A method for circular flushing of carbon steel pipes in a fine cooling system

A cooling system and pipeline technology, applied in cleaning methods and appliances, chemical instruments and methods, cleaning hollow objects, etc., can solve the problems of poor flushing effect and difficulty in realizing economical and applicable cleaning, and achieve good flushing effect and reduced replacement volume , time-consuming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

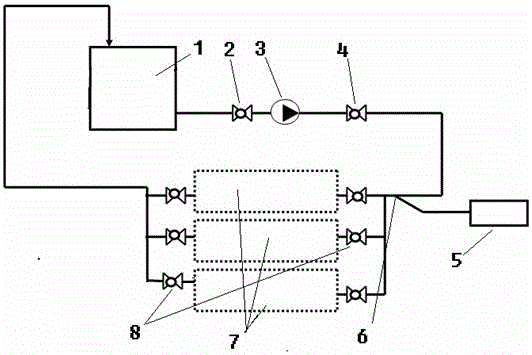

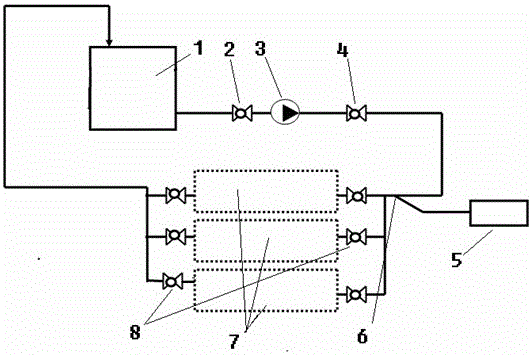

[0032] A method for circularly flushing carbon steel pipes in a fine cooling system, the method comprising the following steps: 1) connecting the carbon steel pipes of different diameters to be flushed in categories and opening at the ends;

[0033] 2) Pass compressed air into the classification pipeline to be flushed for 15 to 30 minutes, and flush out the relatively shallow impurities attached to the inner surface of the pipeline from the opening;

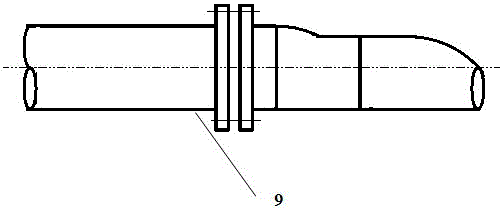

[0034] 3) Put steel balls of different diameters into pipes of different diameters. The number of the steel balls is at least 3. Use compressed air to blow the steel balls from the mouth of the pipe to the inside, and further use the gap between the steel balls and the pipe wall. Contact vibration, so that impurities with low binding force are loosened from the pipe wall and washed out with gas purge; in the steel ball physical vibration step, the compressed air drives the steel ball to flow in the pipe, and at the welded parts su...

Embodiment 2

[0046] As an improvement of the present invention, in the step 7, the steam in the steam turbulence ratio is filled into the pipeline from the circumferential gas distribution port, and blows the steam at the entrance of the carbon steel pipeline to be washed at an angle of 30°~45°. It enters the inside of the pipeline and merges irregularly with the pickling liquid in the pipeline to form a turbulent flow. The advantages of this technical solution are as follows: 1) Through the action of temperature change, thermal expansion and cold contraction, the binding force of the residue in the pipeline is further reduced, so as to remove a large amount of oxide scale and slagging on the weld; Under the action of thrust, the circulation velocity of the cleaning liquid in the pipeline is increased; 3) The cleaning liquid naturally forms a turbulent state under the action of steam, so that the cleaning liquid can fully contact with the substances on the inner wall of the pipe, and the ph...

Embodiment 3

[0048] As an improvement of the present invention, in the step 4, the degreasing treatment is to pass the sodium hydroxide solution at a temperature of 50° C. to 70° C. into the carbon steel pipeline and circulate for 1 to 2 hours. The remaining steps and advantages are exactly the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com