Powerful brake device

A braking device, powerful technology, applied in the hoisting device and other directions, can solve the problems of unsatisfactory requirements and small driving force, and achieve the effects of large braking torque, short braking time and reduced power loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

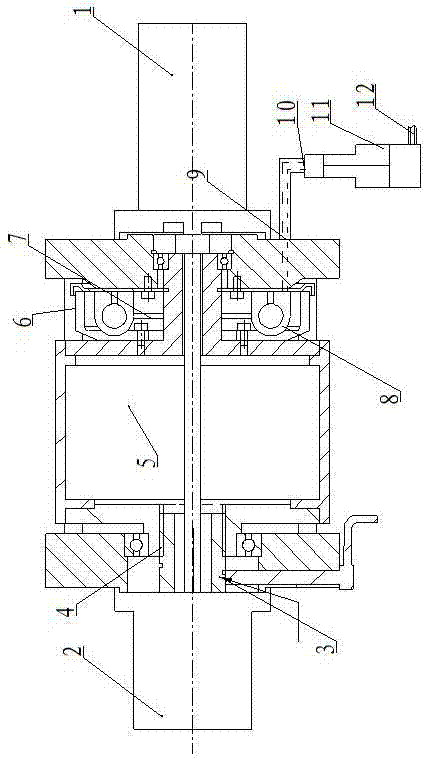

[0014] Such as figure 1 Shown: a strong braking device, which includes a motor 1, characterized in that: the motor 1 is provided with a speed reducer 2, the speed reducer 2 is connected with a clutch 3, and the output end of the clutch 3 passes through The spline 4 is connected to the reel 5, and the reel 5 is connected with a brake device 6, the hub of the brake device 6 is fixed on the reel 5 by bolts, and the brake device 6 is provided with a brake shoe 7 and a pump 8, the sub-pump 8 is connected to a high-pressure oil inlet 9, the high-pressure oil inlet 9 is connected to a high-pressure oil outlet 10, and the high-pressure oil outlet 10 is connected to a gas-liquid booster device 11, and the gas-liquid The pressure booster 11 is connected with a low-pressure gas 12 .

[0015] The invention is simple in design, the motor drives the reducer, the reducer is connected to the input end of the clutch, and the output end of the clutch is connected to the reel through a spline,...

Embodiment 2

[0017] Such as figure 1 Shown: a strong braking device, which includes a motor 1, characterized in that: the motor 1 is provided with a speed reducer 2, the speed reducer 2 is connected with a clutch 3, and the output end of the clutch 3 passes through The spline 4 is connected to the reel 5, and the reel 5 is connected with a brake device 6, the hub of the brake device 6 is fixed on the reel 5 by bolts, and the brake device 6 is provided with a brake shoe 7 and a pump 8, the sub-pump 8 is connected to a high-pressure oil inlet 9, the high-pressure oil inlet 9 is connected to a high-pressure oil outlet 10, and the high-pressure oil outlet 10 is connected to a gas-liquid booster device 11, and the gas-liquid The pressure booster 11 is connected with a low-pressure gas 12 .

[0018] The brake shoe 7 and the slave cylinder 8 are fixed on the upper side of the base.

[0019] The two ends of the reel 5 are respectively provided with a bearing and are fixed on the upper side of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com