Composite polypropylene mesh and preparation method thereof

A technology for compounding polypropylene and polypropylene mesh, which is used in medical science, prosthesis, etc., can solve the problems of easy separation, fast degradation of chitosan, and incompatibility between chitosan film and polypropylene mesh. , to achieve the effect of not easy to degrade and induce fascia reconstruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The present invention also provides a kind of preparation method of composite polypropylene mesh, comprises the following steps:

[0029] A) the polypropylene mesh is placed in the dopamine aqueous solution to react to obtain the polydopamine-polypropylene mesh;

[0030] B) The polydopamine-polypropylene mesh is placed in a fibroblast growth factor solution for reaction, and the polypropylene mesh is compounded.

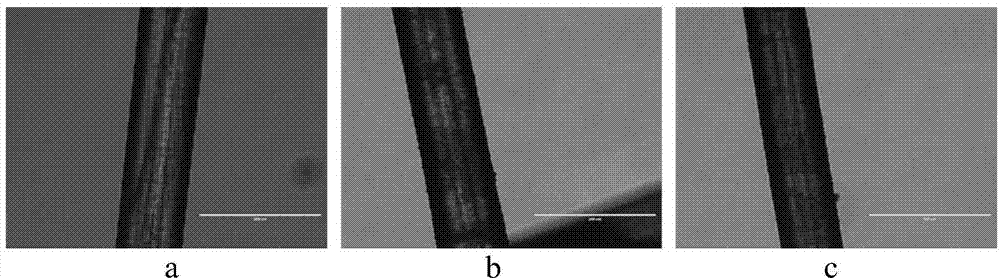

[0031] Before the polypropylene mesh is reacted with the dopamine aqueous solution, the present invention first pretreats the polypropylene mesh, that is, the polypropylene mesh is placed in an ethanol solution with a volume fraction of 75% to 95% for surface treatment , to remove impurities, and can achieve the purpose of sterilization.

[0032] In the invention, the pretreated polypropylene mesh is placed in the dopamine aqueous solution for reaction to obtain the polydopamine-polypropylene mesh.

[0033] The dopamine aqueous solution of the present invent...

Embodiment 1

[0045] The polypropylene mesh is placed in an ethanol solution with a volume fraction of 75% for surface treatment to obtain a pretreated polypropylene mesh.

[0046] Preparation of dopamine solution: 10 mM Tris-HCl buffer solution was used to prepare a dopamine solution with a concentration of 2 mg / ml and a pH value of 8.5. The dopamine aqueous solution is sterilized by filtering through a 0.22 μm filter membrane.

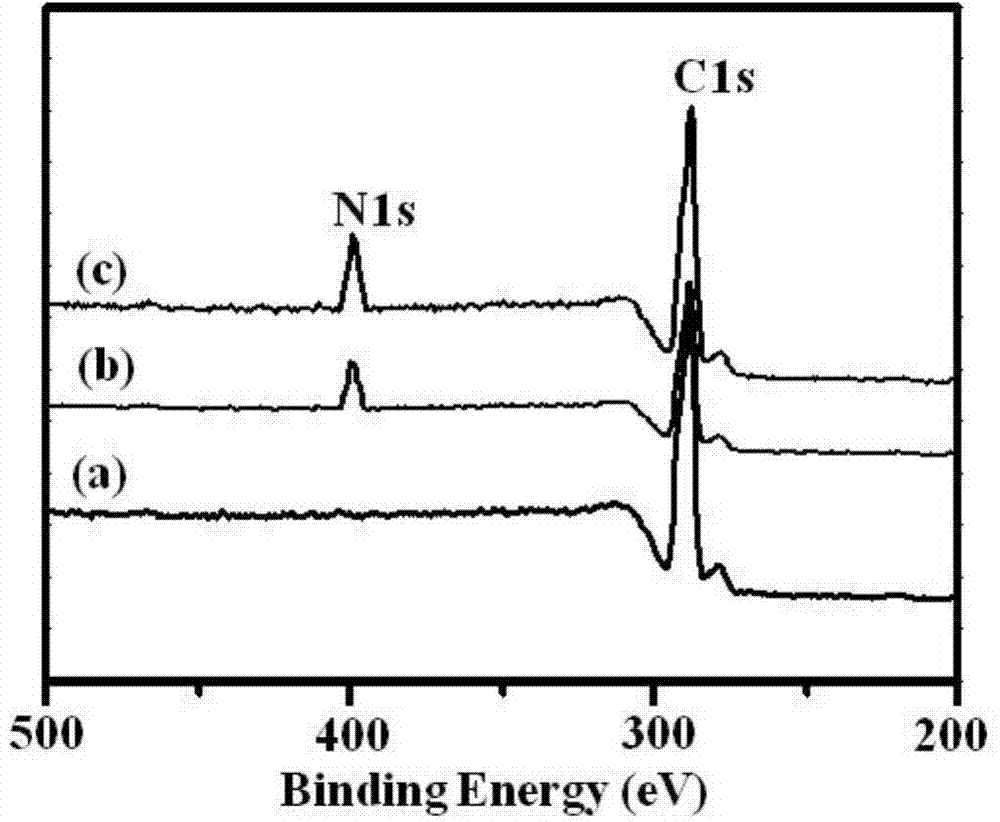

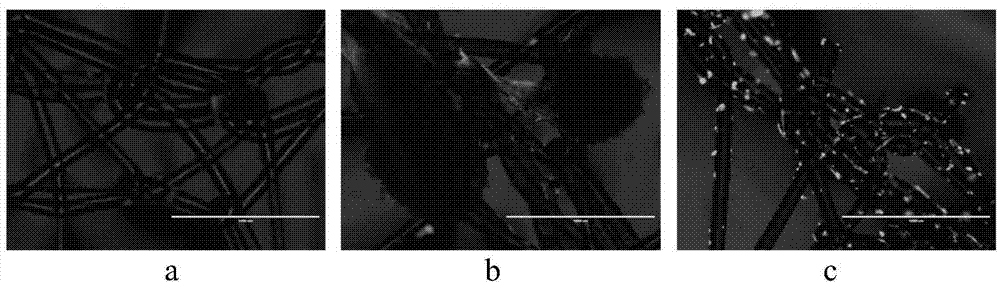

[0047] Soak the pretreated polypropylene mesh in dopamine solution, react at 25° C. for 12 hours, and rinse with deionized water for 5 times to obtain a polydopamine-polypropylene mesh.

[0048] Take out the above-mentioned polydopamine-polypropylene mesh, soak it in the fibroblast growth factor buffer solution with a concentration of 10 μg / ml and a pH value of 8.5, the buffer solution is 10 mM Tris-HCl buffer solution, at 25 ° C After reacting for 12 hours, take it out, rinse it with deionized water for 5 times, and finally dry it with argon flow to obtain a com...

Embodiment 2

[0106] The polypropylene mesh is placed in an ethanol solution with a volume fraction of 75% for surface treatment to obtain a pretreated polypropylene mesh.

[0107] Preparation of dopamine solution: use 10 mM Tris-HCl buffer to prepare a dopamine solution with a concentration of 1 mg / ml and a pH value of 9.0. The dopamine aqueous solution is sterilized by filtering through a 0.22 μm filter membrane.

[0108] Soak the pretreated polypropylene mesh in dopamine solution, react at 25° C. for 12 hours, and rinse with deionized water for 5 times to obtain a polydopamine-polypropylene mesh.

[0109] Take out the above-mentioned polydopamine-polypropylene mesh, and soak it in a fibroblast growth factor buffer solution with a concentration of 15 μg / ml and a pH value of 9.0. After reacting for 12 hours, take it out, rinse it with deionized water for 5 times, and finally dry it with argon flow to obtain a composite polypropylene mesh.

[0110] The properties of polypropylene mesh, po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com