Microporous material loaded ion liquid composite material or film, and preparation thereof

A composite material and ionic liquid technology, applied in the field of invention patents, can solve problems such as limiting the application prospects of liquid films and loss of liquid films, achieve good industrial application prospects, prevent liquid film loss, and improve stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

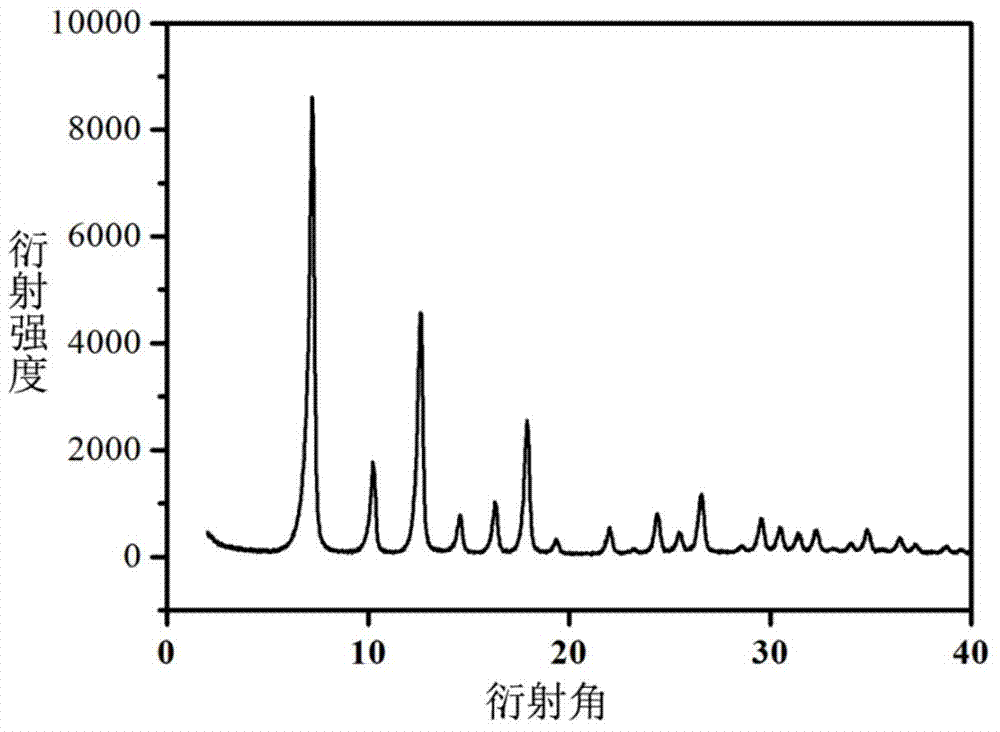

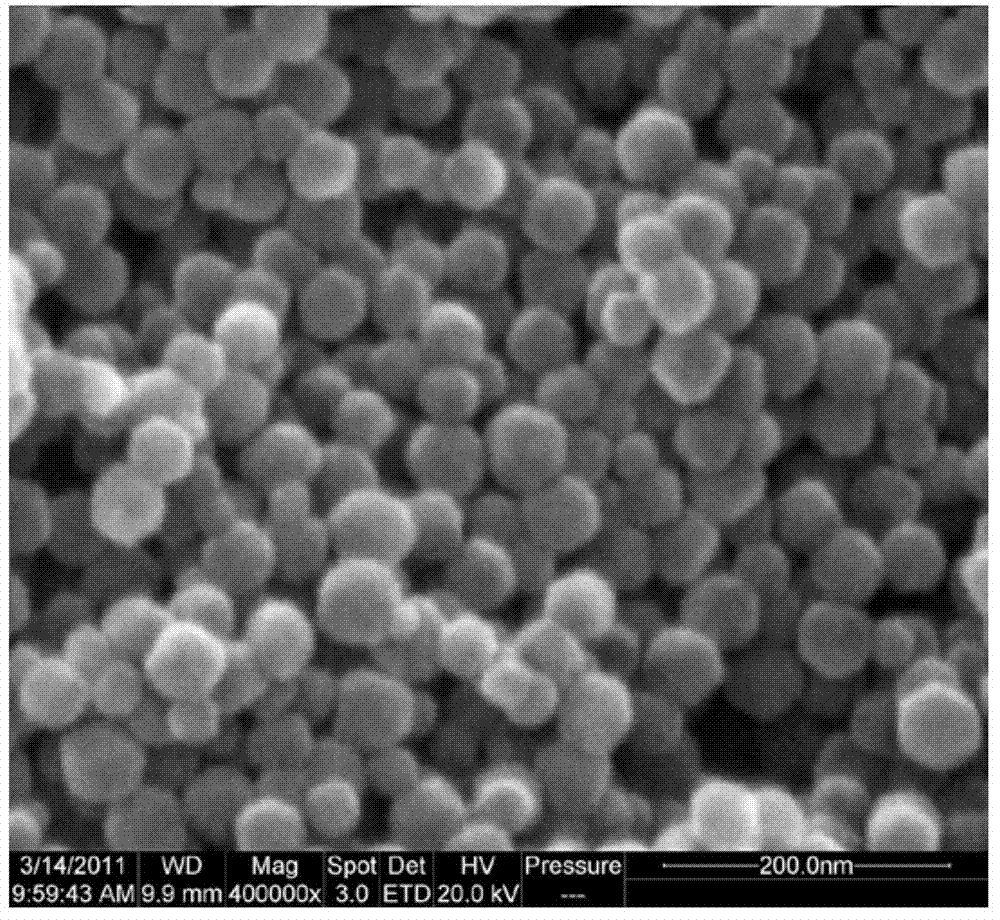

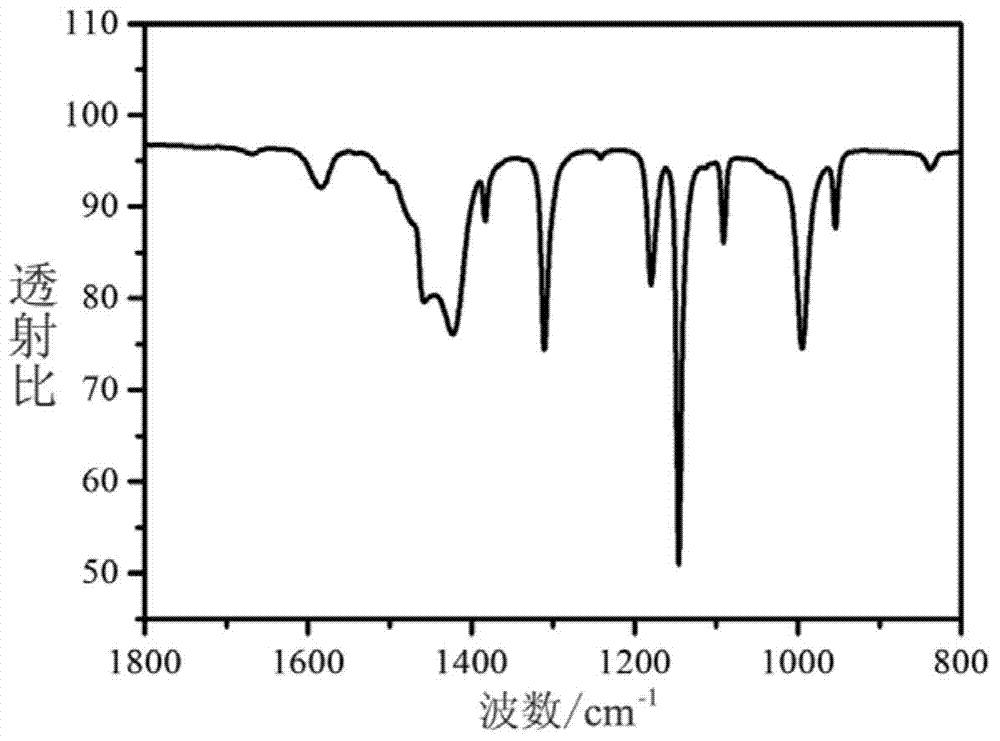

[0064] Embodiment 1 Utilizes in situ synthesis method to prepare ZIF-8 ionic liquid composite material

[0065] Weigh 0.367g zinc nitrate hexahydrate (Zn(NO 3 ) 2 4H 2 O) and 0.811 g of 2-methylimidazole (mim), to the above solid mixture was added 69 g of [bim][PF 6 ] Ionic liquid. This mixture was sonicated for 7200 s in a water bath at room temperature to facilitate the dissolution and interaction of the solid mixture in the ionic liquid. Afterwards, the mixture was stirred at room temperature for 86400 s.

[0066] The reaction mixture was centrifuged at room temperature to obtain the corresponding composite material. The solid was then ultrasonically washed with 20 ml of methanol to remove residual ionic liquid on the surface. And the above washing process was repeated three times. Finally, the product was fully dried in a 60°C drying oven.

[0067] For comparison, the corresponding ZIF-8 nanoparticles were synthesized at room temperature using methanol as solvent. ...

Embodiment 2

[0071] Example 2 ZIF-8 is immersed in ionic liquid and fully stirred to prepare ZIF-8 ionic liquid composite material

[0072] Synthesize ZIF-8 nanoparticles at room temperature, and the molar composition of the synthesis solution is Zn(NO 3 ) 2 4H 2 O:mim:MeOH=1:8:700. To Zn(NO 3 ) 2 4H 2A certain amount of methanol was added to the solid mixture of O and mim and stirred at room temperature for 86400s. After the reaction, the mixture was centrifuged to obtain the corresponding solid, which was ultrasonically washed in methanol to remove unreacted raw materials. The washing process was repeated three times, and finally the obtained solid was fully dried in a 60°C drying oven.

[0073] Dip 0.5g ZIF-8 into 10g[bim][PF 6 ] in the ionic liquid, were stirred at room temperature and pressure for 86400s. Afterwards, the material was separated from the mixture by centrifugation and ultrasonically washed three times with 20 ml of methanol, and finally the obtained solid was ful...

Embodiment 3

[0075] Example 3 ZIF-8 is immersed in ionic liquid / methanol mixture and fully stirred to prepare ZIF-8 ionic liquid composite material

[0076] Synthesize ZIF-8 nanoparticles at room temperature, and the molar composition of the synthesis solution is Zn(NO 3 ) 2 4H 2 O:mim:MeOH=1:8:700. To Zn(NO 3 ) 2 4H 2 A certain amount of methanol was added to the solid mixture of O and mim and stirred at room temperature for 86400s. After the reaction, the mixture was centrifuged to obtain the corresponding solid, which was ultrasonically washed in methanol to remove unreacted raw materials. The washing process was repeated three times, and finally the obtained solid was fully dried in a 60°C drying oven.

[0077] 1.2g[bim][PF 6 ] The ionic liquid and 3.75g methanol were mixed and dissolved to obtain a compatible product, and the mass fraction of the ionic liquid was 24%. 0.5g ZIF-8 was immersed in the mixture of ionic liquid and methanol, and stirred for 3600s and 86400s respecti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com