Non-migration type PVC (polyninyl chloride) environment-friendly plastic material and preparation method thereof

An environmentally friendly plastic, non-migration technology, applied in the field of environmentally friendly plastic materials, can solve the problems of endocrine disruption, easy migration and exudation of plasticizers, affecting the appearance of products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A non-migrating PVC environment-friendly plastic material, the PVC environment-friendly plastic is prepared by mixing and stirring the components of the following formula in parts by weight:

[0048] PVC resin 100;

[0049] light calcium carbonate 40;

[0050] Non-toxic calcium zinc stabilizer 6;

[0051] PE wax 0.4;

[0052] Saturated polyester resin PN-1030 50;

[0053] Epoxidized soybean oil 3.

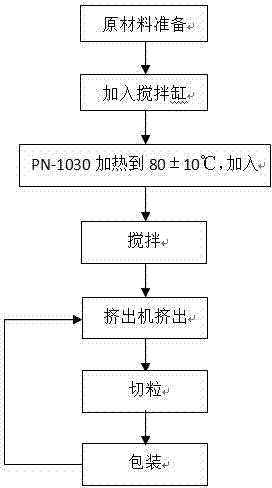

[0054] The preparation method of this PVC environment-friendly plastic comprises the following steps:

[0055] a) By recipe

[0056] Weigh 50kg of PVC resin, 20kg of light calcium carbonate, 3kg of non-toxic calcium zinc stabilizer, 0.2kg of PE wax, and 1.5kg of epoxy soybean oil, and feed them into a 300L stirring tank;

[0057] b) Weigh 25kg of saturated polyester resin PN-1030, heat it to 80°C, add it into the mixing tank in 3 times, the addition ratio is 50%, 30%, 20%, the first time is added and stirred for 5 minutes, the second time Add and stir for 2m...

Embodiment 2

[0064] A non-migrating PVC environment-friendly plastic material, the PVC environment-friendly plastic is prepared by mixing and stirring the components of the following formula in parts by weight:

[0065] PVC resin 100;

[0066] light calcium carbonate 30;

[0067] Non-toxic calcium zinc stabilizer 6;

[0068] PE wax 0.6;

[0069] Saturated polyester resin PN-1030 40;

[0070] Epoxidized soybean oil 3.

[0071] The preparation method of this PVC environment-friendly plastic comprises the following steps:

[0072] a) By recipe

[0073]Weigh 100kg of PVC resin, 30kg of light calcium carbonate, 6kg of non-toxic calcium zinc stabilizer, 0.6kg of PE wax, and 3kg of epoxy soybean oil, and feed them into a 500L mixing tank;

[0074] b) Weigh 40kg of saturated polyester resin PN-1030, heat it to 80°C, add it into the mixing tank twice, the addition ratio is 50% and 50%, and stir for 10 minutes after the first addition;

[0075] c) Mixing and stirring: After all the ...

Embodiment 3

[0080] A non-migrating PVC environment-friendly plastic material, the PVC environment-friendly plastic is prepared by mixing and stirring the components of the following formula in parts by weight:

[0081] PVC resin 100;

[0082] light calcium carbonate 50;

[0083] Non-toxic calcium zinc stabilizer 6;

[0084] PE wax 0.5;

[0085] Saturated polyester resin PN-1030 60;

[0086] Epoxidized soybean oil 4.

[0087] The preparation method of this PVC environment-friendly plastic comprises the following steps:

[0088] a) By recipe

[0089] Weigh 100kg of PVC resin, 50kg of light calcium carbonate, 6kg of non-toxic calcium zinc stabilizer, 0.5kg of PE wax, 4kg of epoxy soybean oil, and feed them into a 500L stirring tank;

[0090] b) Weigh 60kg of saturated polyester resin PN-1030, heat it to 80°C, and add it into the mixing tank in 4 times. The stirring time is 10min, 5min, 3min;

[0091] c) Mixing and stirring: After all the raw materials are added, the propell...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com