Recovering treatment method of waste-flue-gas denitration catalyst

A denitration catalyst, recycling and processing technology, which is applied in the field of recycling and processing waste flue gas denitration catalysts, can solve problems such as unfavorable environmental protection, improvement of comprehensive benefits, reduction of resource recycling, solid waste pollution, etc. The effect of large centralized processing capacity and high recycling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

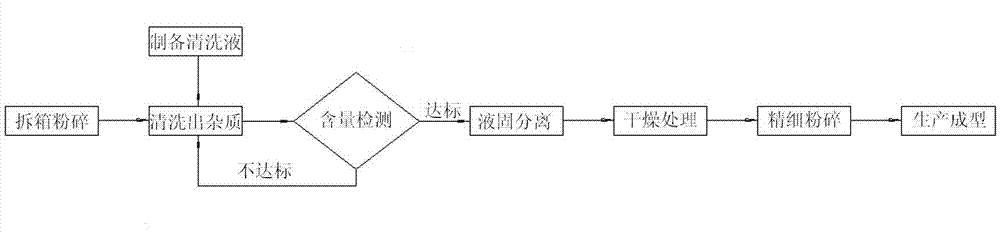

Image

Examples

Embodiment 1

[0017] A method for recovering and treating waste flue gas denitrification catalysts, comprising the following process steps:

[0018] (1) Unpacking and crushing: Use unpacking equipment to disassemble the iron box of the denitrification catalyst module, take out the waste flue gas denitrification catalyst, and use the crushing equipment to finely pulverize the waste flue gas denitrification catalyst to more than 600 mesh, preferably 600 mesh to 700 mesh;

[0019] (2) Preparation of cleaning solution: take 0.1% of the cleaning solution as the penetration enhancer JFC, 0.1% of the cleaning solution as the emulsifier OP-10, and 0.1% of the cleaning solution as the leveling agent Pingpingjiao , sulfuric acid accounting for 1% of the mass percentage of the cleaning solution, 0.1% of the corrosion inhibitor accounting for the mass percentage of the cleaning solution, and the balance being deionized water, mixed with liquid mixing equipment and mechanically stirred for 20 minutes to ...

Embodiment 2

[0026] A method for recovering and treating waste flue gas denitrification catalysts, comprising the following process steps:

[0027] (1) Unpacking and crushing: Use unpacking equipment to disassemble the iron box of the denitrification catalyst module, take out the waste flue gas denitrification catalyst, and use the crushing equipment to finely pulverize the waste flue gas denitrification catalyst to more than 600 mesh, preferably 600 mesh to 700 mesh;

[0028] (2) Preparation of cleaning solution: Take 0.5% of the cleaning solution as penetration enhancer JFC, 0.5% of cleaning solution as emulsifier OP-10, and 0.5% of cleaning solution as leveling agent Pingpingjiao , sulfuric acid accounting for 5% of the mass percentage of the cleaning solution, 0.5% of the corrosion inhibitor accounting for the mass percentage of the cleaning solution, and the balance being deionized water, mixed with liquid mixing equipment and mechanically stirred for 30 minutes to obtain the cleaning ...

Embodiment 3

[0035] A method for recovering and treating waste flue gas denitrification catalysts, comprising the following process steps:

[0036] (1) Unpacking and crushing: Use unpacking equipment to disassemble the iron box of the denitrification catalyst module, take out the waste flue gas denitrification catalyst, and use the crushing equipment to finely pulverize the waste flue gas denitrification catalyst to more than 600 mesh, preferably 600 mesh to 700 mesh;

[0037] (2) Preparation of cleaning solution: Take the penetration enhancer JFC accounting for 1% of the cleaning solution, the emulsifier OP-10 accounting for 1% of the cleaning solution, and the leveling agent Pingpingjia O accounting for 1% of the cleaning solution. , sulfuric acid accounting for 10% of the mass percentage of the cleaning liquid, corrosion inhibitor accounting for 1% of the mass percentage of the cleaning liquid, and the balance being deionized water, mixed with liquid mixing equipment and mechanically sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com