Hybrid super capacitor and manufacturing method thereof

A supercapacitor and capacitor technology, which is applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, hybrid capacitor electrolytes, etc., can solve the problem of low energy density of capacitors, and achieve easy industrial application, large capacity, and small internal resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

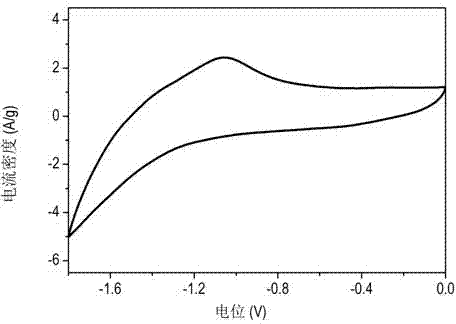

[0032] Mix activated carbon, acetylene black, and polytetrafluoroethylene emulsion at 85 wt%, 10 wt%, and 5 wt%, and coat them on the foamed nickel sheet. Roll the coated nickel foamed sheet with the electrode material and dry it to make a positive electrode. slices; the Fe 2 o 3 Powder, graphite powder and polytetrafluoroethylene emulsion were mixed uniformly at 80 wt%, 15 wt%, and 5 wt%, and then coated on the foam nickel sheet, and the nickel foam sheet coated with the electrode material was rolled and dried and then cut into a negative electrode sheet The positive electrode, the diaphragm and the negative electrode are stacked in sequence to form a compact structure, injecting 1-ethyl-3 methylimidazolium tetrafluoroborate electrolyte, leading out the positive electrode lead and the negative electrode lead, and packaging the shell to form a capacitor.

[0033] The working voltage of the capacitor in this example is 4V, the measured specific capacitance is 40.5 F / g, and the...

Embodiment 2

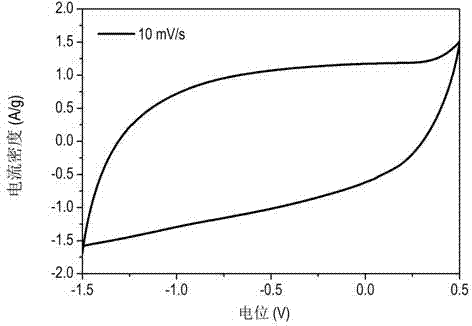

[0035] Graphene, acetylene black and polytetrafluoroethylene emulsion were mixed uniformly at 90 wt%, 5 wt%, and 5 wt%, and then coated on the foamed nickel sheet, and the foamed nickel sheet coated with the electrode material was rolled and dried and then cut into Positive plate; the Fe 2 o 3 / Graphene composite material, acetylene black and polytetrafluoroethylene emulsion are mixed uniformly at 60 wt%, 30 wt%, 10 wt%, and then coated on the foamed nickel sheet, and the foamed nickel sheet coated with the electrode material is rolled and dried before cutting Make a negative electrode sheet; stack the positive electrode, diaphragm and negative electrode in sequence to form a compact structure, inject 1-ethyl-3 methylimidazolium hexafluorophosphate electrolyte, lead out the positive electrode lead and negative electrode lead, and package the outer shell to form a capacitor.

[0036] The working voltage of the capacitor in this example is 4V, the measured specific capacit...

Embodiment 3

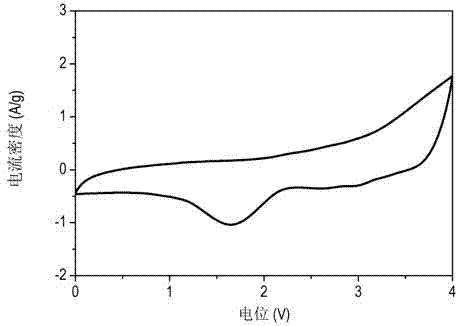

[0038] Mesoporous carbon, acetylene black and polytetrafluoroethylene emulsion were mixed uniformly at 85 wt%, 10 wt% and 5 wt%, and then coated on metal aluminum foil, and the aluminum foil coated with electrode material was rolled and dried and cut into positive electrodes slices; the Fe 2 o 3 / Activated carbon composite material, acetylene black and polytetrafluoroethylene emulsion are mixed uniformly at 40 wt%, 50 wt% and 10 wt%, and then coated on the foamed nickel sheet, and the foamed nickel sheet coated with the electrode material is rolled and dried and then cut into Negative electrode sheet: stack the positive electrode, diaphragm and negative electrode in sequence to form a compact structure, inject 1,3-dimethylimidazolium tetrafluoroborate electrolyte, lead out the positive electrode lead and negative electrode lead, and package and assemble the capacitor into a capacitor.

[0039] The working voltage of the capacitor in this example is 4V, the measured specif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com