Preparation device of calcium 2-hydroxy-4-methylthio-butyrate

A preparation device, technology of methylthio group, applied in the field of preparation device of 2-hydroxy-4-methylthio-calcium butyrate, can solve the problem of difficult control of reaction speed, pressure and temperature, affecting product yield and quality, and drying of materials Time extension and other problems, to achieve the effect of complete reaction, reduce equipment investment, and dry quickly and effectively

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

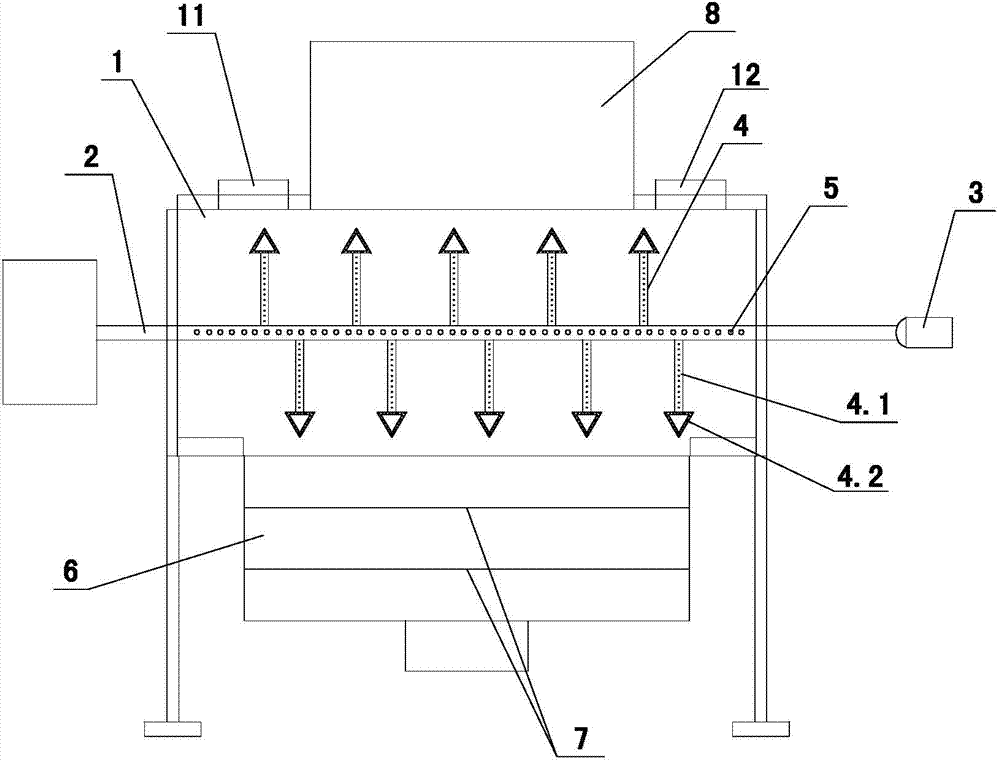

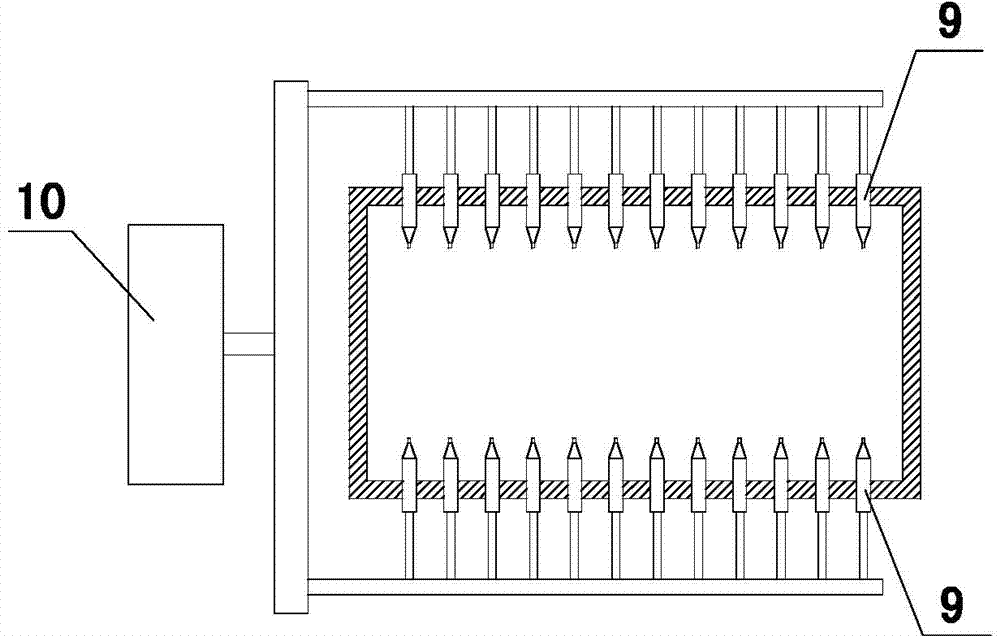

[0016] see figure 1 Shown, the preparation device of 2-hydroxyl-4 methylthio-calcium butyrate of the present invention is characterized in that: comprise drying device, the mixing device with liquid spray device, screening device and control device; Described mixing device Located in the drying device; the liquid spray device is connected to the mixing device; the screening device is located on the lower side of the drying device; the control device controls the drying device, Working of liquid spraying devices, mixing devices and sieving devices.

[0017] The drying device includes a drying cylinder 1; the cylinder wall of the drying cylinder 1 includes a stainless steel plate layer, a steel plate layer and a heating jacket from inside to outside. The stainless steel plate layer is rolled from stainless steel plate. The steel plate layer is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com