A kind of preparation method of lipophilic sulfur electrode

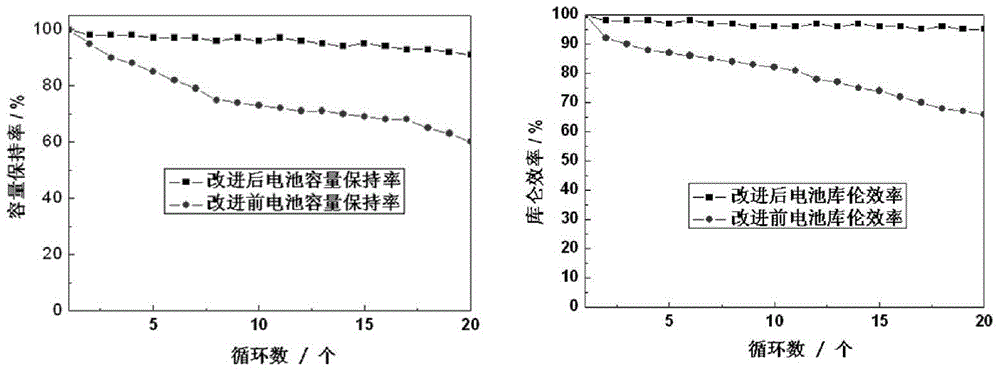

A sulfur electrode and porous electrode technology, applied in the field of lithium-sulfur battery positive electrode and its preparation, can solve the problems of reduced battery discharge capacity, aggravated lithium polysulfide dissolution loss, reduced cycle stability, etc. Efficiency and cycle stability, low cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Add oil furnace carbon (XC-72) and polyvinylidene fluoride to N-methylpyrrolidone at a ratio of 9:1, and fully stir, wherein the solid content is 5%, to obtain slurry A; Evenly coated on Torry060 carbon paper, dried at 90°C to obtain pole piece B, the coating thickness on carbon paper is 10 μm; 50% sulfur-carbon nanotube composite, acetylene black and Polyvinylidene fluoride was added to N-methylpyrrolidone at a ratio of 7:2:1, and fully stirred. Among them, the solid content was 15%, and slurry C was obtained; the slurry C was evenly coated on the pole piece B, and after After drying at a temperature of 50°C, the positive pole piece D of a traditional lithium-sulfur battery is obtained, and the sulfur loading is 3.5mg / cm 2 . Ultrasonically mix methyl hydrogen-containing silicone oil (viscosity of silicone oil is 5Pa·S) and isopropanol at a volume ratio of 1:10 to obtain a silicone oil mixture. On the pole piece, after it is uniformly dispersed, vacuum filter for 20 m...

Embodiment 2

[0028] Add oil furnace carbon (XC-72) and polytetrafluoroethylene into N-methylpyrrolidone at a ratio of 99:1, and fully stir, wherein the solid content is 50%, to obtain slurry A; Uniformly coated on Torry090 carbon paper and dried at 50°C to obtain pole piece B, the coating thickness on carbon paper is 50 μm; 90% sulfur-carbon airgel composite, carbon nano Add tube and polytetrafluoroethylene into N-methylpyrrolidone at 8:1:1, and stir thoroughly, wherein the solid content is 5%, to obtain slurry C; evenly coat slurry C on pole piece B , after being dried at a temperature of 90°C, the positive pole piece D of the traditional lithium-sulfur battery is obtained, and the sulfur loading is 0.5mg / cm 2 . Ultrasonically mix methylphenyl silicone oil (viscosity of silicone oil is 100Pa·S) and carbon tetrachloride at a volume ratio of 1:0.5 to obtain a silicone oil mixture, put the pole piece D on the Buchner funnel, and add the silicone oil mixture dropwise Put it on the pole piec...

Embodiment 3

[0030]Add oil furnace carbon (XC-72) and polyvinylidene fluoride to N-methylpyrrolidone at a ratio of 9:1, and fully stir, wherein the solid content is 10%, to obtain slurry A; Uniformly coated on Torry060 carbon paper, after drying at a temperature of 90°C, the pole piece B was obtained, and the coating thickness on the carbon paper was 10 μm; 50% sulfur-activated carbon composite, acetylene black and poly Vinylidene fluoride was added to N-methylpyrrolidone at a ratio of 9:0:1, and fully stirred, wherein the solid content was 15%, to obtain slurry C; evenly coated slurry C on pole piece B, after temperature After being dried at 50°C, the positive electrode piece D of the traditional lithium-sulfur battery is obtained, and the sulfur loading is 4.5mg / cm 2 . Ultrasonically mix simethicone oil (viscosity of silicone oil is 15Pa·S) and isopropanol at a volume ratio of 1:10 to obtain a silicone oil mixture. On the chip, after it is uniformly dispersed, it is vacuum filtered for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com