A kind of high-viscosity and high-elasticity asphalt based on surface modification of rubber particles, SMA asphalt mixture and preparation method thereof

A rubber particle and surface modification technology, which is applied to building insulation materials, building components, buildings, etc., can solve the problems of limited improvement of viscoelastic properties of asphalt, poor storage stability of rubber particles, and influence of pavement material performance, etc., to achieve water resistance Improved stability and fatigue resistance, improved storage stability, and reduced compaction difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

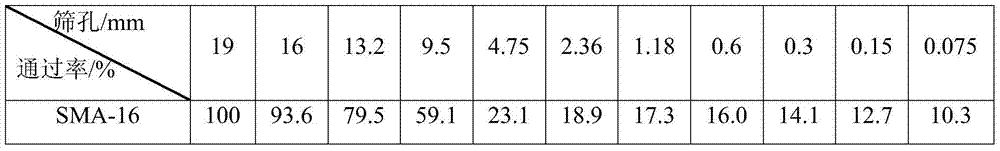

Embodiment 1

[0028] 1) High-viscosity and high-elasticity asphalt

[0029] A high-viscosity and high-elasticity asphalt based on the surface modification of rubber particles, with base asphalt, activated rubber powder, weather-resistant components, tackifying components (C5 petroleum resin), plasticizing components (dioctyl phthalate) , compatibilization component (minus second-line extraction oil) and cross-linking component (dicumyl peroxide) are prepared as raw materials, and the specific preparation steps are as follows:

[0030] a) Preparation of activated rubber powder: Weigh the raw materials according to the mass ratio of rubber powder (80 mesh bias tire vulcanized rubber powder) and surface activation component to 100:5; first, stir the rubber powder in a stirring pot at 40°C for 120s; Then, divide and add surface activation component three times, the amount that adds for the first time and the second time is 40% of total amount (surface activation component total mass), and stirs...

Embodiment 2

[0048] 1) High-viscosity and high-elasticity asphalt

[0049] A kind of high-viscosity and high-elasticity asphalt based on the surface modification of rubber particles, with base asphalt, activated rubber powder, weather-resistant components, tackifying components (adhesive resin), plasticizing components (dibutyl phthalate) , compatibilizing component (furfural extracted oil) and crosslinking component (sulfur) are prepared as raw materials, and the specific preparation steps are as follows:

[0050] a) Preparation of activated rubber powder: Weigh the raw materials according to the mass ratio of rubber powder (40 mesh or 80 mesh bias tire vulcanized rubber powder) to the surface active component as 100:25; first put the rubber powder in a stirring pot at 50°C Stir for 80s; Then, add the surface active component in three stages, the amount added for the first time is 20% of the total amount (the total mass of the surface active component), stir for 5min, and the amount added...

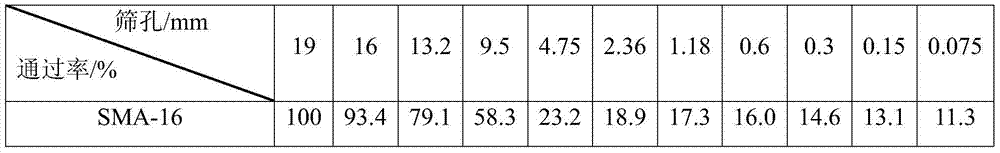

Embodiment 3

[0067] 1) High-viscosity and high-elasticity asphalt

[0068] A high-viscosity and high-elasticity asphalt based on the surface modification of rubber particles, with base asphalt, activated rubber powder, weather-resistant components, tackifying components (rosin resin), plasticizing components (dibutyl phthalate), The compatibilization component (minus third-line extraction oil) and cross-linking component (sulfur) are prepared as raw materials, and the specific preparation steps are as follows:

[0069] a) Preparation of activated rubber powder: Weigh the raw materials according to the mass ratio of rubber powder (80 mesh bias tire vulcanized rubber powder) and surface active component to 100:30; first, stir the rubber powder in a stirring pot at 55°C for 60 seconds; Then, add surface active component in three stages, the amount that adds for the first time is 10% of total amount (surface active component total mass), stirs 5min, the amount that adds for the second time is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap