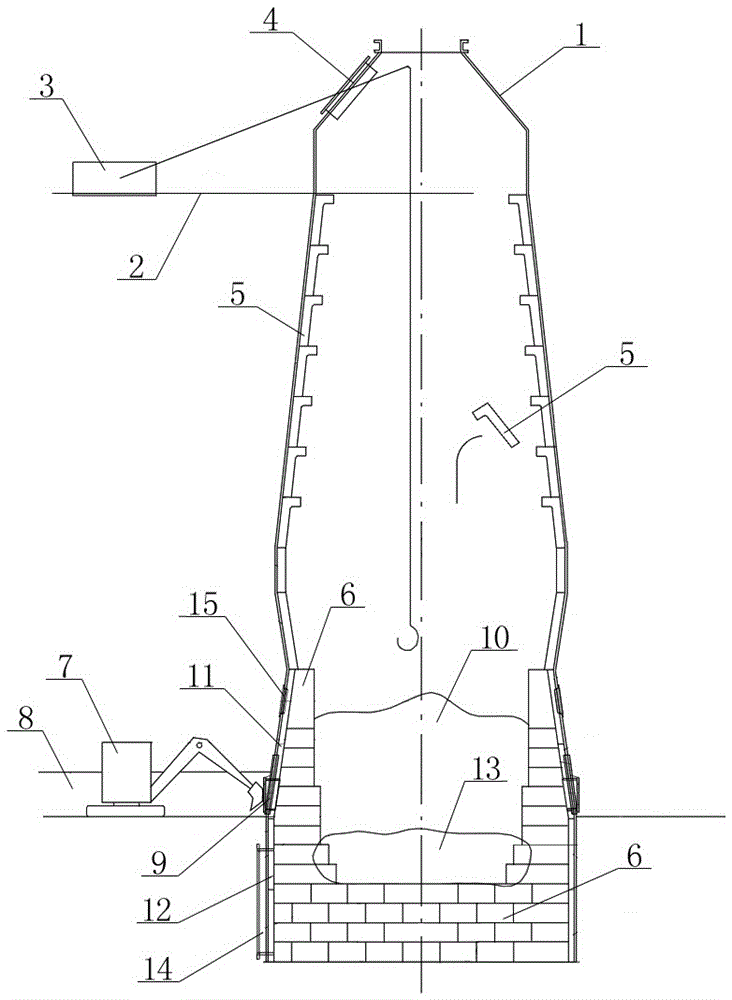

[0018] The used tool of the present invention comprises: one 60-type excavator, two gas welding and cutting torches, some 5-ton chain-reversing, some 30-ton jacks, and three 100-ton jacks. see figure 1 As shown, the rapid removal method of scrap and residual iron in the furnace in the blast furnace overhaul of the present invention comprises the following steps:

[0019] a. After the blast furnace stops ironmaking and the residual iron in the blast furnace is released, first use a water gun to pump water from the manhole 4 on the furnace roof of the blast furnace body 1 to cool down the furnace until the temperature in the furnace drops to a level suitable for construction personnel. When the entering temperature (about 20-30°C) can stop the operation of fetching water and cooling down.

[0020] b. Construction workers remove the large, middle and small sets of all the hot air outlets 15 on the blast furnace body 1 and transport them away from the blast furnace.

[0021] c. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com